Primary and secondary packaging of drug substances

Table of contents

ShowThroughout the manufacturing process of drug substances, the liquids must be transferred frequently, such as during the upstream and downstream processing. Safe packaging of large volume substances is of high necessity in each step. Protection is ensured by appropriate primary and secondary packaging.

This article will provide an overview of the different types of primary and secondary packaging materials, which are used specifically for safe handling of drug substance. It will also cover the characteristics of single-use consumables as solutions for biopharmaceutical packaging.

What is primary and secondary packaging in the pharmaceutical industry?

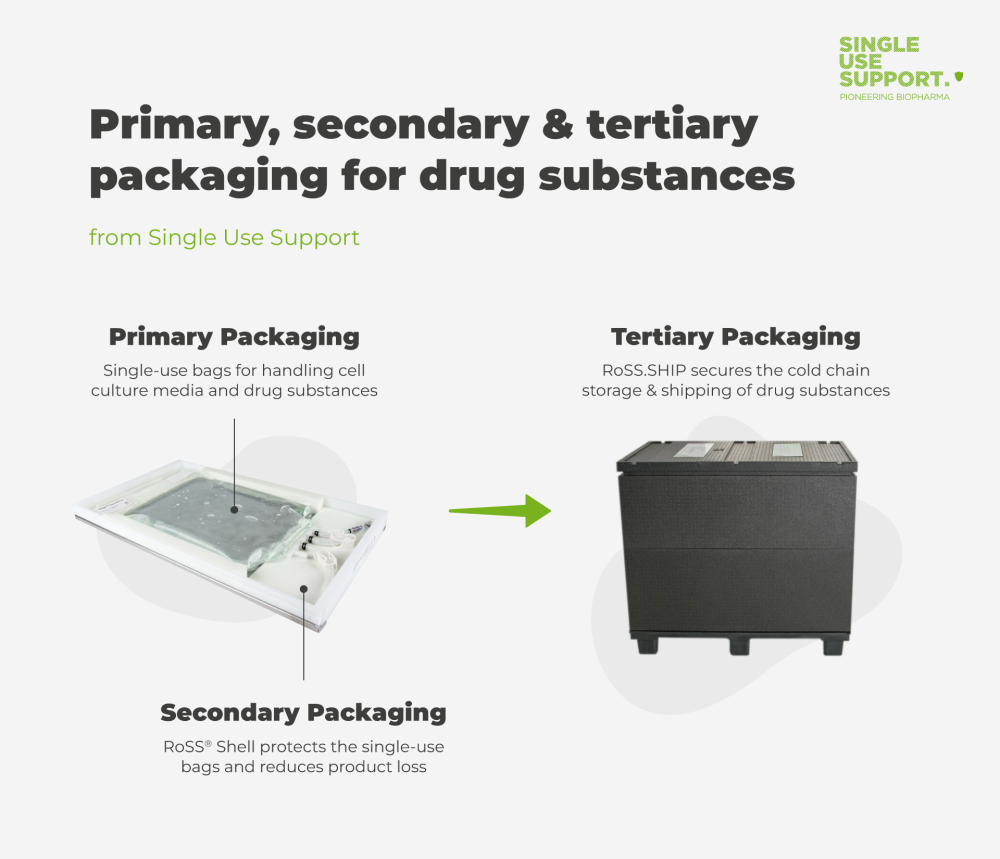

The primary packaging is the packaging that comes into direct contact with the pharmaceutical products. A secondary packaging is the outer packaging, which provides extra protection to the primary packaging during storage and transportation to reduce the risk of breakages of the primary packaging.

Additionally, a tertiary packaging refers to another layer of packaging used to transport and store large quantities of secondary packaging in an efficient manner.

In the specific case of drug substance management, safety is the most important aspect. Primary packaging and secondary packaging complement each other in their protective effect, and are thus both essential parts responsible for the protection during transportation between the different stages in the upstream and downstream process.

It is important to ensure that both types of packaging are designed and produced to the highest standards to guarantee the safety and effectiveness of pharmaceutical liquids.

Primary packaging for biopharmaceuticals

Biopharmaceuticals are complex molecules that require specialized primary packaging to maintain their stability, sterility, and potency. Some challenges and risks associated with primary packaging for biopharmaceuticals include contamination, product degradation, and theft.

Types of primary packaging

A primary packaging is an essential part of the logistics of pharmaceuticals as it helps to ensure the safety, efficacy, shelf life and quality of drugs. The choice of packaging material and type is dependent on the form and chemical composition of the drug. Pharmaceutical products are packed in different types of primary packaging. Here you can find an overview of primary packaging:

- tablets: blister packs and blister packaging

- liquids (during manufacturing): vials, ampules, bioprocess containers, bottles

- liquids (after fill/finish): vials, syringes, dropper, sachet packaging, pouches

A variety of materials is used for primary packaging, including glass, plastic, and metal. Glass containers are frequently used because they are chemically inert, while plastic bottles and plastic containers are popular for their flexibility, lightweight, and affordability. Metals, such as steel, aluminum, and tin-plated steel, are primarily used for packing gel forms, due to their low reactivity.

