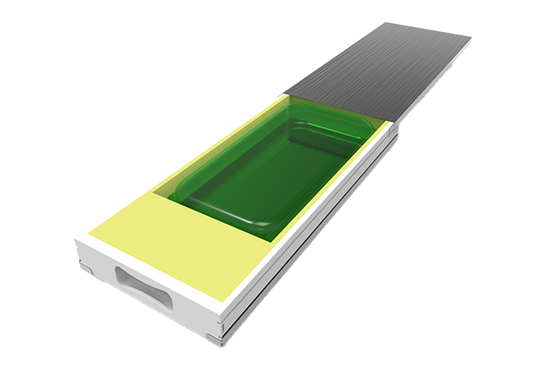

Plate freezing & thawing

Blast freezing & thawing

Crogenic freezing

Ultra-low temperature storage freezer

Complementary products

Downloads

Guide: Scale overview RoSS.pFTU

Please fill out the form below to download this file.

Guide: Scale overview RoSS.pFTU

Whitepaper: RoSS.pFTU - Controlled scalable freezing

Please fill out the form below to download this file.

Whitepaper: RoSS.pFTU - Controlled scalable freezing

Case Study RoSS.pFTU: The ROI of Bulk Freezing with Plate Freezers

Please fill out the form below to download this file.

Case Study RoSS.pFTU: The ROI of Bulk Freezing with Plate Freezers