Welcome to Single Use Support

Reduce product loss with a trusted partner

We provide advanced fluid management solutions around single-use technologies for the Biopharma Industry to increase patient safety. Discover our products around primary packaging, single-use bag protection, freeze-thaw processes, single-use filling-filtration, and logistics of your substances.

MODULAR AND CUSTOMIZABLE SOLUTIONS - FOR ALL MODALITIES

-

Fluid Management for Biopharma Processes

More InformationWe close the gap between downstream and the fill & finish process in the biopharma industry with the use of single-use technologies. At Single Use Support we offer biopharma companies access to a new and almost 100% secure logistics process for their freezing, thawing and logistics processes.

-

Fluid Management for Advanced Therapies

More InformationBy providing modular standards and highly customizable solutions,we support you in writing a new chapter in advanced therapy medicinal products (ATMPs): Our single-use technologies and sterile consumables come with the flexibility required for fast turnaround times in advanced therapeutics

Our customers trust in us:

CONSUMABLES

-

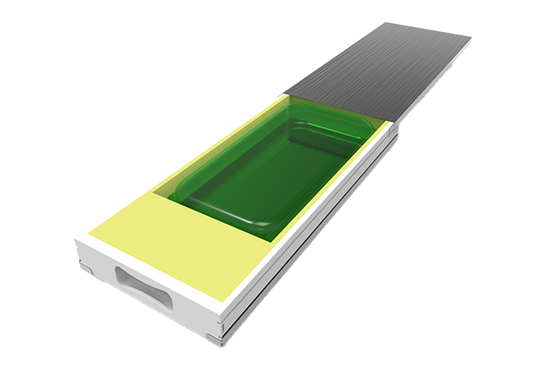

Protecting single-use bags | RoSS® Shell

The safest transport solution for all available single-use bioprocess containers. Protect your single-use bag and reduce product loss. RoSS®: Robust Storage & Shipping

Bag independent

Reduced product loss

Best freezing result

-

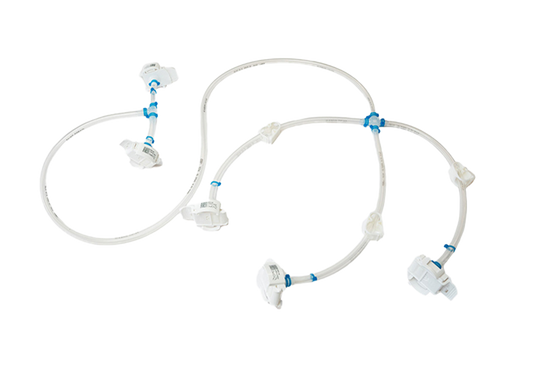

Biopharma fluid transfer | IRIS Single-Use Assemblies

As an expert in single-use solutions, we have made it our goal to deliver vendor agnostic single-use assemblies manufactured at highest quality standards in ISO 7 cleanrooms and sterilized within shortest lead times. Prevent downtime and ensure an...

100% customizable

Dual sourcing

GMP-compatible

-

2D bioprocess container | IRIS Bag

Innovative. Robust. Individual. Single-Use. Make sure your supply chain is uninterrupted. Get your IRIS 2D single-use bioprocess container from Single Use Support in any size with the fastest possible delivery times. Store and ship anything from c...

Sizes from 20mL-10L

Freezing to -85°C

Reliable partner

-

Cold chain container for drug substances | RoSS.SHIP

RoSS.SHIP secures the cold chain storage and shipping of bulk drug substance for almost one week. With its Smart Tracking & Tracing Add-on you never loose control of your product. Highly robust, stackable, coolable and compact – RoSS.SHIP co...

Below -60°C for at least 6 days

Track & trace 24/7

Up to 55 RoSS® shells

-

Stainless steel trolley for RoSS® shells | RoSS.TRLY

The RoSS.TRLY is a supporting device for the in-plant transport of up to 30 RoSS® shells. The RoSS.TRLY is a stainless steel trolley that can be easily moved to smoothen the process between various logistics units or manufacturing steps, such as ...

Up to 30 RoSS® shells

Suitable for cleanroom

100% customizable

PLATFORM SYSTEMS

-

Homogenizing and cooling system | RoSS.PADL

RoSS.PADL is a scalable massaging and mixing system for achieving a uniform mixture in single-use bags. With integrated cooling and heating, it maintains optimal temperatures consistently. This makes it well suited for applications such as cell &a...