The fact that plastics like PVC have lower inertness and permeability to vapor and gas, which can result in contamination or product degradation, is not true. Innovative single-use technology based on plastics offers equally safe storage with many advantages.

Primary packaging from Single Use Support

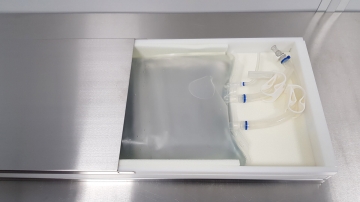

Bioprocess containers are a crucial type of primary product packaging used in the pharmaceutical industry. They are cost-effective and used to contain high valuable drug substance for safe frozen storage and shipping.

Bioprocess containers are out of different types of materials. Types of plastic are differentiated by their elasticity and can be multilayer or simple layer films.

The main distinction is between these 3 types of materials:

- EVA (ethylene vinyl acetate copolymer)

- Fluoropolymer

- PE (Polyethylene)

IRIS single-use bags are made of a PE multilayer film, but also other bag types are available by Single Use Support.

Single-use bioprocess containers, also known as single-use bags, are increasingly being used in the biopharmaceutical industry for the handling of drug substances in every volume. Single Use Support is a leading expert in single-use systems and offers custom packaging solutions to meet the unique needs of clients in the pharmaceutical industry.

IRIS Single-Use Assemblies

Whitepaper: Connecting the Dots

Creation of Single-Use Assemblies for Pharmaceutical Fluid Management

Secondary packaging for biopharmaceuticals

The secondary packaging perfectly complements the internal primary packaging for maximum protection. It provides physical protection and barrier protection and often needs to guarantee regulatory compliance. All this in order to be able to transport the drug substances safely or to bring the final products to the patient.

Examples of secondary packaging include shells as a safe protection but also folding cartons, paperboard, trays, and film bundles. Secondary packaging can, but does not have to, play its role as the first packaging layer that consumers will see. In some cases, there is a tertiary packing, too.

It provides protection to the primary packages and products during distribution, display, and branding. It creates a separation that protects primary packaging components from one another and prevents products from mobilization during shipment.

Secondary packaging also plays a direct role in protecting the product and primary package from mistreatment or accidents by consumers. In addition, it provides ample space for branding, artwork, and regulatory information that is essential for product display and adherence to regulations.

Secondary packaging from Single Use Support

Single-use shells are a type of secondary packaging that addresses packaging needs and packaging design. Single Use Support is a leading packaging company and provider of single-use shells, with their high quality RoSS® Shell being the first product they launched.

The RoSS shell offers 100% protection for the single-use bags it contains, and it is suitable for all possible volumes between milliliters in the cell and gene area and 50-liter bags of bulk drug substance. The shells are made from a highly durable and flexible material that provides excellent protection for the bags during freeze and thaw processes.

Single Use Support’s RoSS shell is not only designed to provide protection, but also enables advanced plate-based freezing technologies. The almost direct contact between the freezing plate and the bag makes controlled fast freezing possible.

Pharmaceutical packaging is crucial to ensure their safe storage and shipping. Biologics have specific regulatory requirements, defined by FDA, EMA, and ASTM D4169 for storage and transportation, starting with the correct packaging to enable efficient filling, freezing, and transportation.

Single Use Support offers end-to-end solutions to its customers in the biopharma industry, including fully automated platforms for filling and freezing, as well as consumables such as single-use bags, shells, and shippers for safe storing and shipping. With these solutions, biopharmaceutical products can be transported and stored safely and tamper-evident, while maintaining their quality and integrity.

Packaging of Biopharmaceuticals for safe storage and shipping

Pharmaceutical packaging is crucial to ensure their safe storage and shipping. Biologics have specific regulatory requirements, defined by FDA, EMA, and ASTM D4169 for storage and transportation, starting with the correct packaging to enable efficient filling, freezing, and transportation.

Single Use Support offers end-to-end solutions to its customers in the biopharma industry, including fully automated platforms for filling and freezing, as well as consumables such as single-use bags, shells, and shippers for safe storing and shipping. With these solutions, biopharmaceutical products can be transported and stored safely and tamper-evident, while maintaining their quality and integrity.1

- Increasing Biopharmaceutical Quality Through Packaging Partnerships, https://bioprocessintl.com/manufacturing/fill-finish/increasing-biopharmaceutical-quality-through-packaging-partnerships-303901/, Published 01.10.2010