BIOPHARMA PROCESSES

Advanced Fluid Management and Freeze/Thaw Logistics

We close the gap between downstream and the fill & finish process in the biopharma industry with the use of single-use technologies. At Single Use Support we offer biopharma companies access to a new and almost 100% secure drug substance logistics process for their filling, freezing, thawing and logistics processes.

Our developed technologies increase patient safety and minimize the risk of bio contamination and product loss significantly. We build upon standards, eliminate material deficiencies, and minimize human errors.

Storage and shipping of high-value substances such as APIs (active pharmaceutical ingredients), buffer, media, biojoncugates, vaccines, cells or other liquids can be performed faster and more safely than before.

Fill/Filtration-Freeze/Thaw

cGMP-compliant single-use technologies enable standardization in critical process steps where a large technology gap exists in biopharmaceutical production.

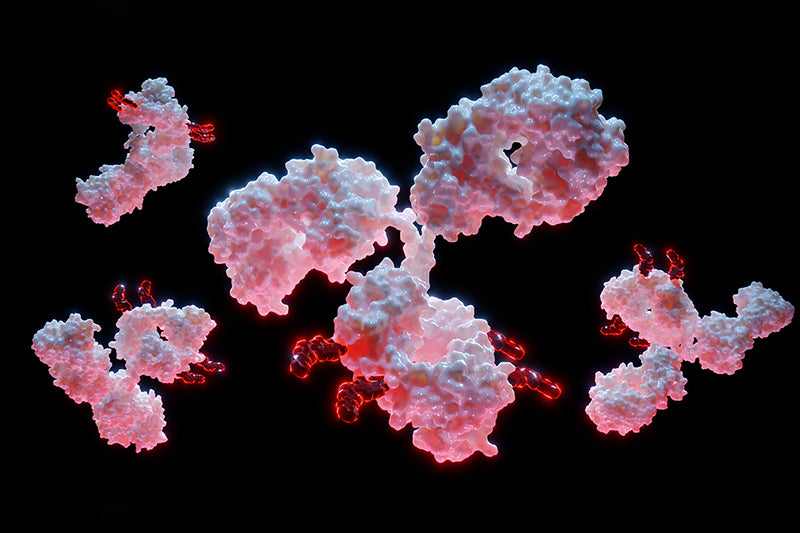

Safe Handling of Monoclonal Antibodies (mAbs)

Controlled processes play a vital role for monoclonal antibodies (mAbs) manufacturing processes. mAbs require special care and sensitive handling at every step of the development and production, as well as in logistics, so as not to compromise their effectiveness.

Messenger RNA (mRNA)

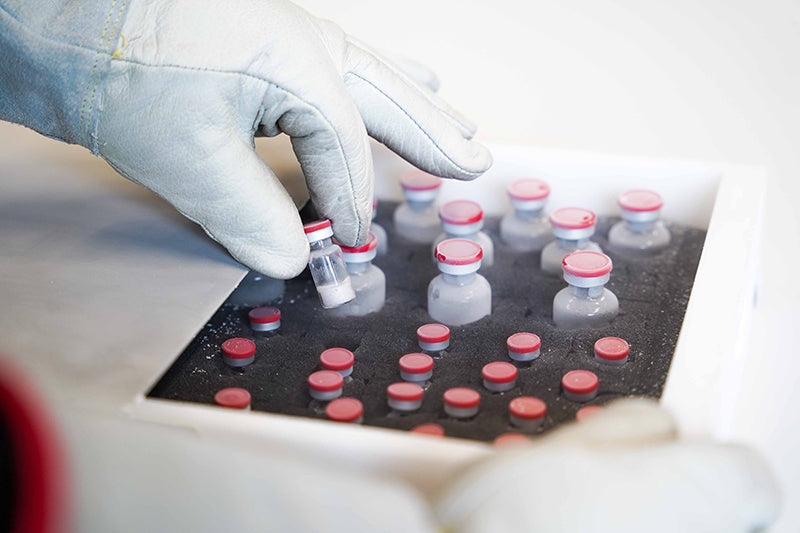

Temperature plays a key role in the Messenger RNA (mRNA) supply chain, as single doses biotherapeutics or vaccines must be kept at temperatures similar to those used in their clinical trials: -70°C (-94°F).

Bioconjugates

Bioconjugates represent a rising class of biopharmaceuticals wherein at least one of the reactants is a biomolecule, often an antibody, protein, or oligonucleotide. The most famous example is the class of antibody-drug conjugates (ADCs).

Vaccines

Single-Use Technolgies offer the best advantages to guarantee the needs in today's vaccine production. Due to the highly flexible and scalable nature of single-use components they cover the entire biopharmaceutical manufacturing process, including upstream, downstream, fill-finish and the gaps in-between.

Fermentation

Cold Chain Handling for Microbial, Bacterial & Mammalian Fermentation. For improved fermentation production, manufacturing suites must be equipped with scalable, cost-effective and robust process solutions for large volumes up to hundreds of liters per batch.

Cell Banking

In the process of creating new drug compounds cells play an important role. However, handling of cells requires very carefull and fast processes in order to guarantee best-possible quality.