Bag independent

Consistent homogeneity

Temperature control

-

Aseptic filling system | RoSS.FILL Bag

RoSS.FILL Bag is a flexible automated aseptic filling machine for the aliquotation and dispensing of bulk drug substance (BDS) into single-use bags. The system for aseptic filling and sterile filtration is highly precise, making RoSS.FILL Bag an e...

Up to 400L+/Batch

Highest accuracy

Fast throughput

-

Plate freezer biopharma | RoSS.pFTU Large-Scale

Single Use Support's large scale system is a plate-based freeze-thaw unit for any scale and batch size. The system is compatible with single-use bags of all sizes and manufacturers and enables a controlled process down to -80°C of up to 400L per b...

Down to -80°C

Controlled freeze-thaw

Up to 400L+/Batch

-

Blast freezer for pharmaceuticals | RoSS.BLST

RoSS.BLST is a GMP-compatible system for blast freezing & thawing of drug substances. It is suitable for any primary packaging from all manufacturers and allows freezing and thawing within a temperature range of -80°C to +40°C. The modular and...

Capacity for up to 300L

Modular Interior

Down to -80°C

-

Cryogenic freezer | RoSS.LN2F

RoSS.LN2F is a powerful cryogenic controlled rate freezer for cryopreservation down to -170°C. An enclosed and innovative platform system for dosed freezing for cell and gene therapies eliminates direct exposure and the need for mechanical compres...

Increased cell viability

Down to -170°C

Down to < 250mL/ Bag

-

Laboratory freezer | RoSS.pFTU Lab-Scale

Single Use Support's plate-based laboratory freezer is the perfect solution for clinical studies conducted in labs and, above all, if you want to start a controlled and scalable cGMP freezing & thawing process. The system is compatible with si...

Down to -80°C

Controlled freeze-thaw

Up to 10L

-

Ultra-low temperature storage freezer | RoSS.ULTF

RoSS.ULTF is an upright ultra-low temperature storage freezer for frozen drug substances in different sizes. The ultra cold storage freezer keeps the desired set point temperature down to -80°C. It is compatible with RoSS® Shells to protect your ...

Down to -80°C

Capacity for up to 300L

Modular Interior

-

PUPSIT system | RoSS.PPST

RoSS.PPST is an advanced PUPSIT system that tests the integrity of up to two filters used in biopharmaceutical manufacturing. It verifies filter integrity after sterilisation and prior to aliquotation, meeting EU GMP Annex 1 relevant quality stand...

100% customizable

Fully automated

GMP Annex 1 compatible

-

Draining system for Single-Use Bags | RoSS.DRAI

This standalone single-use bag draining system improves emptying single-use bags on site. Connected peristaltic pumps enable controlled fluid flow and the lowest possible retention volume. Multiple racks can be connected, allowing several single-u...

Up to 60 Bags

Minimum hold-up volume

Aseptically closed system

-

Single-use thawing & shaking system | RoSS.SHAK

RoSS.SHAK is your reliable shaker to regain the highest quality and homogeneity of the drug substances in single-use bags placed in RoSS shells. The movement and the desired speed settings allow a smooth thawing and agitation of the drug substanc...

Product homogeneity

Up to 240L per run

Bag independent

TELL US YOUR NEED!

NEWS

Learn all about Single Use Support & our innovations

-

Company

About usSupporting single-use systems in biopharma, Single Use Support revolutionizes the management of drug substances at sub-zero temperatures and during handling processes.

Closing gaps between Downstream and Fill & Finish Single Use Support offers an innovative and 100% secure logistics process ensuring better support for the pharma industry.

-

Applications

See all applicationsCutting-edge technologies from Single Use Support are applicable anytime when liquid biopharmaceuticals are being frozen and transported – ranging from small volumes in clinical studies for ADCs, viral vectors, mAbs, mRNA up to commercial large volumes of bulk drug substance.

-

Ask our engineers

Contact usStriving for scalable solutions? Solutions that are integrated into a fully end-to-end solution process? Irrespective of the type of single-use bag used? And not worrying about product loss?

Single Use Support owns the expertise to fully support your requirements.

-

Solutions

See all solutionsOur product solutions cover the whole liquid management process starting from packaging in bags, protecting with save shells, filling via manifold assemblies and fill/filtration platforms, up to cold chain management with controlled freezing & thawing, ultra cold freezing and reliable shipping.