Scaling mAb production: From lab to large-scale

Table of contents

ShowScaling up monoclonal antibody (mAb) production is the pressing challenge faced by many in biopharma today. The need to meet the surging demand for these crucial therapies drives an urgent search for practical, effective solutions.

In this article, we will discover when scalability is best considered, establishing mAb production processes. Furthermore, we will illustrate factors that determine scalability and learn about innovative solutions that can accompany mAb manufacturers from lab to large-scale.

Why keep scalability in mind?

Considering scalability right from the start of monoclonal antibody production planning is crucial. It means factoring in the potential for future growth and expansion at the initial stages of designing production processes. This early consideration allows for the implementation of adaptable systems that can seamlessly accommodate increased demands as production moves from research to large-scale manufacturing.

The need for scalability in mAb production is due to the rising request for these products across various medical fields. The increasing use and effectiveness of monoclonal antibodies have led to a surge in demand, necessitating efficient and scalable production processes.

But also preparing for the future landscape of healthcare is essential, where mAbs are expected to play an even more significant role. In fact, the global monoclonal antibody market was projected to have a compound annual growth rate (CAGR) of more than 11% between 2023 and 2030.1 Thus, integrating scalability is a strategic move that aligns production capabilities with the changing requirements of the healthcare industry.1

5 Factors that determine scalability in monoclonal antibody production

Scalability in monoclonal antibody production hinges on several critical factors that have great impact on the ability to expand production with the aim of meeting increasing demands.

1. Cell line development

Selecting scalable cell lines is a critical step when designing efficient monoclonal antibodies at every scale, and it is often not possible to easily change expression platforms without further ado.

Through genetic engineering and optimization processes, cell lines like mammalian cells can be tailored for high yield and stability, ensuring a seamless transition from lab-scale to large-scale production.

2. Necessary vs. available resources?

Scale-up in biopharmaceutical manufacturing is often a question of balancing the necessary and the available resources. Ensuring alignment between raw materials, equipment, and workforce capacity with the demands of increased production is essential for scalability. This involves assessing current resources, identifying gaps, and strategizing to bridge them – all of which efficiently without compromising quality or timelines.

No matter the scale – efficiency is key. Limiting factors like space capacities have to be taken into consideration, as well as the necessary human resources. After all, production costs of monoclonal antibodies have to be kept as low as possible in order to make anyhow elaborate and thus expensive mAb therapies more accessible.

3. Flexible solutions for more than one production line

In scaling up monoclonal antibody production, flexibility is paramount when managing different production lines. This adaptability becomes crucial due to the diverse requirements of various mAb products and production scales, as well as ongoing trends in mAb production. Implementing adaptable systems allows for seamless operations across these distinct lines, optimizing resources and bolstering overall efficiency.

Different mAb variants and products often necessitate unique processes or conditions. Flexibility enables swift adjustments without disrupting ongoing production, accommodating changes in product specifications or demand fluctuations.

Moreover, the ability to swiftly adapt to emerging needs or technological advancements is essential. This is even more important for CDMOs (Contract Development and Manufacturing Organizations), as they frequently have to cope with changes when working with different partners or on multiple production lines.

4. Reliability, consistency, and compliance

Reliability in mAb production is vital at every scale, necessitating robust systems that minimize downtime and ensure safe handling of monoclonal antibodies. When producing monoclonal antibodies or related drugs, minute volumes have to be handled, with no room for deviations. Procedures that have proven to be successful in lab-scale manufacturing, however, are often not suitable for scaling up – either because they forfeit precision or due to lacking efficiency.

Consistency might become another constricting factor in scaled-up mAb production. Consequently, standardized procedures and stringent quality checks guarantee that each mAb batch meets high-quality standards, whether produced in smaller test runs or larger industrial settings.

These standards – sublimated in regulations like cGMP – are to be complied with, regardless of production scale. But as already stated, not all processes and systems will allow mAb manufacturers to do so. This makes it favorable to check cross-scale compliance before implementing new machines or procedures.

5. Interoperability of implemented systems

When designing mAb production lines, many manufacturers prefer opting for end-to-end solutions provided by one specific brand. In fact, this often brings advantages like streamlined processes, with recurring elements for ease of use, and a fixed contact partner. But while these benefits are quite compelling, it is always good to have a choice.

Being limited to one single provider due to a lack of compatibility might become a major downside. This can, for instance, be the case when existing equipment is to be integrated, or when the chosen provider does not offer a solution that conforms with requirements that might arise later on.

Interoperability ensures a smooth exchange of data, synchronization of processes, and effective coordination between various equipment and software elements and by different providers, and is hence a crucial consideration for future-proof decisions.

