Why CDMOs are increasingly using single-use systems

Table of contents

ShowWhen it comes to the handling and processing of cell-based and biological drug substances, CDMOs (contract development and manufacturing organizations) are increasingly switching to single-use technology. There are several reasons for this shift, the advantages and disadvantages of which have been extensively discussed and debated for years.

As part of their fee-for-service activities, CDMOs typically operate several manufacturing lines. Manufacturing lines differ in scale and type of equipment - which forces the CDMOs to adopt systems that allow for flexible production capacities, fast changeovers, and rapid production at different scales.

By combining a number of benefits, single-use technologies that are compliant with cGMP and GAMP seem the perfect choice. For manufacturers of drug substances, they provide a more efficient, cost-effective, and scalable solution than stainless-steel tanks by offering:

- increased flexibility and faster set-up times

- reduced risk of contamination

- lower cleaning and maintenance costs

- easier scalability

- more efficient use of space

CDMOs as early adopters of single-use technologies (SUT)

Flexibility and scalability are great benefits with the use of Single-use compared to stainless steel technology applications. Apart from that, there are other reasons that explain why CDMOs are early adopters of single-use technology. CDMOs have to speed up biopharmaceutical processing of a fed-batch production and reduce process changeover times between different batches. Contract organizations are service providers and as such, if they want to be or remain successful, they have to keep up with the demands of the market if not be leaders in terms of new developments.

Both of these can be achieved with single-use systems, which offer flexible and more efficient alternatives to traditional multi-use equipment and processes. In addition to enabling manufacturers to respond quickly to changing market demands, they have the added benefit of reducing the risks of cross-contamination. This is vital when it comes to handling drug substances that are as sensitive as they are valuable.

Efficiency: Flexibility, scalability & high speed

Coming back to the biggest advantages of single-use technologies, how can SUTs take flexibility, scalability and high speed be taken to the next level?

Flexibility and scalability basically go hand in hand: Platforms consisting of single-use systems can be flexibly tailored to meet specific customer requirements, including the option to scale up or down quickly and easily, according to the volumes required. Modular systems enable flexibility, and automated systems coupled with state-of-the art process solutions enable limitles scalability. With single-use technology, it is possible to scale from 10mL to 400L per batch.

In addition, by enabling faster production processes and reducing lead times, they also increase the overall speed, be it in terms of speed to market, speed of reacting to changing requirements or changeover between processes.

Operating costs

While on the one hand disposable components equal ongoing costs caused by the recurring procurement of supplies, there are several factors that help reduce overall costs.

Amongst the main drivers of cost reduction are more rapid changeovers as well as a reduction in water and wastewater requirements and the elimination of both clean-in-place (CIP) and sterilize-in-place (SIP) validation. Along with an increased level of automation, this leads to a reduced need for labor - and energy - thus minimizing costs further.

According to an evaluation by the German biopharmacy and biotechnology company Rentschler, the annual costs of stainless steel are higher than those of disposable virus filtration systems in all but one category (Read the article in https://bioprocessintl.com). So generally speaking, it is advisable to consider the full life-cycle costs when contemplating a switch from traditional stainless-steel tanks to single-use technologies.

At Single Use Support, we have dedicated ourselves intensively to make total cost of ownership of automated single-use technologies transparent. Confirmed by several case studies based on real-world evidence, the evaluations confirm an early ROI of an investment in SUT. An important part is the reduction of OPEX (operational expenditures).

Reduction of operating costs go hand in hand with automated solutions:

- less labor

- less time-consuming processes (less resources)

- automated documentation thanks to 21 CFR Part 11 instead of manual documentation

What about sustainability and energy consumption?

It may sound paradoxical, but the reality is that disposable single-use components for biopharmaceutical manufacturing are in fact more sustainable than stainless steel. Traditional systems require high purity water and heat for cleaning and sterilization purposes, both of which have an impact on our environment. Single-use components, on the other hand, have a reduced need for cleaning and maintenance, which leads to a decreased consumption of water and energy.

This being said, disposal is still a consideration, not least because components might be classified as bio-hazardous. In addition, single-use systems are typically made up of different types of plastic materials that are difficult to separate. Using the mixed plastic waste for the production of durable products, such as pallets and plastic boards, could be a solution. This is just one approach to improve sustainability issues. Another idea is to develop sterile consumables that can be reused, such as the option of a multi-use protective shell for single-use bags. Single Use Support is developing in this area and provides the option of a multi-use protective RoSS(R) shell.

In addition, most suppliers of single-use components are striving to further reduce energy consumption. Single Use Support has been certified according to the EcoVadis Sustainability Rating 2022.

Why will many more CDMOs switch to single-use technology?

With SUT solutions constantly improving, there is an increasing number of reasons why CDMOs are or should be adopting single-use technology. From a production perspective, the most obvious benefit of single-use is time savings, with the potential of reducing setup time for each process from several days to mere hours. Flexibility and scalability offer great benefits and are important reasons why more and more CDMOs are moving to disposables.

The minimized need for cleaning and maintenance further reduces time spent while it also proves to be more environmentally friendly than traditional stainless steel equipment. Not to forget the safety and quality aspects that single-use systems offer. Closed systems reduce product loss and cross contamination.

Filling and freezing 1000L in less than 8 hours

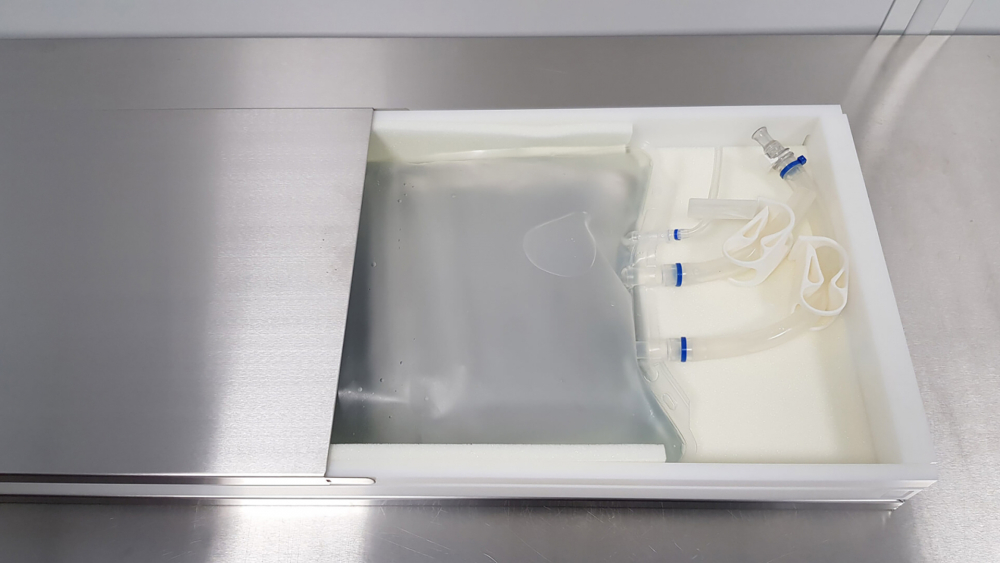

Providers of single-use technologies not only offer standalone products but also end-to-end processes that can be adapted to the requirements of each individual CDMO, allowing for the filling and freezing of up to 1,000 liters of drug substance in less than eight hours.

Automated processes help rule out human error, while allowing for the processing and handling of large volumes of drug substance in just a few hours. They cover the entire process including freezing and thawing, which makes them perfect for a number of applications in the biopharma industry, including, but not limited to, vaccines, mRNA, bioconjugates and monoclonal antibodies.