Downloads

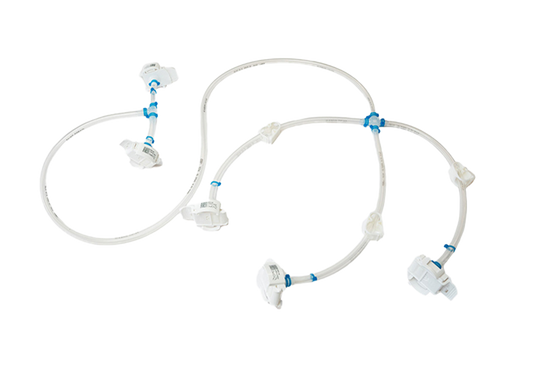

Datasheet: RoSS.FILL Bottle

Please fill out the form below to download this file.

Datasheet: RoSS.FILL Bottle

Case Study: Automating the process of filling media into bottles

Please fill out the form below to download this file.

Case Study: Automating the process of filling media into bottles