Download Guide

Navigating 5 Overlooked Challenges in Monoclonal Antibody Manufacturing

Scaling up mAb production steps with Single Use Support

As an expert in biopharmaceutical process solutions, Single Use Support’s systems for fluid and cold chain management are designed to master the challenges of mAb production both at lab and large scale.

These solutions for monoclonal antibody production are valued for their non-negotiable precision and adaptability. However, the end-to-end processes they are framed by do not exclude components from other vendors. This vendor-agnostic approach makes Single Use Support’s product portfolio even more flexible, supporting mAb manufacturers in scaling various production steps of mAb production.

Aseptic fluid management

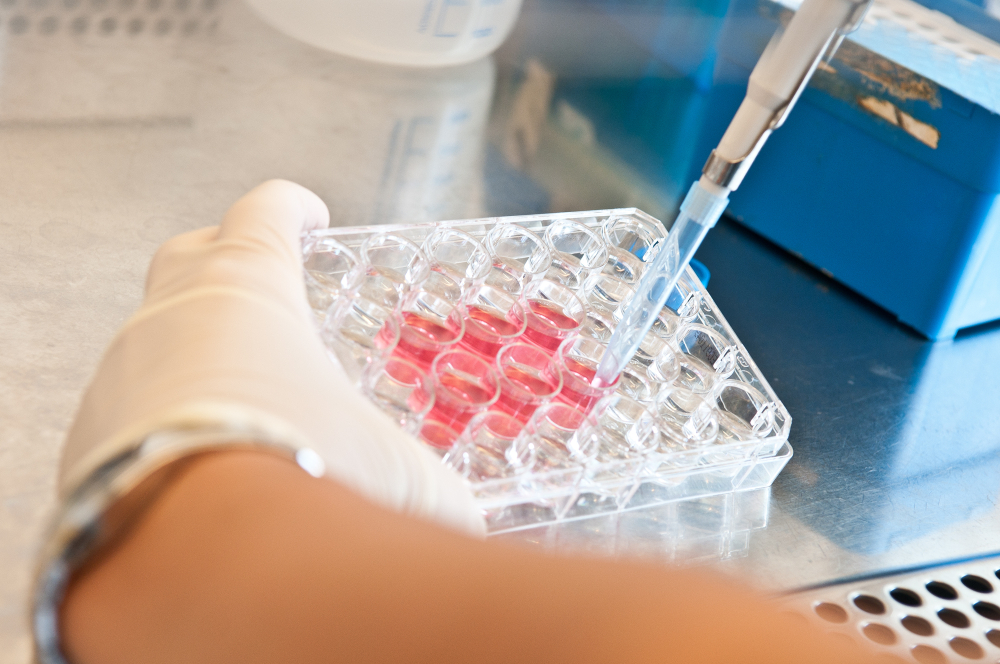

From cell banking and culturing to fluid transfer of reagents, intermediates, and final mAb products – maintaining aseptic conditions is crucial. But also the manufacturing suite is to be protected from sometimes hazardous compounds in mAb products – for instance the case with antibody drug conjugates (ADCs). Additionally, minute volumes have to be managed efficiently and with precision.

For this reason, Single Use Support has designed the aseptic filling platform RoSS.FILL. Its modular setup facilitates managing different volumes safely and effectively, with solutions for various production levels.

Read more: Aseptic filling solutions for monoclonal antibodies

Controlled-rate freezing

For long-term storage of monoclonal antibodies, the frozen state is preferred to preserve their efficacy and safety. Therefore, it is important to have effective solutions for antibody freezing and thawing available. However, even freezing larger volumes can be challenging.

Single Use Support’s freezing platform RoSS.pFTU rely on plate freezing technology. This advanced freezing method allows every representative of the freeze/thaw platform to achieve controlled freezing rates that can be adjusted to the requirements of different products.

Efficient storage and transport

Once frozen, monoclonal antibodies are ready for storage or shipping. Temperature-controlled monoclonal antibody storage, however, requires dedicated solutions that are not only reliable, but also space-efficient.

These are the major benefits of Single Use Support’s storage and transport solutions: They come with high storage density and customizable interior shelving systems while providing a safe environment for monoclonal antibodies waiting to be used.

- Monoclonal Antibodies Market Size, Share & Trends Analysis Report By Source Type (Chimeric, Murine, Humanized, Human), By Production Type (In Vivo, In Vitro), By Application, By End-use, By Region, And Segment Forecasts, 2023 - 2030, https://www.grandviewresearch.com/industry-analysis/monoclonal-antibodies-market, Published