Shipping pharmaceutical liquids and its challenges

Table of contents

ShowThe global distribution of pharmaceuticals is complex and demanding, requiring precise handling and storage of sensitive products. With the rise of personalized medicine and the increasing globalization of the industry, the need for safe and efficient shipping and supply chain has never been more important.

In this article, we will discuss the specific challenges of shipping pharmaceutical liquids, including the importance of maintaining the cold chain, the associated risks and the regulations that must be followed. We will also explore the innovative solutions that single-use technology offers to address these challenges, and how they provide efficient and scalable options for safe shipping in the biopharmaceutical processing industry.

Pharmaceutical shipping: an introduction

The shipping of drug products is a crucial aspect of the pharmaceutical supply, especially when it comes to the transportation of liquids, which require special handling and storage conditions to maintain their potency and effectiveness. With the globalization of the pharmaceutical industry and the production of bulk drug substances taking place in multiple countries, shipping is a major challenge for pharmaceutical companies.

The importance of safe and efficient shipping processes cannot be overstated, as the timely and safe delivery of life-saving drugs and vaccines, directly impacts patient outcomes.

To meet this challenge, it is important to have clear and effective processes in place, along with the right tools and technologies to support them. This applies to everything from packaging and labeling to documentation and controlling the temperature range of temperature-sensitive prescription drugs.

Challenges in pharmaceutical shipping of liquids

Shipment of liquid pharmaceuticals presents a number of challenges, including maintaining the cold chain and managing risks, such as product loss, contamination, and cargo theft.

Cold chain in shipping

Cold chain logistics is an important part of pharma logistics, as approximately 70% of drug products require proper temperature control. Maintaining the correct temperature during storage and transportation is crucial to preserve the quality and effectiveness of these products. Even small temperature fluctuations of two degrees (2 Kelvin) can render a pharmaceutical product useless, making the maintenance of the cold chain a top priority in pharmaceutical shipments.

Proper management of the cold chain in pharmaceutical logistics involves the use of refrigerated warehouses, specialized biopharma packaging, and sometimes climate-controlled trucks. Equally necessary are regular vehicle inspections to protect the products from external elements and maintain their proper temperature until its final destination. This is particularly important for liquids, such as mRNA or monoclonal antibodies, which must be stored and transported at -80 degrees, and gene-modified cell therapies, which require cold storage and transportation at -150 degrees.

Specialized packaging enables conventional transportation. RoSS.Ship from Single Use Support for example keeps the required temperature up to six days. 1

Risks in pharmaceutical shipping

The transport of pharmaceutical liquids presents various risks that must be considered. Besides the previously mentioned risks of product degradation due to temperature control issues, there is also the risk of contamination or theft.

If the protection is inadequate, breakages will occur, leading to contamination and loss of the entire product. High costs for the loss of the valuable substances are the consequence.

Furthermore, high-value prescribed drugs, such as opioids, are particularly susceptible to theft during transit, which can have significant consequences for the pharmaceutical companies, pharmacies, and patients.

Shipping personalized medicine, with its low-volume but high value, presents additional challenges as it requires specialized temperatures and handling. To address these risks, it is critical to choose a reliable carrier and (drug substance) logistics partner to plan ahead shipping specifications, including the proper temperature control requirements and handling instructions.

Single Use Support has come up with a solution to this challenge by developing small single-use bags and a shell that is specifically designed for this purpose. These innovative products ensure the safety and effectiveness of personalized therapies, even when shipped in small volumes.

2

Obstacles of shipping personalized medicine

One of the major challenges, shipping personalized medicine is the issue of cost and efficiency, especially when shipping small volumes. This is particularly the case for personalized therapies such as CAR-T cell therapy, which involves transporting of small blood bags containing genetically modified cells at extremely low temperatures of -150 degrees Celsius. To maintain the safety and efficacy of such therapies, it is necessary to use specialized packaging, warehousing and handling methods.

Regulations in pharmaceutical shipping

Shipping pharmaceuticals is a complex process that requires strict compliance to ensure that the final drug product meets quality standards. Regulatory agencies such as the Food and Drug Administration (FDA) and the European Medicines Agency (EMA) have established clear guidelines for the shipping industry to follow when transporting liquids through single-use systems. According to PDA’s TR66 technical report, transportation systems must be properly designed and tested in consultation with a packaging engineer to be considered qualified.

