Safe and reliable end-to-end logistic solutions

Downloads

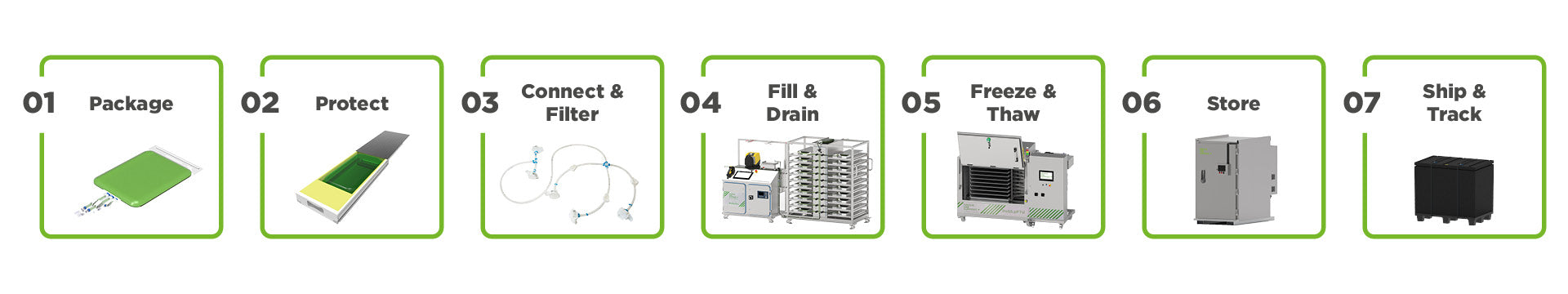

Solution overview: Bulk drug substances

Please fill out the form below to download this file.

Solution overview: Bulk drug substances

Solution Overview Small Volumes

Please fill out the form below to download this file.

Solution Overview Small Volumes