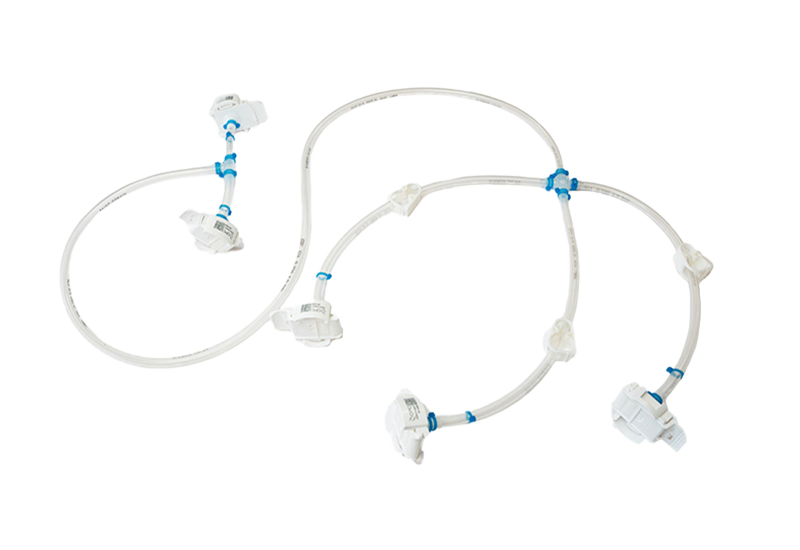

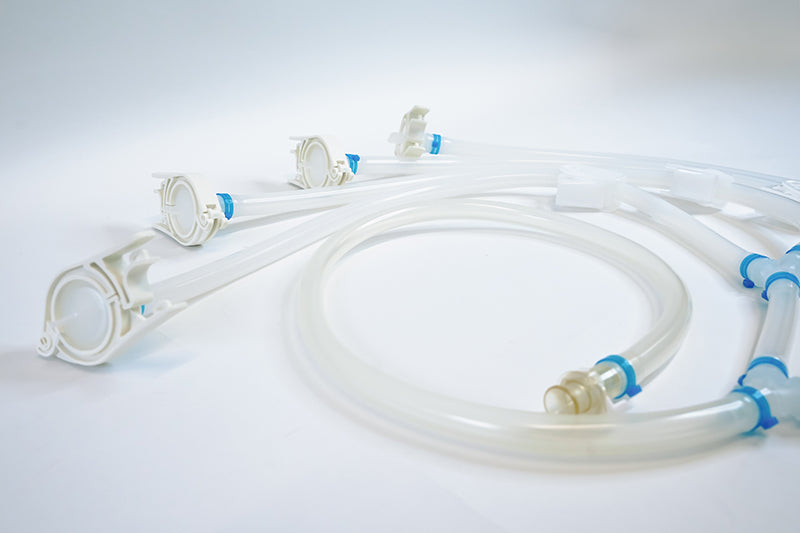

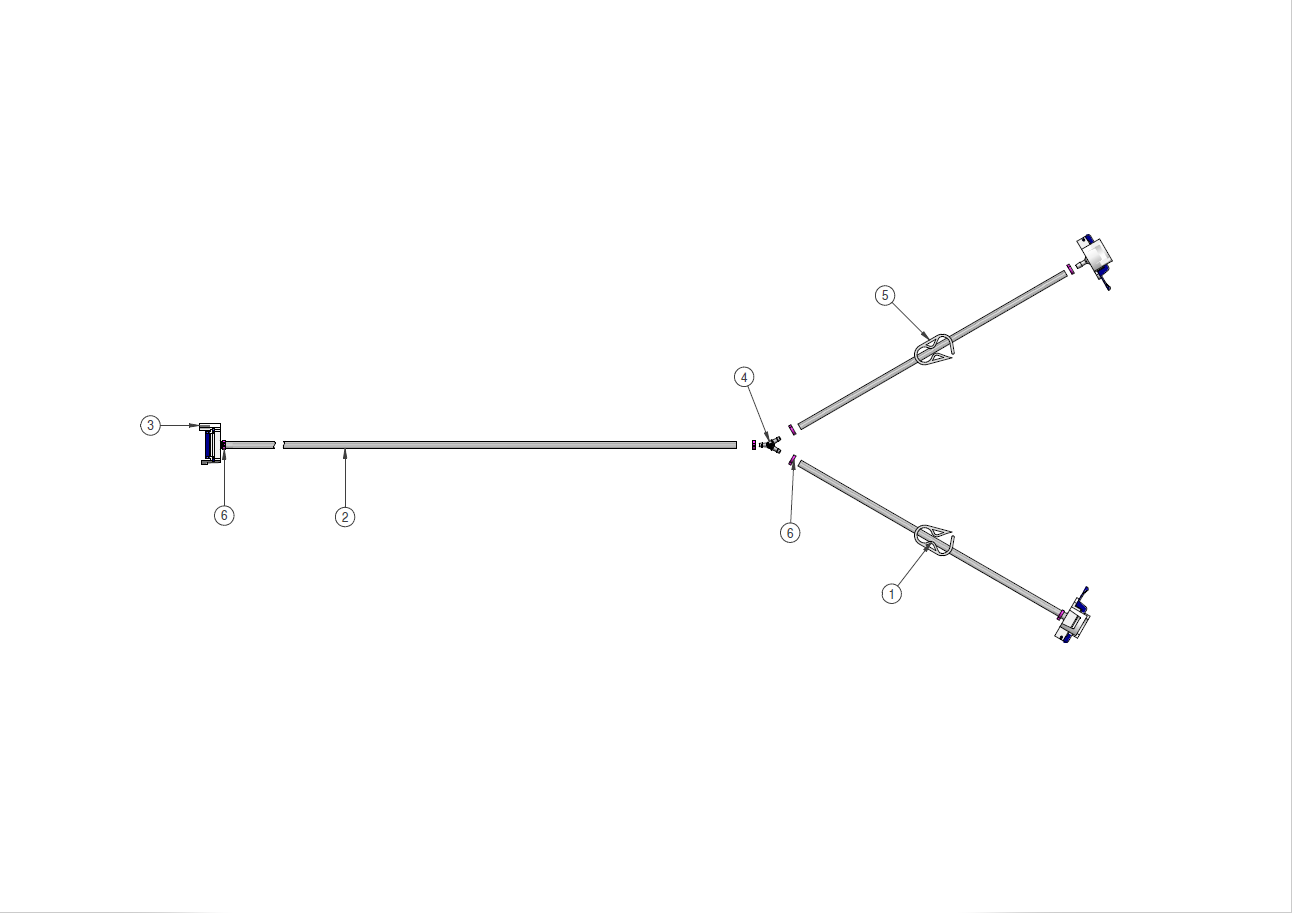

