Safe handling of monoclonal antibodies: Best practices

Table of contents

ShowHandling monoclonal antibodies safely can be quite a challenge for biopharmaceutical manufacturers. mAb production is a sensitive process, prone to contamination risks that can easily lead to product alterations and product loss.1 To protect staff and patients from severe consequences, it is therefore necessary to meticulously follow manufacturing regulations all along the monoclonal antibody production process. The right equipment and technological solutions can help to streamline the manufacturing process, increase product safety, and improve time and cost efficiency.

In the following, we take a closer look at the risk of monoclonal antibodies, how staff and patients can be protected, as well as innovative solutions that help manufacturers master these challenges.1

Monoclonal antibody handling – who is at risk of what?

The limited research on the handling of mAbs provides no evidence that mAbs should be considered a health risk to medical personnel. However, monoclonal antibody drugs often require special handling.2 The safety risk for staff in handling monoclonal antibody conjugations arises from components like cytotoxic agents or radioisotopes. Direct exposure of operating staff during manufacturing processes can evidentially lead to chromosomal abnormalities, cancer, or severe skin irritation.3

Advanced therapeutics like ADCs are composed of monoclonal antibodies and a cytotoxic payload. And while there is a considerable amount of research on the risks of conjugation agents available, there is a lack of conclusive studies on the handling of mAbs. As a consequence, there is no universal code of conduct for medical staff when handling mAbs, yet.

Concerns are that frequent exposure via dermal, inhalation, and mucosal absorption of mAbs in manufacturing companies can lead to immunogenicity, toxicity, cytotoxicity or carcinogenicity, which is why safety measures are advised. These range from basic precautions like wearing a gown and covering eyes, nose and mouth while handling mAbs to the use of closed-system-drug-transfer-devices (CSTDs).4 5

CSTDs prevent drug substances from being exposed to the environment and show a substantially lower risk of leakage than common transport devices.6 They come with features that not only safeguard the safety and health of medical staff when administering the drug as well as during production, but can also guarantee increased product safety because the drugs maintain sterility.2 3 4 5 6

Regulations concerning mAb handling

In order to guarantee a drug product that is safe to use for patients, there are specific regulations concerning mAb handling during manufacturing of pharmaceutical products. Regulations for mAb production may vary slightly between regions, but they all follow guidelines set by the World Health Organization (WHO).7

- During mAb production, manufacturers are obliged to document the different steps as well as starting materials meticulously.

- Further, the WHO established rules to minimize the risk for contamination through microbes through sterilization of production materials and equipment. Staff is advised to perform tests on container safety regularly, such as PUPSIT (pre-use post sterilization integrity testing), as well as on batch integrity.8 9

To comply with all the regulations and maintain aseptic handling throughout the manufacturing process can be a challenge that is only to be addressed with innovative technological solutions that are highly adaptable and flexible.

7 7 9

Best practices for critical mAb production steps – with RoSS® Shell

There are several process steps in mAb production that require an increased amount of precaution. One of the biggest challenges in mAb production is product loss because of errors during handling, and contamination risks through leakage, exposure to hazardous intermediates, and improper handling during transportation.

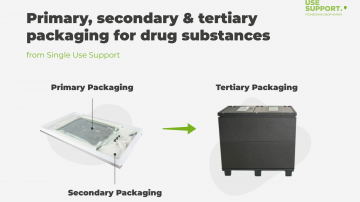

Challenges like maintaining the cold chain call for innovative protection devices for mAbs during storage and transport. This is why Single Use Support has developed the RoSS® Shell. This protective secondary packaging was designed to keep drug substances and starting fluids in single-use bags safe from damages during handling. The protective shell is stackable to save space during storage, and enables improved freezing and thawing mechanisms.

Closed end-to-end processes – a holistic approach

Closed end-to-end processes are very efficient in reducing costs in mAb production, as they minimize contamination risks as well as product loss. Every step of the production is compatible and carried out in one closed platform, which means that substances are protected from exposure during filling and dispensing, as well as freezing and thawing.

Flexibility and adjustability to changing manufacturing requirements are one of the most important trends in monoclonal antibody production. The purpose of end-to-end processes is to make it easier for producers to react to the industry’s demands and, in consequence, significantly reduce costs in mAb production. 10

Safe filling of monoclonal antibodies

Biologics must be produced aseptically and sterilized by filtration to guarantee product safety for patients, which is why aseptic filling of mAbs is of utter importance. If mAbs are exposed to contamination during filling in transport containers, vials or bags, this results in product loss of a full production batch.

