Storage Density in Biopharma Manufacturing Facilities

Table of contents

ShowEspecially manufacturing plants with high commercial production of biopharmaceuticals face limitations in storage space.

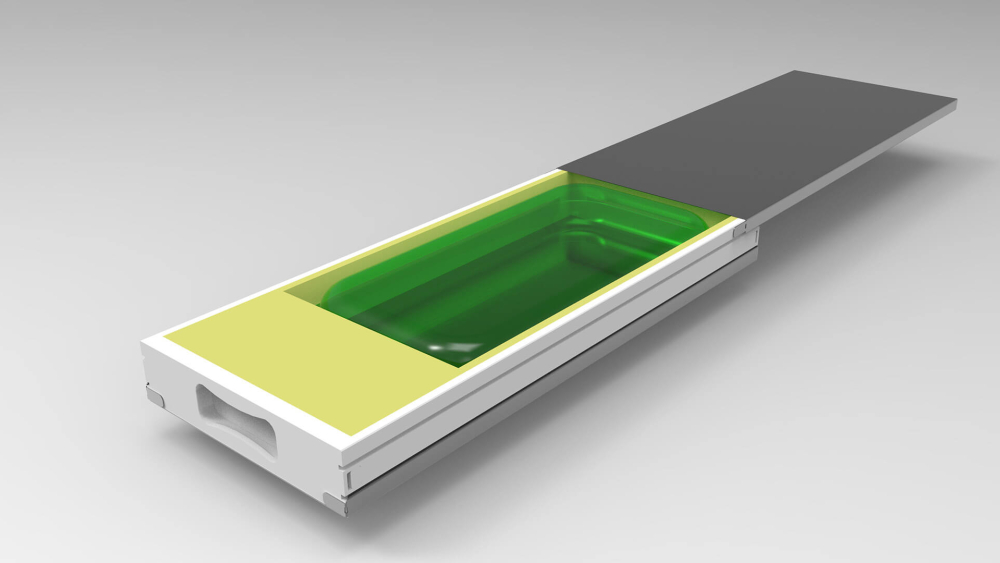

Single-use bags with its flat shape is predestined for stacking and offer great solutions to increase storage density on-site but also for shipment.

The combination of both, single use bag and RoSS® shells (Robust Storage and Shipping) makes them a cost-effective solution, as they require little storage space. RoSS® shells are available for all sizes and suppliers of single-use bags.

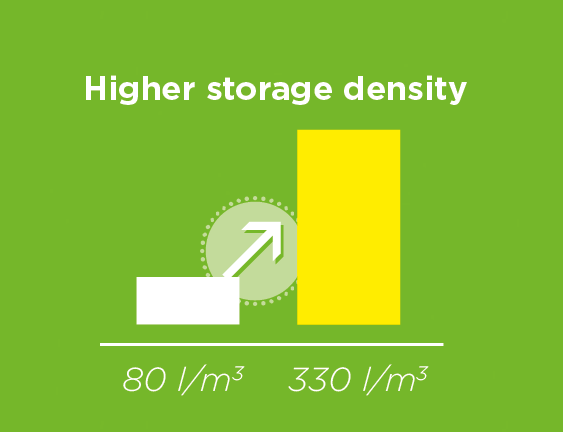

Comparing single use bags to PE bottles, the cold room storage density with single-use bags is almost 4 times higher.

For example, 5L bottles can be stored at a density of about 80L/m3 whereas single-use bags offer a density of approx. 330L/m3, which leads to significant cost savings and future growth without having to invest heavily in cold room storage capacities.

The rectangular design of RoSS® enables huge optimization for Biopharma companies in terms of storage density, irrespective of what single use bag is inside.

Thomas Wurm, CEOLong term ultra-cold storage

The dependence on blast & static freezers for storage and cooled storage rooms and the subsequent limitations due to incompatibility to RoSS shell dimensions has proven that there is room for optimization - ultra cold fridge for lab.

RoSS.ULTF, the cold storage end-to-end platform, helps to maximize the storage density of RoSS® shells as it is compatible to all RoSS® shells and sizes on the market.

RoSS.ULTF offers not only a great relief for storage capacities due to its high storage density and stackability of RoSS® shells, but is also another way out from incompatibilities of technologies due to its tailored design. It enables a seamless transition between deep-freezing (RoSS.pFTU) and shipping (RoSS.SHIP) or thawing in an end-to-end process with a high degree of flexibility in-plant due to its portable use.

Shipping

The advantages in storage space when using RoSS® also facilitate shipping. As frozen single-use bags could not be safely stacked without a robust secondary packaging without risking breakages and severe product losses, RoSS® offers better solutions for in-plant storage, in-plant transportation, and international shipping.

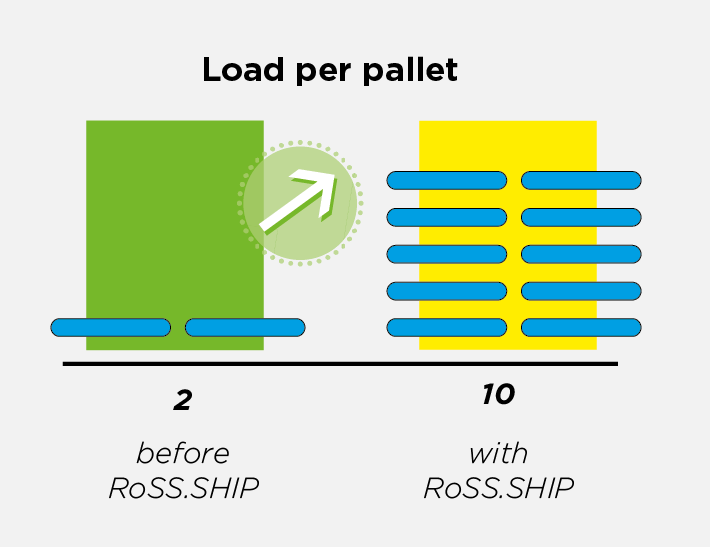

Previously, it took one pallet to transport 2 bags. After the introduction of RoSS.SHIP, 10 bags – 120 liters of BDS (bulk drug substance) – could be filled into one pallet. This is a reduction of storage space during transportation by 80%. Consequently, the increased storage density not only had an impact on the storage space, but also on the volume of freight in trucks and airplanes and less labor hours through more efficient handling of the deliverable.