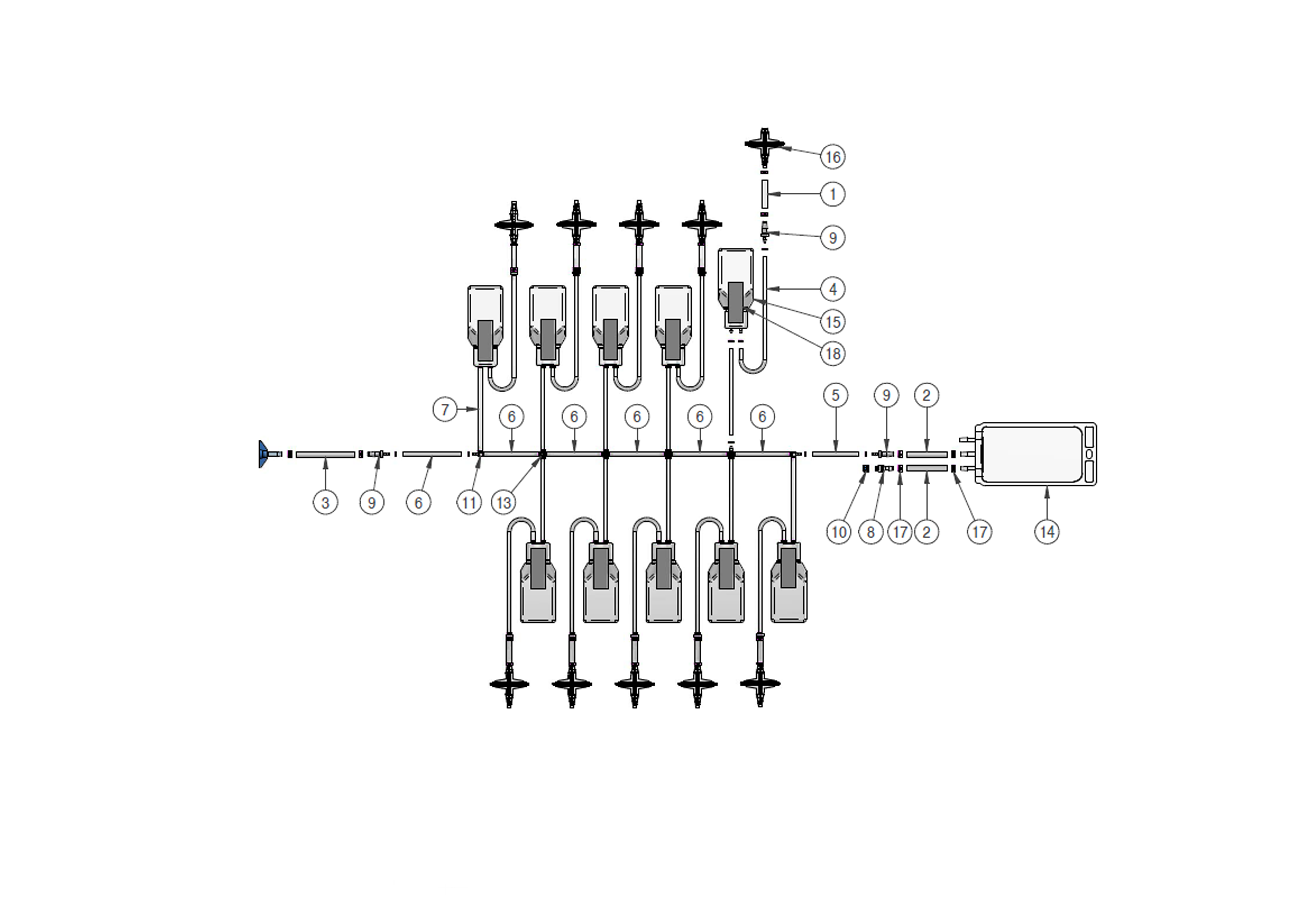

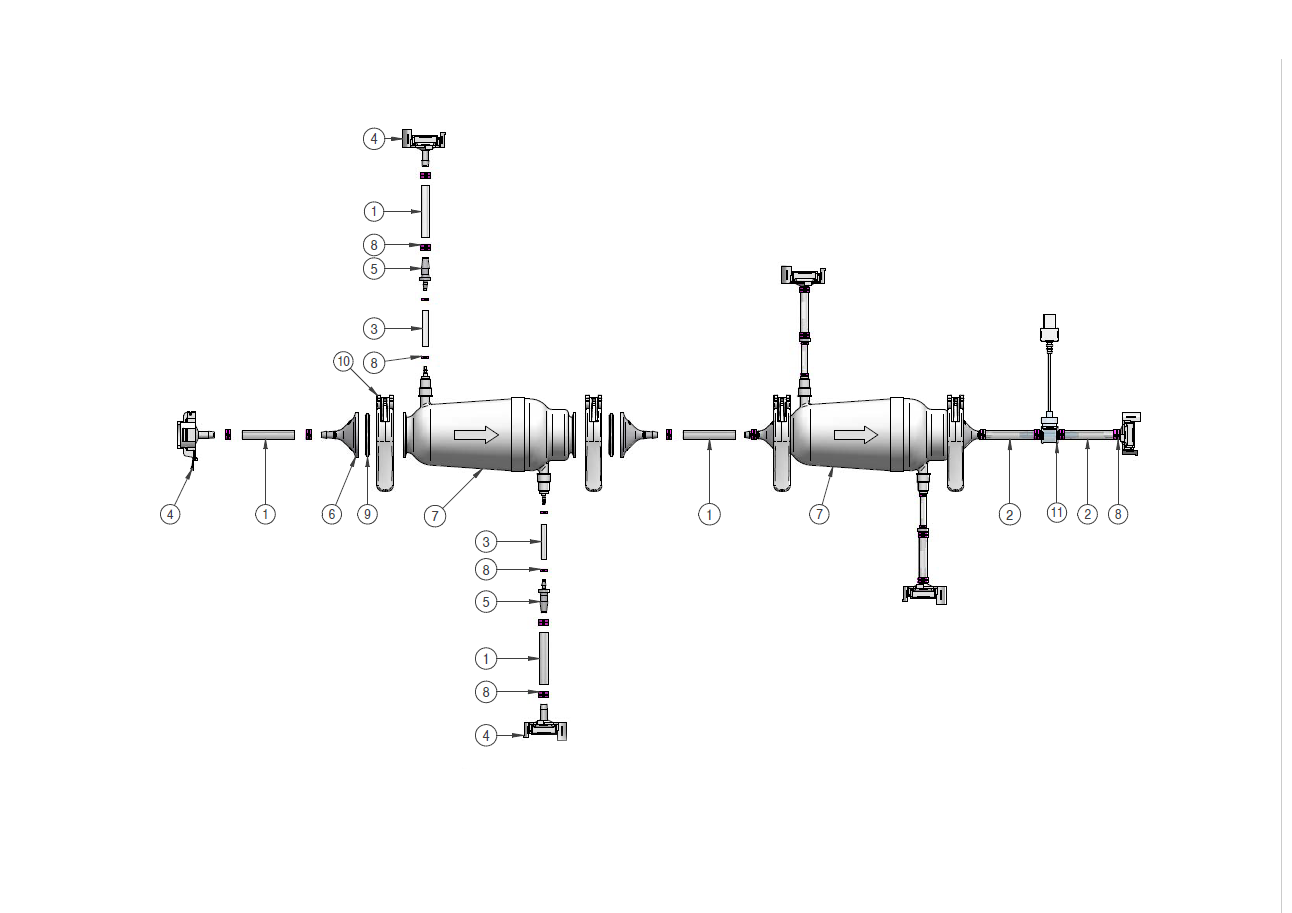

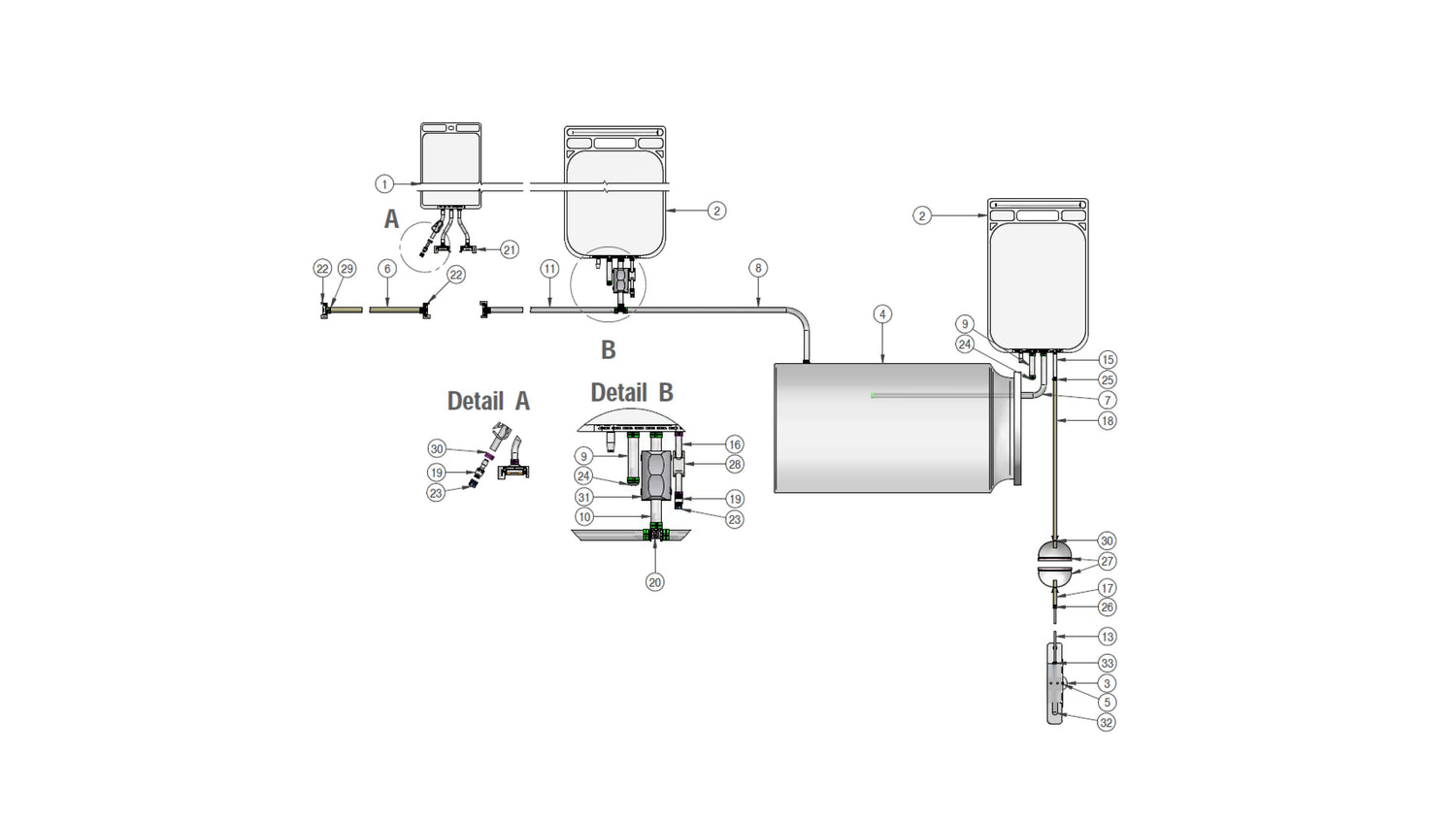