To minimize these risks and make the process of mAb production more consistent and reliable, Single Use Support has developed RoSS.FILL – an automated aseptic filling platform. This fully automated drug dispensing system is highly flexible in terms of production volume (scale-up) and number of bags or bottles (scale-out).11

Freezing process in mAb manufacturing

The freezing process in mAb production is a crucial procedure to preserve antibodies and keep them accessible. It allows the safe storage and transport of monoclonal antibodies over extended periods of time. However, intricacies include designing a process that meets the freezing behavior of monoclonal antibodies. This calls for high control over freezing rates, as well as safe packaging of single-use bioprocess container

Singe Use Support offers RoSS.pFTU – a freeze/thaw platform based on plate freezing that allows high customization of freezing processes. The enhanced control over cooling and thawing rates, combined with the bag’s protection provided by RoSS® Shell, makes this plate freezing platform ideal to prepare mAbs for cold chain storage and transport.

Download Guide

Navigating 5 Overlooked Challenges in Monoclonal Antibody Manufacturing

mAb storage and transport

After mastering the critical freezing step for mAbs, they are typically stored for future use or transported to the next production facility. Especially in large productions, monoclonal antibody storage solutions need to be efficient and save space while also being able to maintain the cold chain.

For this reason, Single Use Support has designed the ultra-low temperature freezer RoSS.ULTF, where mAbs can be efficiently stored at temperatures as low as -75 °C. Real-time temperature control and high storage density are main assets of this device, powered by the modular interior that can provide space for primary packaging in various sizes.

In addition, the RoSS.SHIP container is designed to facilitate mAb transportation, able to hold the cold chain for almost one week. Both can be efficiently filled with RoSS® Shell protection containers for single-use bags, for maximized space efficiency and process safety.

Read more: Monoclonal antibody storage

Partnering with Single Use Support in safe mAb handling

With mAb production being one of the fastest growing sectors in the pharmaceutical industry, there is a great demand for new solutions for monoclonal antibody development and manufacturing. Single Use Support aims to provide cost- and time-efficient solutions for companies that manufacture mAbs and help them face their production challenges.12

End-to-end technologies for bioprocessing fluid management help to make mAb production more efficient. RoSS.FILL, in combination with highly adaptable and flexible equipment, ranging from single-use bags to RoSS® Shell, minimize the risk for human errors and product loss.

While transport can become a burden due to mAbs’ sensitivity to temperature changes, the combination of Single Use Support’s plate freezer RoSS.ULTF, RoSS® Shell, and the protective transportation system RoSS.SHIP makes sure that the cold chain can be maintained.12

Further articles about safe mAb manufacturing

- Viral contamination of monoclonal antibody preparations: Potential problems and possible solutions, https://link.springer.com/content/pdf/10.1007/BF00148806.pdf, Published 1990

- Safe handling and administration of MABS: the guidance, http://dx.doi.org/10.12968/bjon.2015.24.sup16a.s14, Published 2016-06-11

- Challenges of Using Closed System Transfer Devices With Biological Drug Products: An Industry Perspective, http://dx.doi.org/10.1016/j.xphs.2019.10.042, Published 2019-11-04

- Frequency and component analysis of contaminants generated in preparation of anticancer agents using closed system drug transfer devices (CSTDs), http://dx.doi.org/10.1038/s41598-021-03780-0, Published 2022-01-07

- Understanding Closed-System Transfer Devices: Why They Are Important and How to Select an Appropriate System, https://www.pharmacytimes.com/view/understanding-closed-system-transfer-devices-why-they-are-important-and-how-to-select-an-appropriate-system, Published 2016

- Position Statement on safe handling of monoclonal antibody drugs, https://clearvoice-media.s3.amazonaws.com/act_bIfy6fAJQzK1gLfS/reference-materials/1619015740026-2020-08-03PositionStatement-SafeHandlingofMonoclonalAntibodydrugs2.pdf, Published 2020

- Current GMP standards for the production of vaccines and antibodies: An overview, http://dx.doi.org/10.3389/fpubh.2022.1021905, Published 2022-11-03

- Current GMP standards for the production of vaccines and antibodies: An overview, http://dx.doi.org/10.3389/fpubh.2022.1021905, Published 2022-11-03

- Guidelines for the production and quality control of monoclonal antibodies and related products intended for medicinal use, https://cdn.who.int/media/docs/default-source/biologicals/final-who-guidelines-on-mab-production-and-quality-control-annex-4---7-jun-2022.pdf?sfvrsn=8c542f00_1&download=true, Published 2022

- End‐to‐end continuous bioprocessing: Impact on facility design, cost of goods, and cost of development for monoclonal antibodies, http://dx.doi.org/10.1002/bit.27774, Published 2021-04-01

- Aseptic Vial Filling, http://dx.doi.org/10.1385/1-59259-076-4:313, Published 2003-11-15

- A Look At The Growing Market Landscape For Monoclonal Antibodies, https://www.bioprocessonline.com/doc/a-look-at-the-growing-market-landscape-for-monoclonal-antibodies-0001, Published 2023