To comply with these regulations, companies must conduct a risk assessment of potential impacts on the product during shipment, such as vibration, handling, delays, and seasonal variation. This requires conducting tests based on international standards like ASTM D4169 or ISTA 3 series.

These standards provide standardized validation methods that simulate shipping hazards and evaluate the effectiveness of protective packaging and the product's ability to withstand these hazards. It is important to consider solutions that comply with these regulations.3

Safe shipping of pharmaceutical liquids with single-use systems

Single-use systems offer safe and efficient solutions for the shipping of frozen pharmaceutical liquids. The solutions include fully automated filling of drug substance into single-use bags, protected by shells from any shock during transport, automated freezing to the desired temperature on a freeze-thaw platform and efficient, space-saving storage in a shipper that maintains the desired temperature for six days. Single-use systems can provide scalable solutions, from a few mL for cell therapies to several 1000L using multiple large 50L single-use bags, and comply with ISTA and ASTM regulations.

The use of single-use systems for storing, refrigeration and shipping frozen biopharmaceuticals offers advantages such as universal application, process flexibility and efficiency, reduced capital and labor costs, and no need for cleaning and sterilization. Storing and shipping biopharmaceuticals at frozen state ensures the biological integrity of the drugs and simplifies compliance with temperature check requirements.

Advantages of single-use systems for shipping:

- Scalability

- High flexibility

- Safe (<0.001% product loss)

- Space-saving

- Sustainable

- Reduced operating costs

- ASTM & ISTA compliant

Conclusion: Shipping of pharmaceutical fluids

Shipping pharmaceutical liquids is a complex process with numerous challenges and risks, including the potential for high losses due to the expensive nature of biologics. It is not enough to blindly trust a logistics company and a third-party provider. End-users must take responsibility to mutually plan with providers to ensure the proper handling of their shipments.

Solutions are available to help end-users navigate the complexities of shipping pharmaceutical drug substances. Single Use Support provides personalized support to help customers find the right solution for their specific needs. They understand that each shipment of liquids has its own unique requirements and offer customized solutions to ensure safe and efficient pharmaceutical transport.

FAQs about shipping of pharmaceuticals

How do you ship pharmaceuticals?

Pharmaceuticals must be securely packaged to withstand shock and vibration and maintain the correct temperature. Single-use systems offer excellent solutions for shipping pharmaceuticals.

What is pharmaceutical temperature controlled transport?

Temperature-controlled transport of pharmaceuticals refers to the temperature management of pharmaceutical products during transport to ensure their quality and effectiveness. Solutions like RoSS.SHIP from Single Use Support are designed to provide temperature-controlled transport.

What is primary and secondary packaging in biopharma?

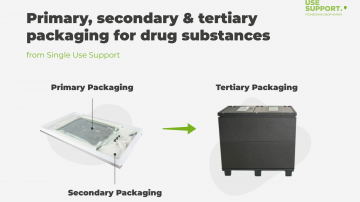

Primary packaging refers to the direct contact packaging of a pharma product, such as a vial, syringe or a single-use bag. Secondary packaging refers to the outer packaging, that provides additional protection to the primary packaging during transport and storage. For example, protection of brittle single-use bags during cold chain with a safe shell like the RoSS® Shell from Single Use Support. Tertiary packaging refers to the outer packaging such as a box or shipping container which contains the shell with the protected single-use bag inside. Read more: Primary and secondary packaging for drug substances

- How to overcome the challenges facing the pharmaceutical cold chain industry?, https://geodis.com/de-en/blog/vertical-logistics-expertise-and-special-events/how-overcome-challenges-facing-pharmaceutical, Published 28.02.2023

- RISK ASSESSMENTTRANSPORTATION OF MEDICINAL PRODUCTS, https://helda.helsinki.fi/bitstream/handle/10138/304382/Viitanen%20Elina%20Risk%20assessment-%20transportation%20of%20medicinal%20products.pdf?sequence=1&isAllowed=y, Published 28.02.2023

- An Integrated Approach to Shipping Liquid in Single-Use Systems, https://www.pharmtech.com/view/integrated-approach-shipping-liquid-single-use-systems, Published 28.02.2023