Case Study: Reducing product loss | Hybrid for primary packaging

Table of contents

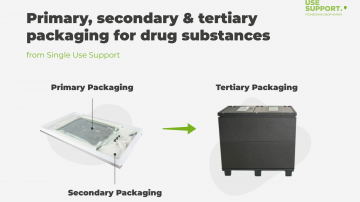

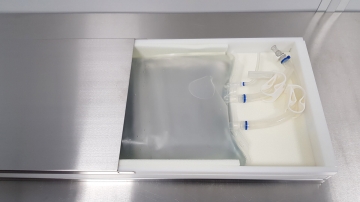

ShowCMO and CDMO are forced to collect a series of platform systems for biomanufacturing in different primary packagings: single-use bags, bottles and vials. The handling of different primary packagings results in a lack of standardized process solutions along with varying rates of product loss and inconsistent freezing behavior. To improve process inefficiency there is a need for hybrid platform solutions to cover fluid management for all primary packagings.

A CDMO, developing and manufacturing drug products for different customers, has decided to to implement a harmonized process solution that can be used with different types of single-use primary packaging whilst at the same time minimzing the rate of product loss.

This case study illustrates the advantages in terms of cost-efficiency and reduced workforce through hybrid systems for protective single-use shell solutions around liquid transfers in biopharmaceutical manufacturing.