ADC manufacturing: Process, Challenges & Solutions

Table of contents

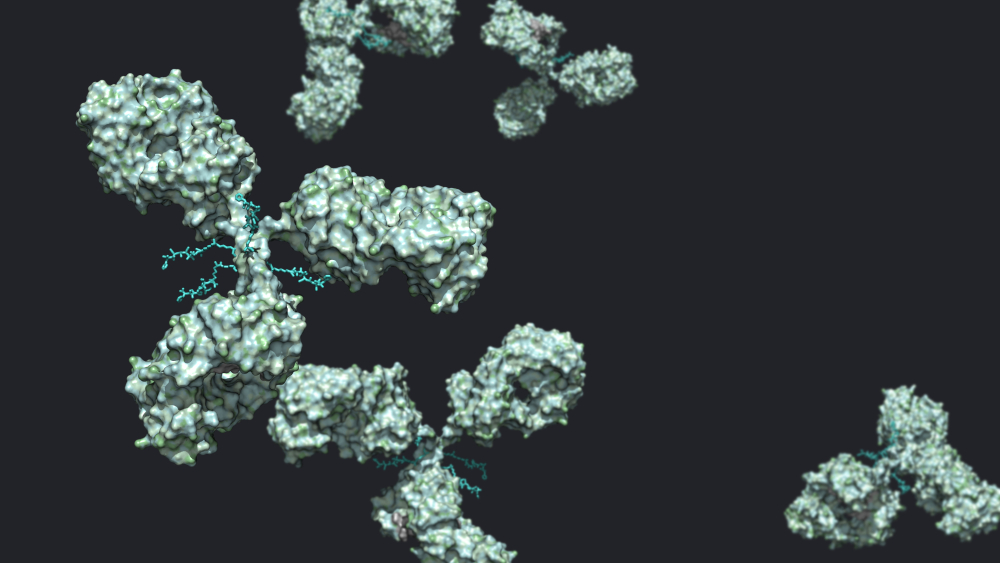

ShowAntibody drug conjugates (ADCs) are a promising alternative for cancer therapy. Due to the targeting quality of the monoclonal antibody (mAb) in combination with a highly toxic payload drug, it becomes easier to target cancer cells without potential harm to healthy cells which is a big advantage to common chemotherapeutic methods. Because of the potential of this formulation, process development has become a growing field of interest for the pharma industry.

However, the high toxicity of the product also bears a lot of challenges which need to be overcome. Scale-up and industrial production of ADCs face complications due to the high safety measures which need to be taken to guarantee product efficacy and a protected working environment for staff and manufacturers.

In this article we seek out to give you an overview of the ADC production process and the different challenges during manufacturing while also introducing solutions which help to ensure aseptic production methods through single-use-technologies and end-to-end systems.

ADC manufacturing process

Antibody drug conjugate manufacture involves the aggregation of three key compounds through bioconjugation techniques:

- a monoclonal antibody

- a payload, typically a cytotoxic drug or small molecule, and

- a stable linker.

Through the combination of the tumor targeting quality of the monoclonal antibody and the drug, it becomes possible to deliver effective cytotoxins directly to cancer cells without the risk of damaging healthy ones.

The steps to manufacture ADCs each bear their own challenges.

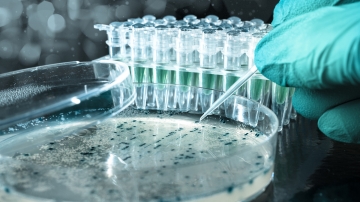

MAb production and characterization is an important step in the successful outcome of ADC production. The antibody needs to have specific binding qualities to recognize the cancerous cells and deliver the drug to its target. mAbs are sensitive protein structures which are prone to contamination and product loss during production. Producing them on a large scale requires the right equipment and expertise, often involving the use of a cell line optimized for the production of the monoclonal antibody.

The purification process is a critical part of ADC manufacturing, with tangential flow filtration (TFF), a form of ultrafiltration, playing a key role in separating and purifying the desired substances from impurities. This ensures high-quality mAbs and other ADC components are used in the production process.

Managing drug development and bioconjugation through a drug-linker presents similar challenges. The combination of the drug and linker creates intermediates that must be carefully managed to ensure the stability and efficacy of the final ADC product. There are many details which have to be considered before an ADC enters the market.

ADCs are a novel solution for cancer or autoimmune diseases and its market is growing. Many ADCs are currently in preclinical development or in ADC clinical trials waiting for their FDA approval, as well as many assays in validation.

In most cases different parties and departments are involved in the production and these steps are carried out by different biopharmaceutical manufacturing services as they require specific equipment, manufacturing environments and in-depth knowledge. Due to this instance, it is often necessary to transport ADC bulks from one manufacturing facility to another.

To provide safe handling of ADCs it is important to decrease risk of product loss through breakage, of temperature deviations at ultra-low temperatures and of disruptions of the supply chain. To make this possible, they have to be kept at -80 degrees.

ADC manufacturing challenges

There are a lot of challenges associated with ADC production. The main goal is to create an efficacious and safe-to-use product.