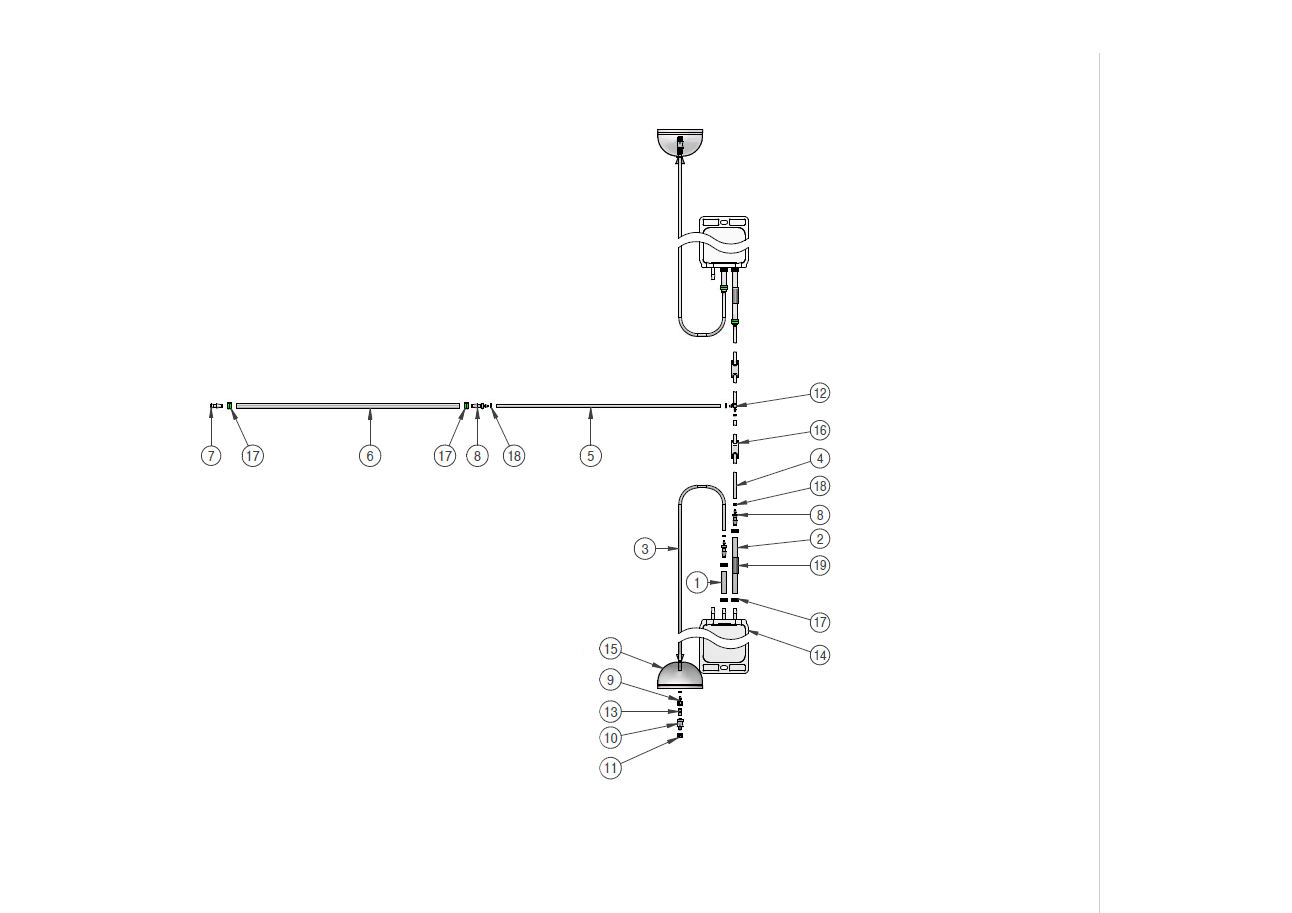

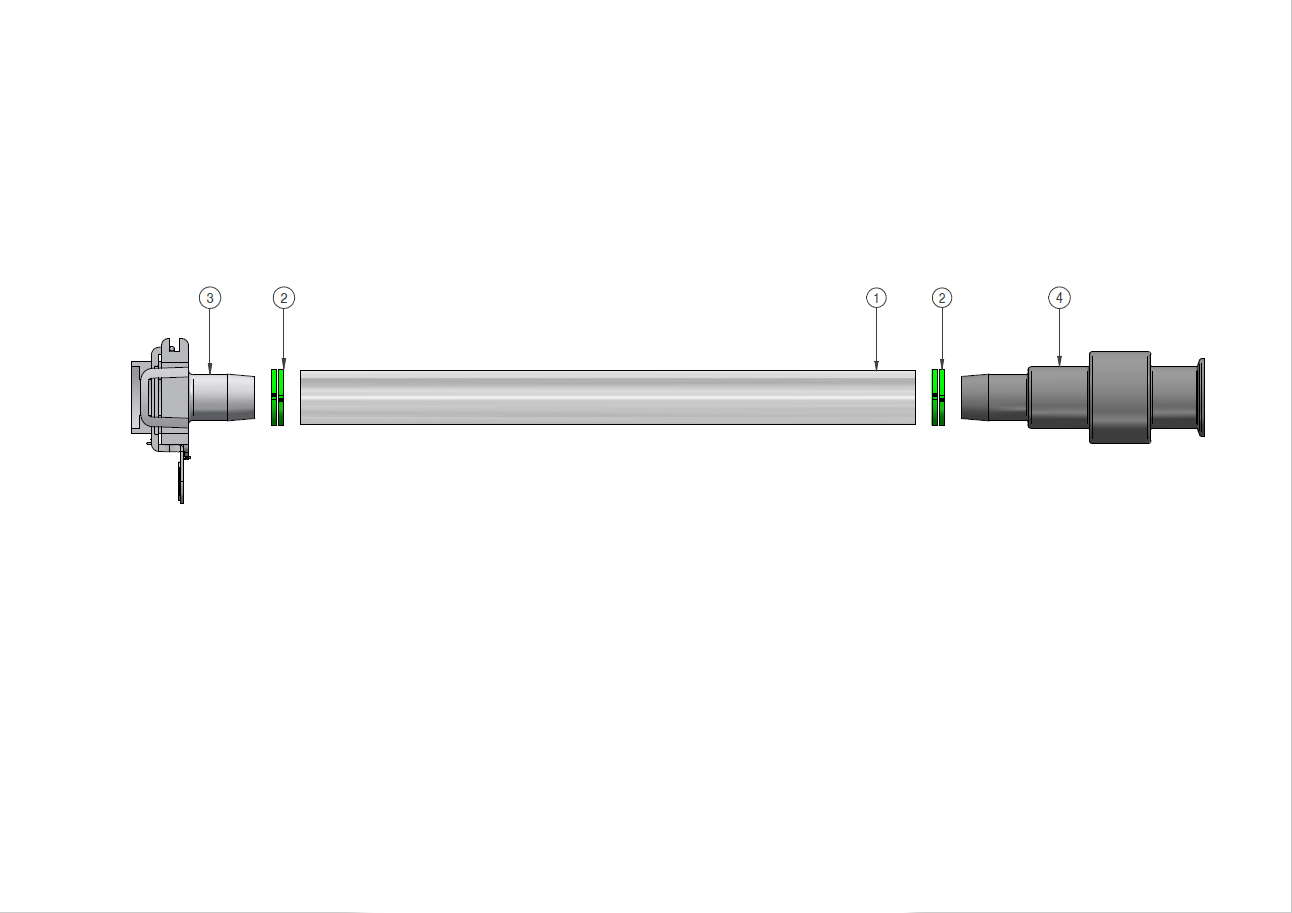

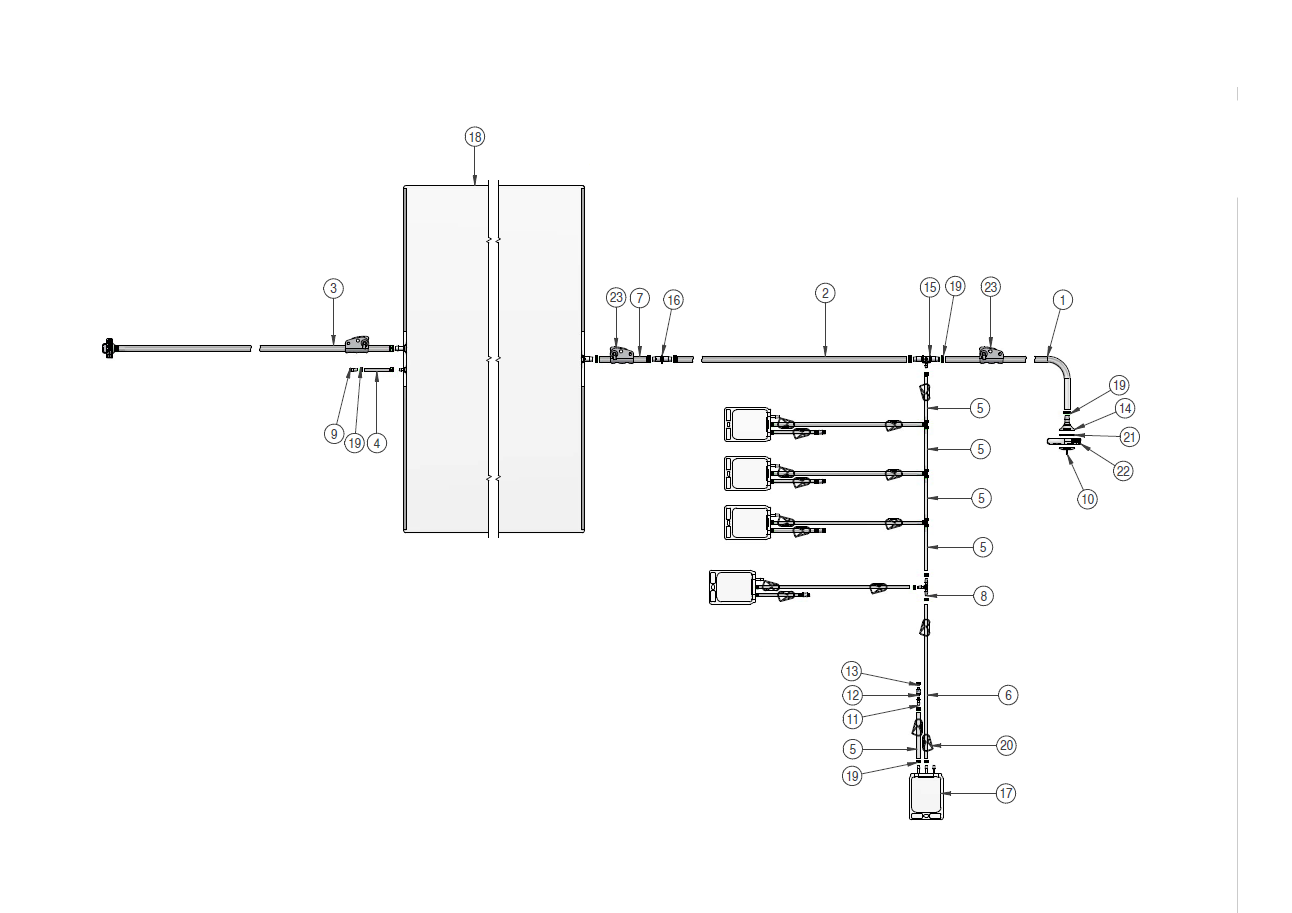

