December 21, 2020

Efficient freezing and thawing of vaccines with single-use technologies

Vaccines are a hot topic right now, and the need for protection against the Corona virus has resulted in a race to bring effective vaccinations to the market before the end of the year. While a vaccine will only become reality thanks to extensive research and development, reliable and safe logistics processes play an equally important role so that the end result can eventually be shipped to all corners of the globe in a safe and reliable manner.

SUSupport is on the forefront with highly efficient end-to-end solution based on single-use technologies, such as Freeze Thaw technology, safe logistics system and integrity testing of drug substances. Read more about the advantages in the following article.

Easy and safe handling and storing of vaccines

Single use technologies offer a number of advantages that cover the entire biopharmaceutical process, including development, manufacturing and logistics. Due to the highly flexible and scalable nature of single use components, handling becomes very easy while acquisition and storage costs can be reduced significantly. Those are decisive factors when time is of the essence in producing a new serum and distributing it globally.

With reliable cold chain logistics processes based on advanced single use technologies, a safe and protected handling of the highly valuable and sensitive vaccines - and other pharmaceutical substances - can be guaranteed. They contribute to a safe journey and warrant the single use bag’s intact arrival at its final destination, keeping its precious contents protected from biocontamination and other damages.

Controlled filling, filtration and freezing

The global distribution of any medical substance requires more than what meets the eye. Before a vaccine can finally be shipped it needs to be safely processed and contained (or packaged, if you will) - just like an oyster. Temperatures as low as -80 °C (-62 °F) can lead to an excessive waste of materials and resources as they can cause single use bags to rupture and materials to break. This is why it is imperative to protect the single use bag with its valuable content during the entire journey, starting with the three Fs: controlled filling, filtration and freezing.

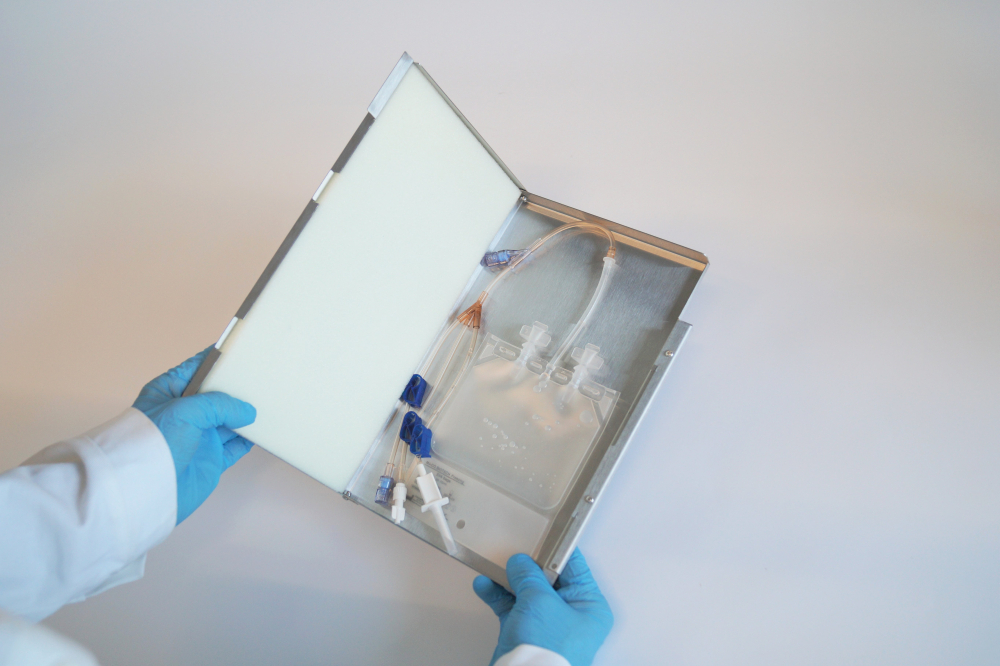

Taking inspiration from an oyster, Single Use Support has developed a compact shell to protect the single-use bag during storage, shipping and the freezing process. The shell is made of high-quality stainless steel that offers protection against external impact, while on the inside the bag is bedded in specially developed soft 3D foam. In line with the requirements of a fast-paced market, Single Use Support’s RoSS Shells are tamper-proof and compatible with single use bags of all established brands and manufacturers.

