Single-use bag manufacturers: the major players

Table of contents

ShowThe demand for disposable bags is influenced by key industry players who acknowledge the market's requirement for dependable safeguarding of crucial and high-value goods within the biopharmaceutical sector. This includes intermediates as well as final drug products like gene therapies.

This article provides an overview of various manufacturers producing single-use bioprocess containers. In April 2022, Single Use Support joined the market, introducing the IRIS single-use bag as its solution.

History of single-use bags

The inception of single-use technology in the biopharmaceutical industry dates back to the late 1970s, primarily in the form of disposable capsules and various filters. Subsequently, the industry embraced plastic film bags and containers initially designed for food storage. The late 1990s and early 2000s witnessed a transformative phase in biopharmaceutical manufacturing with the introduction of large-scale single-use bags (ranging from 50 to 1,600 L), followed by the advent of single-use 2D and 3D bioprocess containers, as well as filter assemblies for mixing and storage systems for intermediates and final products.

In the present day, the term "single-use technology" encompasses a diverse array of disposable, modular, and highly adaptable technologies. These technologies can be scaled not only to different volumes but also to a wide range of applications, spanning upscale bioprocessing, filling, and the entire logistics process. The latest-generation platforms are generally compatible with various bag brands and volumes. A notable example is Single Use Support's RoSS®, which stands out for its bag-agnostic nature and exceptional flexibility due to its modular design.

Single Use Support - single-use solutions

Single Use Support provides products and services around single-use technologies for the Biopharma industry on a global scale. Their solutions increase product safety of liquid pharmaceuticals and drugs during manufacturing processes but also transportation. The company has recently expaned its production facility in Kufstein to a second location in Hall, Tyrol to meet the growing demands and supply chain shortages of the pharma industry.

Their solutions include sterile consumables, platform systems and end-to-end process solutions in order to reduce product loss and optimize cost-effectiveness and various process steps around liquid transfer and manufacturing.

Single-use bag IRIS by Single Use Support

The sterile single-use containers from Single Use Support are the primary packaging to protect liquid substances to ensure 0% product loss during freezing, storage and transportation! Their bioprocess container includes various characteristics:

- Customizable: any size/fill volume, any tubing, any connector, any port fitting

- Highly protective, low permeability, inert PE multilayer film

- Suitable for all freezing technologies

- Gamma irradiated

- Compatible with Single Use Support manifolds for a fully closed sterile ready to use system

- Compatible with the protective RoSS® Shell

The Single-use bioprocess container, made of a combination of EVOH and polythylene, is available from 10mL up to 50L but can be adapted to individual needs in terms of size and tubing connections whilst offering consistent quality.

IRIS Single-Use Assemblies

Whitepaper: Connecting the Dots

Creation of Single-Use Assemblies for Pharmaceutical Fluid Management

Sartorius - single-use solutions

The Sartorius group is a global supplier of pharmaceutical and laboratory equipment, with a focus on bioprocess solutions, laboratory products and services. Established in 1870 by Florenz Sartorius, a German mechanician, the company originated as a fine precision weighing enterprise. Over the years, it diversified its specializations. In the mid-1900s, it emerged as a leading supplier globally for metrological systems tailored for research laboratories and various industries. In the late 1960s, the company was engaged in examining a sample of moon rock brought back by the Apollo 11 mission.

Today, the company has transformed into a key international partner for the biopharmaceutical industry and the research sector, providing solutions for manufacturers and laboratories. Interestingly, Sartorius has come full circle; in 1927, it was among the co-founders of a company manufacturing membrane filters. These filters, which became integral to today's bioprocess business with the rise of biotechnology in the late 20th century, showcase the company's enduring commitment to innovation and evolution.

Sartorius Flexsafe® single-use bag

Leveraging over two decades of expertise in crafting single-use fluid management solutions, Sartorius has introduced the Flexsafe® single-use bag, a proven Pre-Designed Solution (PDS) tailored for various processes, such as harvesting, filtration, feeding, storage, and shipping of media, buffer, downstream intermediates, drug substances, and drug products. The Flexsafe® line includes both 2D and 3D single-use bags and containers, spanning from 20 ml to 3,000 L. This comprehensive range ensures consistency and control across every step of the bioproduction process.

Sartorius Flexboy® single-use bag - 2D bag

The Sartorius Flexboy® single-use bag represents a 2D bag variant, obtainable in bag chamber volumes ranging from 5 ml to 50 L. This adaptable series of Flexboy® Pre-Designed Solutions (PDS) facilitates the handling of any biopharmaceutical fluid, including sterile filtration, transfer, and storage. The diverse configurations offered are designed for seamless integration into various process steps.

Entegris - single-use bag assemblies

Entegris, Inc. serves as a supplier of products and systems crucial for purifying, safeguarding, and transporting critical materials. Renowned globally in advanced materials science, the company collaborates closely with leading manufacturers to drive continuous technological progress. Established in 1966 and headquartered in Massachusetts, Entegris operates worldwide, aiming to assist manufacturers in optimizing yields through enhanced contamination control in vital processes, such as bulk substance processing.

Their extensive range of offerings encompasses filtration products for purifying gases, fluids, and laboratory environments, as well as liquid systems and components designed for dispensing, controlling, analyzing, or transporting process fluids.