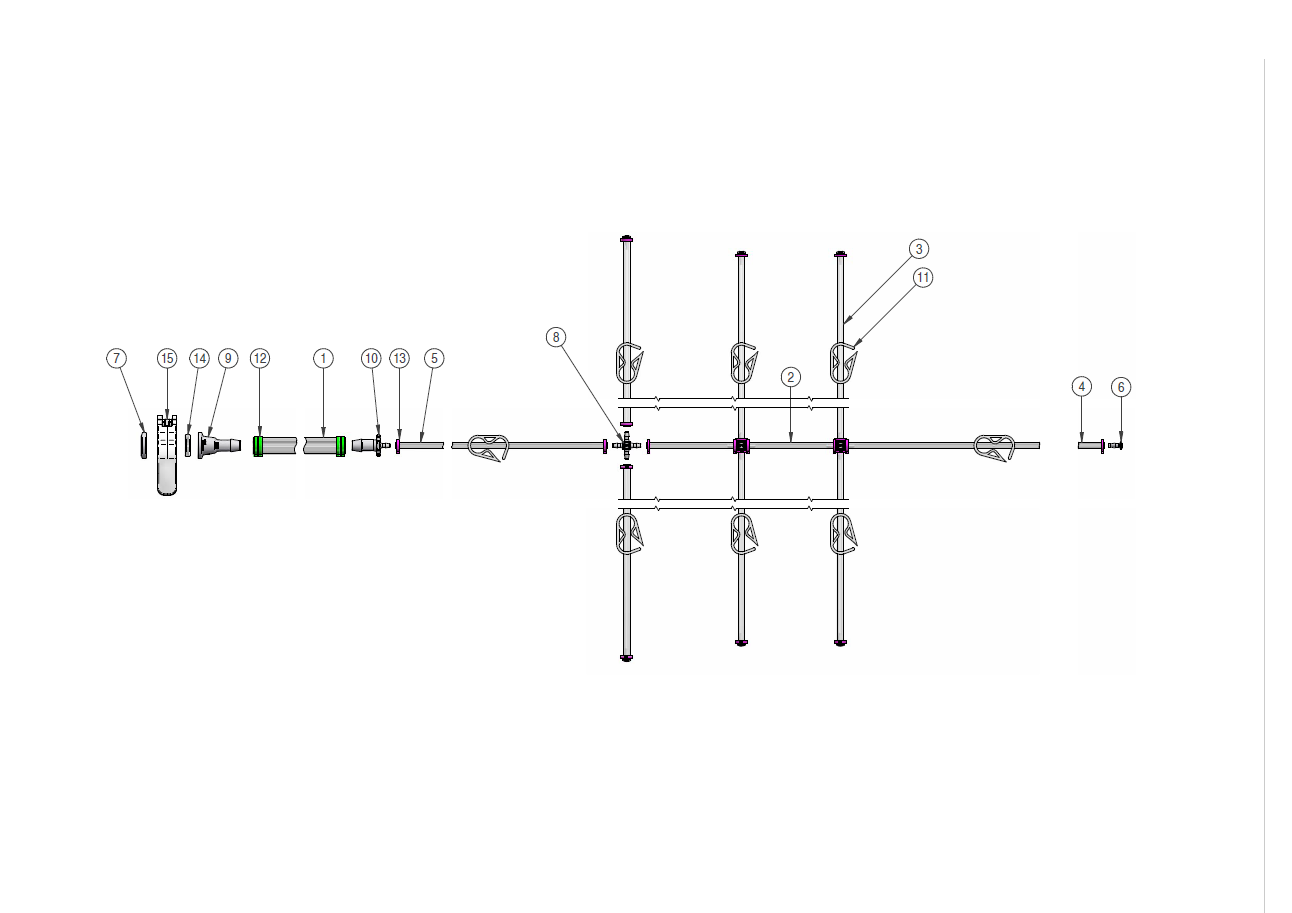

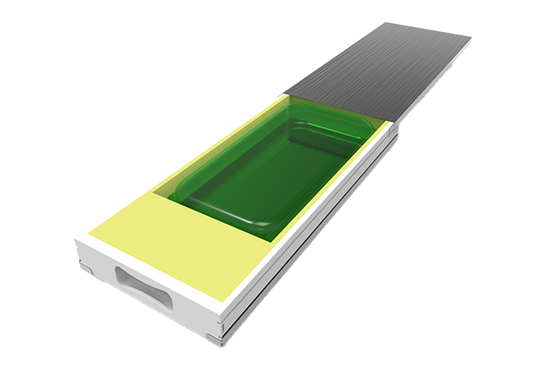

Components used for IRIS Single-Use Assemblies

Single-use assembly catalogue

Downloads

Datasheet: IRIS Single-Use Assemblies

Please fill out the form below to download this file.

Datasheet: IRIS Single-Use Assemblies

Case study: IRIS Single-Use Assemblies Capabilities

Please fill out the form below to download this file.

Case study: IRIS Single-Use Assemblies Capabilities

Whitepaper: IRIS Single-Use Assemblies - Connecting the dots

Please fill out the form below to download this file.

Whitepaper: IRIS Single-Use Assemblies - Connecting the dots