VACCINES

Cold Chain Handling in Vaccine Manufacturing

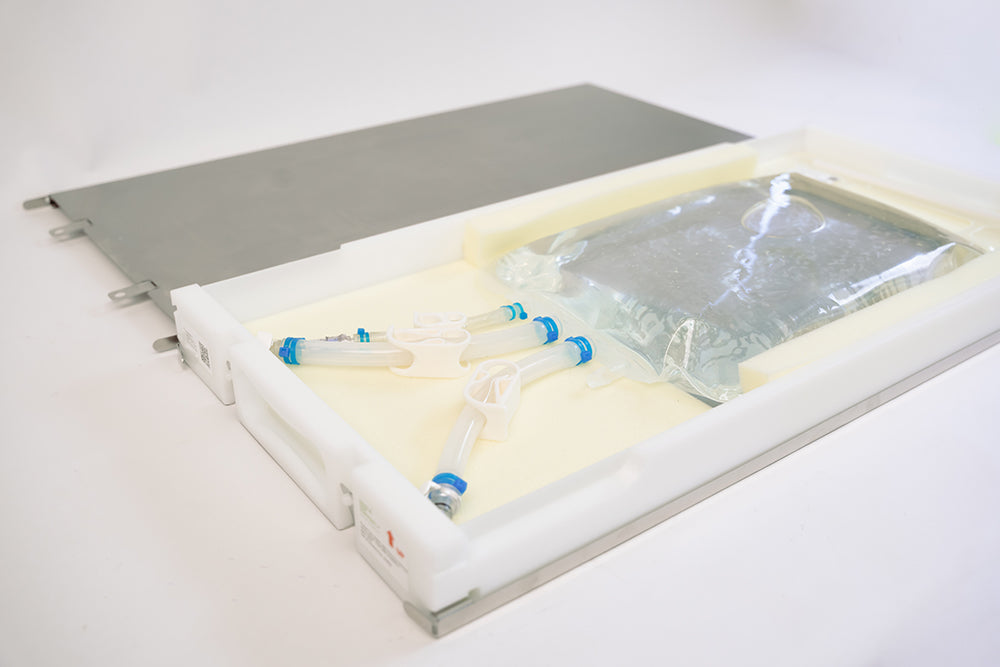

Single-Use Technolgies offer the best advantages to guarantee the needs in today's vaccine production. Due to the highly flexible and scalable nature of single-use components they cover the entire biopharmaceutical manufacturing process, including upstream, downstream, fill-finish and the gaps in-between.

With reliable cold chain processes based on advanced single-use technologies, a safe and protected handling of the highly valuable and sensitive vaccines can be guaranteed. They contribute to a safe journey and warrant the single-use bag’s intact arrival at its final destination, keeping its precious contents protected from biocontamination and other damages.