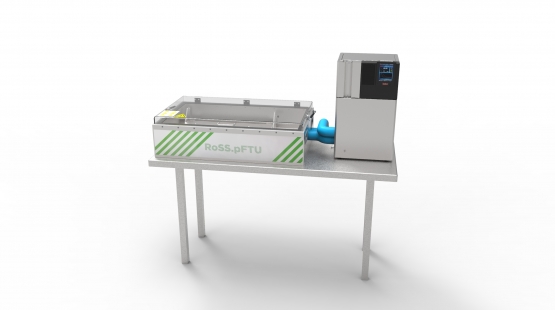

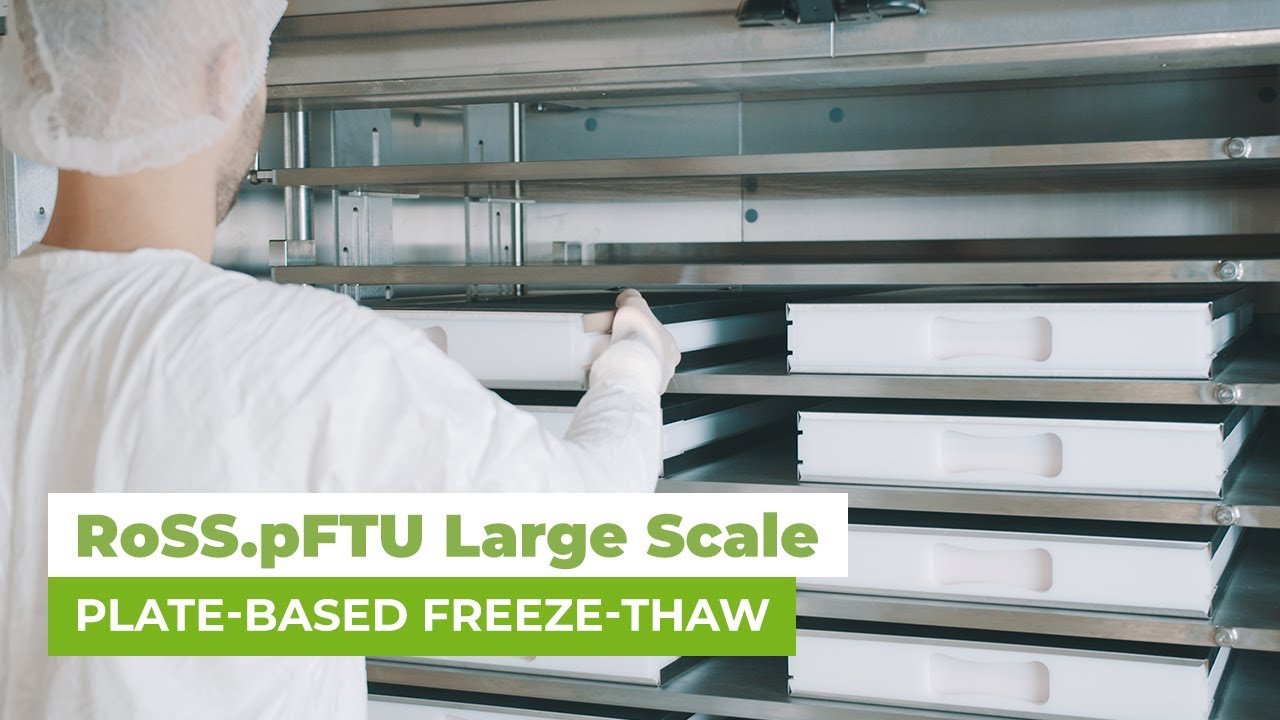

The Single Use Support freeze-thaw platforms provide reliable end-to-end solutions, such as plate freezers for the controlled freeze/thaw processes of any drug substance - either for clinical phases or commercialized bulk production.

Our new freeze-thaw units are fully scalable and compatible with all batch sizes and bags from all established manufacturers – you will only require one single system from the lab to blockbuster production.