The safest transport solution for all available single-use bioprocess containers. Protect your single-use bag and reduce product loss towards 0%. RoSS®: Robust Storage & Shipping

The safest transport solution for all available single-use bioprocess containers. Protect your single-use bag and reduce product loss towards 0%. RoSS®: Robust Storage & Shipping

RoSS® stands for Robust Storage and Shipping. Our protective shell system is adapted from the oyster and has numerous advantages.

Due to a smart combination of materials, the single-use biocontainer has a 100% protective shell. The shells protect bags of any size and from any manufacturer. As closed tamper-evident system RoSS is stackable to increase storage density.

For particularly small volumes, such as in cell and gene therapy, RoSS.KSET is the perfect option.

RoSS® shells are available for all established single-use bag manufacturers and filling volumes. Single-use bag vendor-agnostic RoSS® shells fosters flexibility and 100% compatibility – no system change required.

RoSS® shells can be stacked one over another leading to huge savings in cold storage rooms and shipping costs and is easy to handle. RoSS® maximizes your storage density and minimizes your worries of requiring storage space.

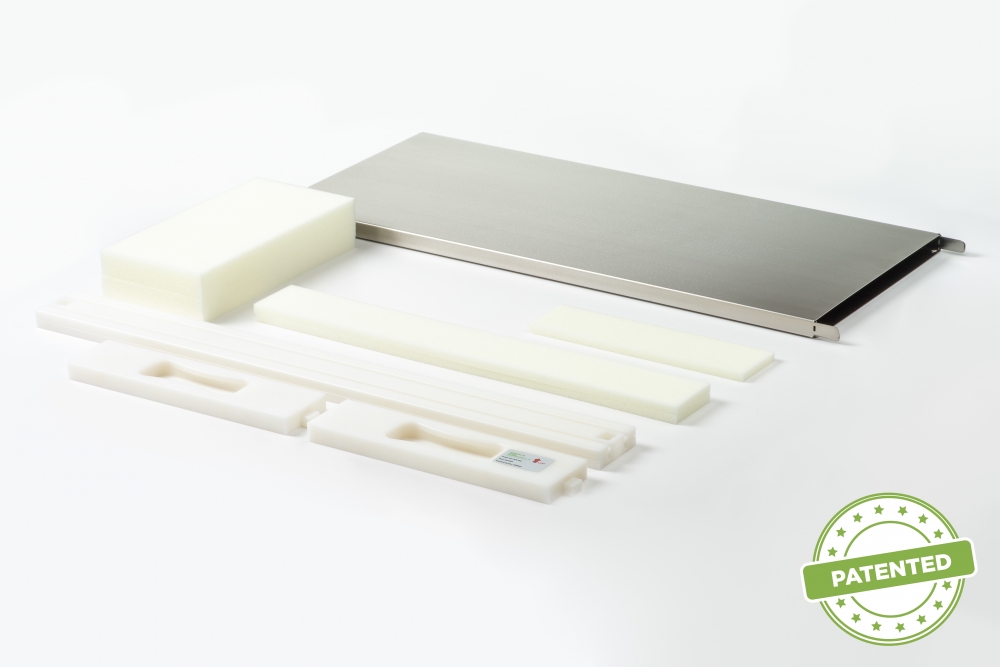

The frames of the RoSS® unit are made of heavy duty plastic that withstands even the lowest temperatures and makes up the static frame of RoSS®. Apart from the guide rails for the stainless steel top and bottom, the frame contains ergonomically shaped grip plates for safe and intuitive handling.

The RoSS® top and bottom are made of high quality stainless steel with the following three advantages:

More details:

What makes RoSS so special? How is the protection and immobilization of the bag secured? See some of many advantages of the protective shell, explained by Johannes Kirchmair, co-innovator of the RoSS shell system.

Liquid bulk drug substance is of utmost value after manufacturing from Biopharma industries. The single-use bag independent platform RoSS helps to avoid product loss through breakages through robust composition and makes it possible to introduce your flexible end-to-end solution in drug substance logistics. Bag independent. Robust. Scalable. Immobilized Bag.

Do you already have the RoSS shell and unsure how to insert your Sartorius 12L Celsius single-use bioprocess container into its dedicated protective container? Check out our instruction for use videos per bag manufacturer here.

Do you already have the RoSS shell and unsure how to insert your Merck/Millipore 20L Mobius single use bag into its dedicated protective container? Check out our instruction for use videos per bag manufacturer here.

Click here to download technical product data sheets, design videos, as well as a case studies and more.

Click here to download technical product data sheets, design videos, as well as a case studies and more.

Datasheet RoSS Shell

Filesize: 0.6 MB – Mime-Type: application/pdf

Whitepaper: Robust Storage & Shipping - The secondary packaging for every single-use bag

Filesize: 1.18 MB – Mime-Type: application/pdf

Case Study - RoSS Shell Storage Density

Filesize: 0.39 MB – Mime-Type: application/pdf

Instruction for Use - RoSS® Shell

Filesize: 1.25 MB – Mime-Type: application/pdf

Sustainability Overview - RoSS Shells

Filesize: 1.15 MB – Mime-Type: application/pdf

Study: Resistance of RoSS Shells against vaporized hydrogen peroxide (H2O2)

Filesize: 0.11 MB – Mime-Type: application/pdf

Datasheet RoSS Shell Accessories

Filesize: 1.92 MB – Mime-Type: application/pdf

Case Study - Bioburden Testing of RoSS Shells

Filesize: 0.28 MB – Mime-Type: application/pdf

Yes, sample bags for various sizes, from small to several 100 ml, can easily be placed in RoSS®. This provides tamper-evident protection for the sample bag (or ID).

Upon request, RoSS® Systems are available for sample bags exclusively.

Yes, any partial filling volume is possible with the patented RoSS® technology. The most recent data sheet with all RoSS® versions and details regarding partial filling is available in the download area or via our contact form.

RoSS® is basically compatible with all standard freezing technologies, from static (lab) freezers to blast freezers and plate-based freeze-thaw units. For a scalable process and maximum product quality, we recommend the latter. Read more about Freeze-Thaw.

In any. In case of uncertainties, please contact Single Use Support GmbH.

There is a variety of options to seal RoSS® tamper-evidently (labels, cable ties, …) in order to make any unwanted opening of RoSS® evident.

Generally, RoSS® is very robust and thus reusable – however, in order to guarantee the highest possible protection, we advise against it.

Yes. You can put a single-use bioprocess container with long tubing and sterile connectors into our RoSS® shells. In this video we will explain how easy this works.

Yes, RoSS® is suitable for temperatures up to -200°C (-328°F).

We developed a system called Cryo Control Unit (CCU) which is an insolation material styro foam piece that covers the shoulders of the single-use bioprocess container and the shell. CCU is meant for enabling the use of RoSS® shells in standard lab freezers or in blast freezers.

Yes, both options are possible. Either fill the bag and place it in the RoSS® System or place the empty bag in the system and fill it with a fully automated filling system, compact and with little air. Learn more about RoSS.FILL.