January 18, 2019

Storing and shipping frozen drug substances – why single-use systems are the optimal solution

At Single Use Support we have been pondering the processing and – more importantly – the storing and shipping of frozen biopharmaceutical substances utilizing single-use solutions. Our developments on the basis of single-use bioprocess containers offer manufacturers of biopharmaceuticals an almost 100% reliable logistics process for liquid substances such as single-use bags. This is also to provide maximum safety and efficiency for shipping and storing biopharmaceuticals of high value.

Storing & Shipping with single-use systems

In order to understand why single-use technology is so relevant in the supply chain of several therapeutics beyond the steps of freezing and shipping, one has to bear in mind what characterizes the biotechnology market. It has become standard procedure to geographically detach the processing of biopharmaceutical substances (e. g. bulk drug substances) from the production of the final medicinal drug product: Large batches of the active ingredient are being manufactured at one location; the ingredient is then divided into many smaller frozen units that are shipped to various sites around the globe for the final processing.

Read more: Drug substance vs. drug product – the differences

By now, integrated single-use freeze-thaw systems with single use bags, hoses and connectors have become standard as they offer higher efficiency and flexibility while at the same time being more cost-effective. The ideal frozen storage and shipping solution for biopharma.

The freezing of biopharmaceutical substances in single-use containers offers manufacturers of biopharmaceutical drugs the following advantages:

- increased range

- increased process flexibility and efficiency

- reduced demand for capital

- reduced labor costs thanks to processing in batches

- increased number of patients treated in a shorter period of time

- no cleaning and sterilization required for single-use systems

- reduced maintenance and validation times

- large volumes of expensive drug substances can be frozen in batches to facilitate the production of medicinal drugs on the basis of commercial or clinical real-time requirements

The same applies to autologous cell therapies like CAR-T. In order to safeguard patient safety, a smooth shipping process is imperative. The concerned patients’ cells are collected at the hospital and then sent to the lab for manipulation before being returned to the hospital for injection.

Time and safety play a crucial role. Due to their already mentioned advantages, single-use technologies can contribute to an improvement of ailing patients who receive cell or gene therapies.

Freezing drug substances for storing and shipping

Basically, it is far more reliable and practical to store and ship biopharmaceutical liquids in a frozen state. Medicinal drugs made of big molecules are particularly prone to being damaged – and damages can be prevented by freezing valuable liquid drug substances. Like this, the drug’s biological integrity is preserved while necessary logistical measures are organized. Furthermore, freezing ensures the quality of biopharmaceutical products in-between the separate production steps.

Frozen substances make it significantly easier to comply with temperature check requirements. In addition, frozen biopharmaceuticals through a pharma freezer have less interaction with their containers than non-frozen liquid substances, plus mechanical stress can be clearly reduced. There is no more need to move giant containers between premises or even between countries.

The integrity of liquid substances is particularly important in case of gene-, cell- and tissue therapies. All of those therapies are expensive and valuable. Factors such as time and patient safety play major roles.

Storing frozen drug substances – what freezer to choose

For the storage of frozen drug substances, adequate devices need to be put into place to create ideal conditions for the processed drug substances along the entire cold chain. As many biopharmaceuticals need to be stored at low temperatures far below 0 °C, manufacturers need to decide on what freezing method to choose. Nevertheless, the freezing process must not influence product stability or product quality, e. g. by unwanted protein aggregation or denaturation within protein solutions.

