Aliquoting & freezing to optimize cell recovery

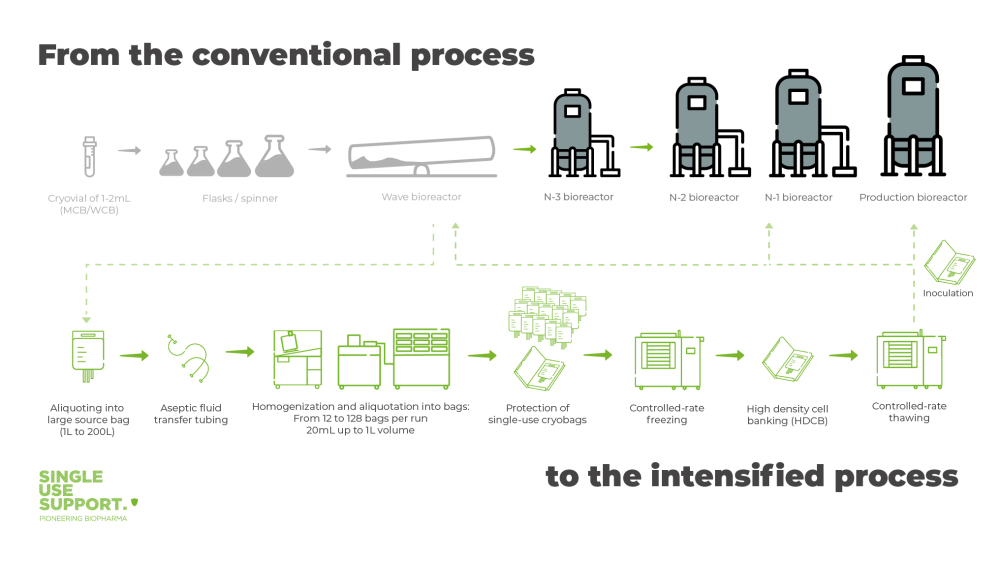

Single Use Support's end-to-end process solutions facilitate high density cell banking (HDCB) for seed train intensification. The high degree of automated process steps in cell aliquotation and cryopreservation help maximize cell viability, resulting in increased process efficiency and greater patient safety.