Safe and fast freezing, thawing and draining

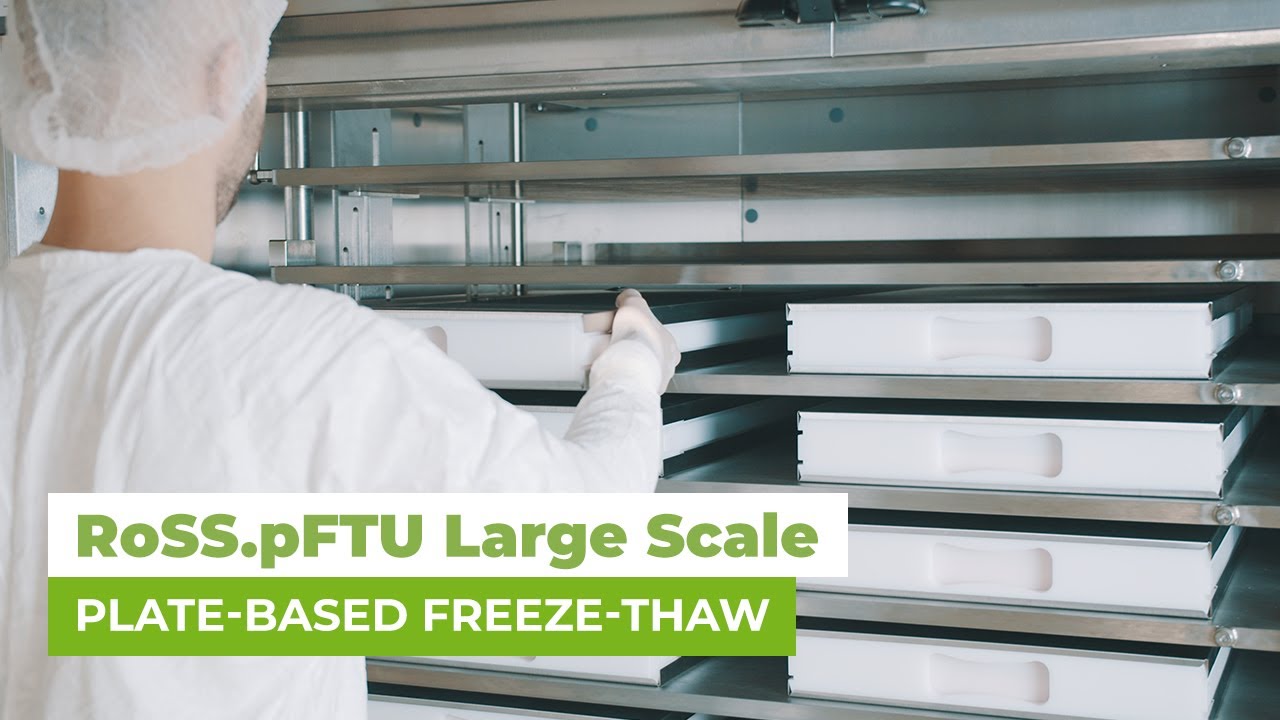

While static freezers may still be the norm, more flexible and faster plate freezing platforms such as Single Use Support’s RoSS.pFTU are gaining traction. The slow freezing process of traditional freezers impacts the medical substance’s quality. It leads to the formation of large crystals that can cause friction and will increase cryoconcentration. As a result, up to 20% of proteins can get destroyed.

On the other hand, controlled rate plate freezers for biopharma not only speed up the freezing process; more importantly, the increased freezing rate also leads to better results, meaning that the substance’s characteristics will be maintained in the best possible way. Plate freezers facilitate a speedy and at the same time controlled freezing of valuable vaccines and other liquid solutions contained in the single use bag and protected by the tamper-proof RoSS Shell.

Additionally, RoSS.pFTU offers the added benefit of not only providing an advanced freezing technology, but also controlled thawing and draining - all with a single, flexible and scalable platform.

Read more about freezing of drug substance, thawing of drug substance or advanced cold chain solutions for vaccine development

Additional protective measures

Coolable shipping and storage containers:

In order to maintain the cooling chain throughout the entire shipment and storage process, specialized shipping containers are required. Single Use Support provides compact coolable shipping and storage containers to keep the RoSS Shells and their contents cool once they have been frozen. Those containers are made of stainless steel and can carry up to 20 RoSS Shells. The cooling system inside the isolated containers is based on dry ice or so-called “Phase-Change Materials” (PCM).

All containers are equipped with GPS chips, so they can be tracked and localized throughout their journey. At the same time those chips allow for a constant monitoring of the temperature inside the containers to guarantee for a reliable and safe frozen bag shipment.

Integrity testing kit:

Deficient single use bags can lead to contamination with bioburden and endotoxins, and in the worst case scenario the entire content of the bag will be rendered useless. As such, deficient single use bags pose a safety risk that can be easily avoided.

So as not to compromise the quality of highly valuable vaccines before they have even left the lab or plant, all bags should be tested regarding their integrity. The integrity test kit MITS.2D is based on helium and allows for the detection of microscopically tiny holes in the bags.

Protect your valuable substances by utilizing advanced single use technologies and ensuring your goods’ intact arrival at their intended destination!