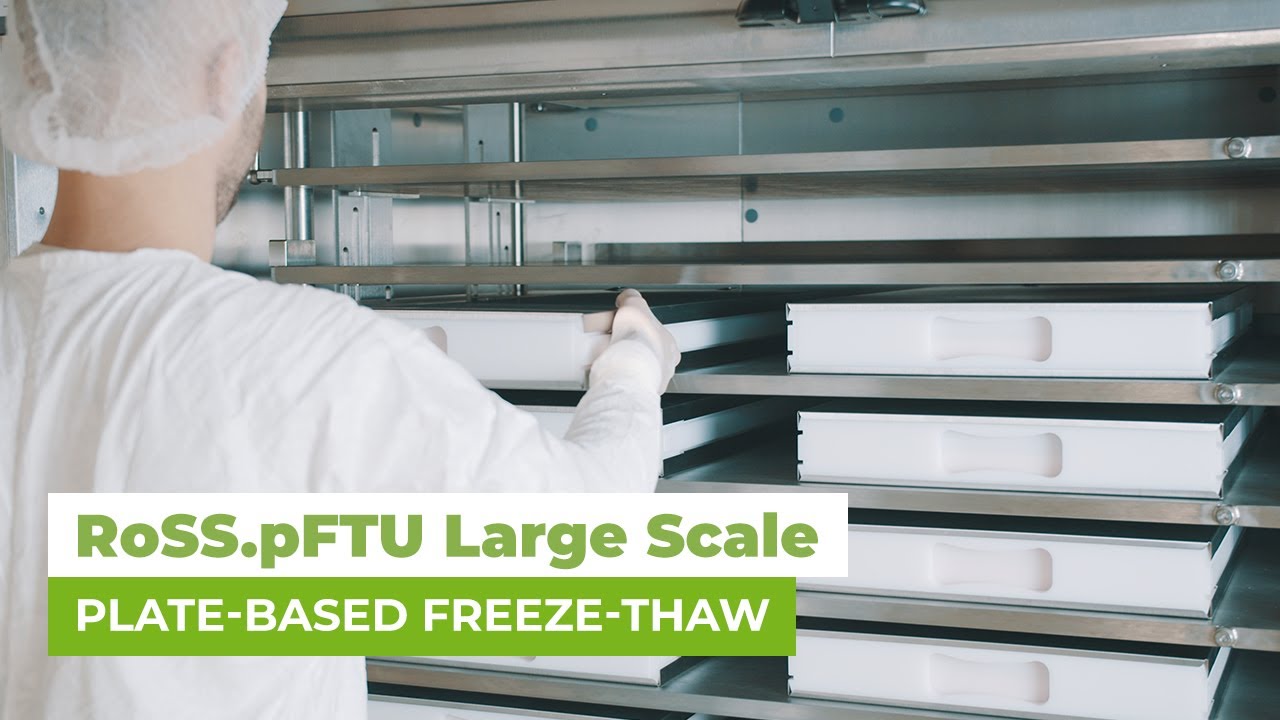

Single Use Support has developed a specialized freeze-thaw platform – available in different sizes, from small-scale to large-scale. The platform is based on plate freezing, able to deliver fast freezing rates by a controlled heat transfer. This is to avoid effects like cryoconcentration, which might occur on certain products when slow freezing rates are chosen.

To maximize shelf life, several biopharmaceuticals must not only be stored in a refrigerated, but in an ultra cold temperature-controlled environment, feasible for their long-term storage – certain vaccines, for instance, but also monoclonal antibody (mAb) products. As temperature stability is key and temperature excursions must be avoided, high-performance storage freezers need to be chosen that both comply with regulatory demands and deliver a maximum of robustness in order to provide a safe space for biologics during storing and shipping.

Within the process development of temperature-sensitive biopharmaceuticals, biotech companies and manufacturing facilities need to deliberate the thawing process with as much diligence as any other process step in the manufacturing process (e. g. extractables and leachables testing). The functionality to adjust thawing rates, special needs for different protein formulations and much more has to be considered at the choice of the right thaw technology to guarantee seamless freeze and thaw cycles, reducing the risk of product loss to a minimum.

Download our whitepaper: How controlled & scalable freezing becomes reality

The advantages of freeze-thaw solutions based on single-use technologies

Single-use freeze-thaw systems contribute to a simplified quality management for biopharmaceutical liquids. Contrary to freeze-and-thaw processes in stainless steel tanks or bottles the risk of cross contamination is significantly reduced when using single-use solutions. Manual interventions during the freezing and thawing processes, as well as during handling and shipping become void.

Liquid substances contained in single use bags can be frozen and thawed more consistently, which leads to a more homogenous compound of biological components and – as a result – to a far more stable product. This is a result of the reduced distance from the container’s edge to its center. Furthermore, it is easier to store single-use bags than stainless steel reactors – they can simply be stored in freezers of varying sizes.

Read more about frozen storage and shipment in Biopharma with RoSS® Shell.

Storing and shipping frozen drug substances – scalability is key

When storing and shipping frozen drug substances, scalability and flexibility are essential. The transition from a scale-down model to bulk production may be challenging and bound to certain costs. This is why scalable platform solutions are frequently chosen, in that they can easily be adjusted to changing requirements.

A great deal of flexibility is also required considering that cold storage is associated with costs. Efficient space management is, therefore, essential for maximizing efficiency when shipping frozen drug substances. Yet again, scalable end-to-end platforms based on single-use technologies can play out their strengths, as they bring a maximum of compatibility. The ultra-cold storage freezer RoSS.FRDG by Single Use Support, e. g., is fully stackable and brings high storage density for bioprocessing containers protected by RoSS Shell.

Shipping frozen drug substances - our solutions

For shipping purposes, biopharmaceutical substances are normally stored at temperatures between -4 and -112 degrees Fahrenheit (-20 and -80 Grad Celsius). A successful freeze & thaw process requires a thorough check of the single-use system’s physical and thermal properties as well as the substance’s integrity and quality.

In order to guarantee all of the above, tried-and-tested, well-built and robust single-use systems are required. They should have been thoroughly tested in real-life conditions, taking into account normal and abnormal scenarios such as variations in temperature. The best validation results can always be achieved in cooperation with your supplier’s scientists and engineers.

Apart from the single-use bag containing the liquid, the protective sleeve (single-use bag protection), hoses and connectors as well as the secondary packaging need to be designed to protect the valuable content not only throughout the entire shipping process but also its entire life cycle.

At Single Use Support we offer exactly that: Precise and tested single-use systems that offer a reliable freeze-thaw process and in addition cover the entire logistics process. And what is even more: Our standalone systems are maximally scalable and efficient, irrespective of the brand of single-use bags you use. Why don’t you see for yourself? This video shows you our entire end-to-end process.

FAQs about storing and shipping drug substances

What are the advantages of frozen drug substance over liquid storage?

Important advantages of frozen drug substance over liquid storage are reduced bioactivity in certain biopharmaceuticals (especially important for long-term storage) and potentially higher product stability during transport.

What is freeze-thaw drug stability?

Freeze-thaw stability describes the ability of biopharmaceuticals to preserve product quality while undergoing extreme variations in temperature, as they occur (in a controlled manner) during freezing and thawing processes necessary for their shipping and storing.

What is primary and secondary packaging?

The primary packaging is the packaging that comes into direct contact with the pharmaceutical products. A secondary packaging is the outer packaging, which provides extra protection to the primary packaging during storage and transportation to reduce the risk of breakages of the primary packaging. Read more in the article: primary and secondary packaging for drug substances

Storing and shipping with RoSS.SHIP - Case Study