The biggest challenges in ADC manufacturing are as follows:

- manufacture of an efficacious & safe-to-use product

- diminish exposure of toxicity (closed systems without manual handling are necessary)

- scalability (modular systems help to scale, transferable processes from lab to commercialization)

- product loss (will be minimized by single-use technology)

- contamination and impurities (worst-case scenario that must not occur)

Following current good manufacturing practices (GMPs or cGMPs) is advised to achieve standardized manufacturing processes.

cGMP compliant ADC production

Since ADCs are highly hazardous substances, GMPs help protect employees and the environment from coming into contact with it. Therefore, quality control has to start right from modifying and purifying mAbs to combination with an effective cytotoxin through a stable linker, while maintaining the right drug-antibody-ratio (DAR).

Aseptic manufacturing plays an important part in the quality control of ADCs and helps to ensure that the biotherapeutic is not contaminated.

To make sure that no alterations occur during the manufacturing chain, controlled freezing and thawing of ADCs is important for an efficient and successful production without product loss.

These special conditions make ADC manufacturing a time consuming, cost intensive and laborious process. However, new technologies and developments in the production process help for optimization, streamline each step and reduce the risk of product loss.

As an example, fully automated and closed end-to-end processes based on single-use solutions fulfill cGMP requirements and make flexible, scalable, efficient manufacturing possible.

Ensuring high quality of all components

As mentioned before, quality control is one of the most important components of the manufacturing process as ADCs can be prone to contamination and product alterations are a high potential health risk for cancer patients. Therefore, every part of the production process from mAb production to drug substance manufacturing and conjugation has to be monitored at all times before the ADC enters a chromatography system and has to go through purification filtration.

Safe & efficient freeze & thaw solutions

The importance of controlled freezing in the production of ADCs has already been stated above. To answer the question what exactly is meant by controlled freezing, it is necessary to dive a bit deeper in the technique behind it.

In contrast to commonly used freezing mechanisms, controlled freezing becomes possible through plate-freezing technology. Two plates distribute temperature evenly on both sides of a container which reduces the risk of drug denaturation, cryoconcentration and vacuums within the soluble which can alter the ADCs efficacy. This method minimizes the risk of drug denaturation, cryoconcentration, and vacuums within the solvent, which can impact the efficacy of ADCs.

Through using single-use containers it not only becomes easier to safely freeze substances, but they also allow for controlled thawing at the optimal rate for each product. Further, storage is made easier, more efficient, and at higher storage density.

Safe & efficient aseptic filling solutions

Due to the sensitivity of protein structures and the high toxicity of the drug molecule, ADC manufacturing is a risk prone process. Aseptic filling is a necessary process step to aliquot bioconjugates into bioprocess containers for safe storage and shipment. Automated end-to-end processes and closed systems with single-use equipment are the solution to the problem of contamination risks during filling. They reduce product loss through residual volume and the risk for human errors, keeping the soluble contamination-free and manufacturers safe.

Costs as a Challenge

In addition to health and safety concerns and quality controls, of course costs are an issue to consider. The field of ADC manufacturing is constantly growing due to its benefits compared to common chemotherapies.

However, cost, time and labor-intensive processes are obstacles in ADC manufacturing. Nevertheless, single-use technologies are about to change these conditions. They are a way to combine all of the aforementioned regards by streamlining the process through fully automated aseptic filling, controlled freezing and thawing methods and closed systems to ensure the required purity of the drug.

For this reason most of the contract manufacturing organizations (CMOs) and contract development and manufacturing organization (CDMOs) operating in different aspects of ADC development or ADC processing like antibody manufacturing or synthesis of biologics rely on single-use technologies because they are the most cost and time efficient way to ensure the safe use of the product.

Single-use solutions for ADC manufacturing

Single-use technology and equipment was designed to make every step of ADC manufacturing and the management of hazardous fluids more efficient. End-to-end systems support CMOs and developers in their mission to a successful production of a safe-to-use product.

Single Use Support supports manufacturers and contract manufacturers in ADC production with its automated end-to-end solutions based on single-use technology to overcome the manufacturing challenges.

Through single-use technology it is possible to cover the different steps from primary packaging in a protected single-use container to scalable filling without product loss or contamination and controlled freezing. Storage and transport while maintaining the right temperature levels in closed systems guarantees product quality to ensure the safe use of the product after thawing it at a controlled rate. As all of these steps are performed in a closed system, pollution risks are minimized.

FAQs about ADC manufacturing

What is the process of ADC production?

ADC production involves mAb production, drug-linker synthesis, conjugation, purification, and quality control, following cGMP standards to ensure safety and efficacy.

How many approved ADCs are there worldwide and in the USA?

As of recent data, there are around 20 ADCs approved worldwide, with around half approved in the USA. Read more: FDA approved ADCs.

What are the benefits of ADCs?

ADCs target cancer cells specifically, minimizing damage to healthy cells and enhancing the therapeutic index of cytotoxic drugs.

What are the challenges in ADC manufacturing?

Challenges include controlling impurities, toxicity, contamination, product loss, scalability, and maintaining regulatory compliance throughout the manufacturing process.

What are future solutions in ADC manufacturing?

Future solutions involve optimizing cell lines, improving linker technologies, enhancing conjugation methods, and advancing single-use systems to increase efficiency and safety.