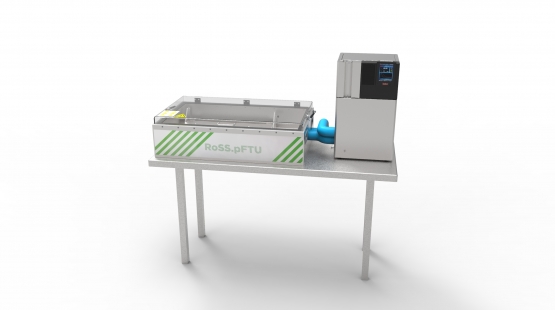

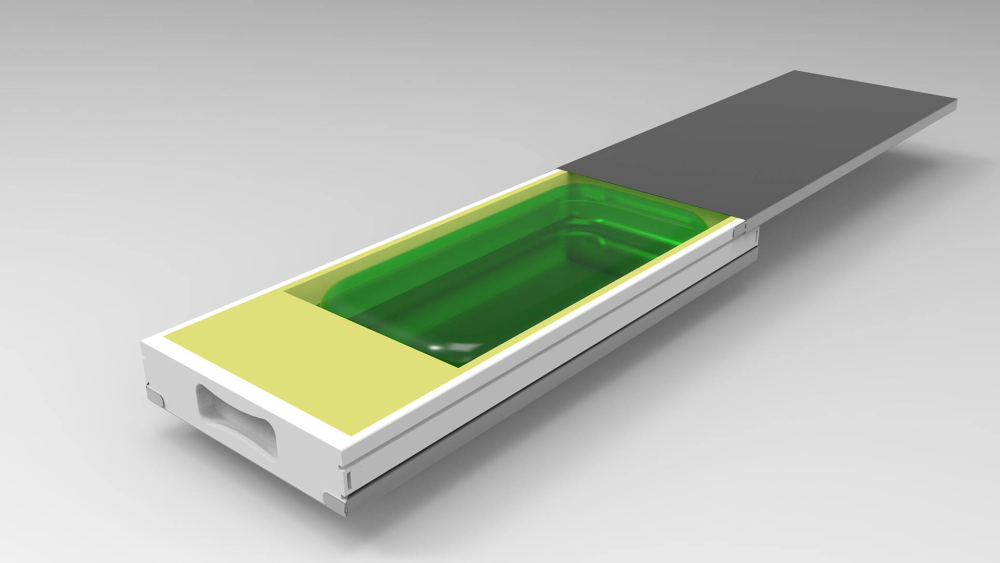

Our plate-based laboratory freezer (lab scale) is the perfect solution for clinical studies conducted in labs and, above all, if you want to start a controlled, cGMP-compliant and scalable freezing & thawing process.

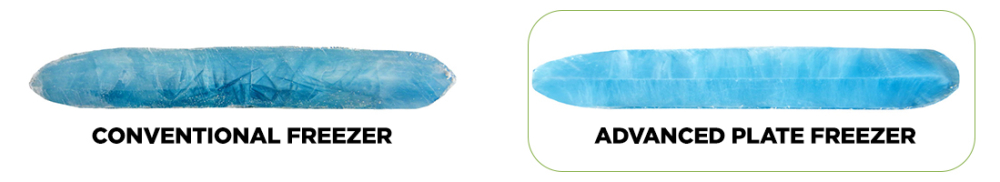

This lab freezer shows the best product stability results for Cell and Gene therapy or mAbs. RoSS.pFTU Lab-Scale is compatible with single-use bioprocess containers of all sizes and manufacturers.