Download case study

Case study: RoSS.FILL - Forget about isolators

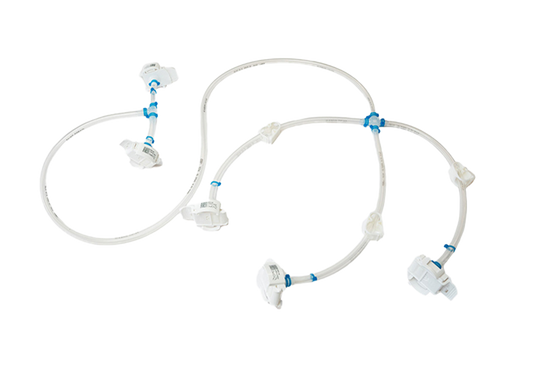

Advanced sealing pinch valves

GMP compliant to fulfill high standards in CGT production

Downloads

Datasheet: RoSS.FILL CGT

Please fill out the form below to download this file.

Datasheet: RoSS.FILL CGT

Whitepaper: RoSS.FILL - Automated aseptic filling

Please fill out the form below to download this file.

Whitepaper: RoSS.FILL - Automated aseptic filling