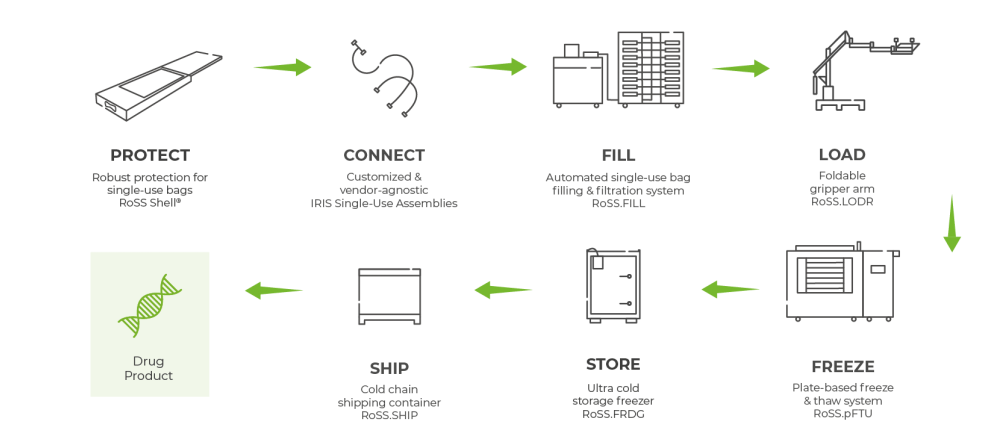

RoSS Technologies provide process flexibility for large volumes at highest quality.

- Closed, robust and tamper-evident protection of your single-use bag for highly valuable drug substances

- Vendor-agnostic and hence compatible to other systems during senstive freezing applications

- Process flexibility for safe handling regardless of type and size of bag manufacturer without being trapped in siloed biopharma process solutions