Aramus™ 2D single-use bags

The Aramus™ 2D single-use bags are crafted from fluoropolymer film that is gamma-stable, ensuring exceptional purity and reliability. These bags can endure a broad range of operating temperature, including cryogenic temperatures, without degradation. The range includes both 2D barrier bag systems and 3D multilayer assembly bags, meeting all necessary criteria for safety, storage, and transportation of sterile liquids.

Merck Millipore - Mobius® single-use manufacturing

Merck Millipore is a prominent supplier to the life science industry, tracing its roots back to a family-operated pharmacy established in Darmstadt, Germany, as early as 1668. Over the centuries, it has evolved into a globally operating pharmaceutical and chemical company with a multibillion-dollar footprint. A significant milestone in Merck's journey occurred in 1827 when Emanuel Merck isolated and characterized alkaloids, laying the foundation for its transition into a research-driven industrial entity.

As Merck continued to expand, it introduced new ultrapure products and pioneered the first biotechnology production processes. In 1954, the Millipore Corporation was founded, known under the name MilliporeSigma in the United States and Canada. The origins of the "Millipore" name stem from the Lovell Corporation's contract with the U.S. Army Chemical Engineers in the early 1950s, aiming for the development and production of membrane filtering devices for the separation of molecular components within fluids. This part of the company's name originates from the multitude of minute openings that charachterized their microporous membrane product.

Merck Millipore Mobius® single-use bags

The Mobius® 2D pillow-style assemblies, featuring Merck's NovaSeal™ sealing technology, come pre-sterilized and ready for use in a diverse range of biopharmaceutical applications, including formulation and storage of sterile solutions. These assemblies are offered in volumes ranging from 50 mL to 50 L.

For larger applications, Mobius® 3D drum assemblies are available in volumes between 50L and 200L, suitable for tasks such as sterile fluid or buffer storage. Additionally, Mobius® 3D collapsible bins are designed to handle containers with volumes ranging from 250L to 1000L, providing versatility across various production steps.

Thermo Fisher single-use bags

Thermo Fisher Scientific specializes in manufacturing scientific instrumentation, reagents, consumables, software, and services. They supply these products to healthcare providers, life science entities, and similar industries. The company was formed in 2006 through the merger of Thermo Electron, a provider of analytical instruments, and Fisher Scientific, a company focused on lab supplies and biotechnology.

Thermo Fisher Scientific offers a range of products, including containers for the biopharmaceutical industry. These containers serve to eliminate the need for post-use cleaning steps associated with reusable containers and help in reducing the risks of cross-contamination.

Labtainer® single-use bags - BioProcess Container Systems

Labtainer® single-use bags cater to small-volume liquid handling requirements. These bags are adaptable in size and present a range of standard configurations to accommodate various application needs. Constructed from CX5-14 film, these bags are not only space-saving but also ergonomic. Their applications span diverse fields, including:

- Harvesting, feeding, and collecting samples from bioreactors and fermenters.

- Preparation and storage of buffer, culture media, and process liquids.

- Chromatography feeding and collection of fractions.

Cytiva single-use 3D bag assemblies

Cytiva, formerly known as the GE Healthcare Life Sciences biopharma business, underwent a name change following its acquisition by Danaher Corporation in 2020. As a global entity, Cytiva offers technologies and services aimed at advancing and expediting the development and manufacturing of therapeutics. Headquartered in Massachusetts, with operations worldwide, Cytiva provides tools and services to companies and scientists engaged in biological research. Their offerings span a wide spectrum, encompassing bioprocessing, genomics, and cell and gene processing. In addition to general laboratory supplies, they also supply filters and other crucial single-use components to the industry.

Fortem® single-use film

The increasing popularity of single-use bags throughout the biopharmaceutical development and production process has spurred a demand for reliable materials capable of withstanding rigorous tests for flexural fatigue, weldability, and abrasion resistance. Extensive analyses are carried out on the Fortem film to find and manage degenerative products.

Developed in compliance with the latest industry guidance and testing protocols, Fortem is tailored to ensure pH stability during liquid storage and transport. Additionally, it creates a protected environment suitable for cell culture applications. Known for its flexibility and versatility, Fortem offers bags in diverse shapes and sizes to accommodate various volumes and address the needs of both laboratory and manufacturing environments.

Allegro® 3D single-use bag biocontainers

The Allegro® 2D biocontainer systems are packaging solutions with extremely low amounts of extractables and leachables, and come with a high degree of chemical compatibility.

Formerly sold by PALL until the integration of the company’s life sciences business into Cytiva in 2023, these single-use systems are available in various sizes. This facilitates scale-up and increases flexibility.1

Avantor single-use bag solutions

Headquartered in Pennsylvania, Avantor stands as a leading global provider of mission-critical products and services, catering to industries such as biopharma and healthcare. Established in 1904 with the aim of producing chemicals of the "highest degree of purity commercially available," as articulated by founder J.T. Baker, the company has experienced remarkable growth. Starting with just 20 employees, Avantor now boasts over 12,000 associates and operations spanning more than 30 countries.

Alongside its considerable size and manufacturing and distribution capabilities, Avantor's product portfolio has expanded significantly. Among its diverse range of services and products, Avantor offers open-architecture, single-use solutions compatible with various platforms and technologies. Specifically, their single-use bioprocessing bags are designed for transferring and storing products throughout the drug-manufacturing process. Available in various sizes, these single-use bags cater to a multitude of applications in bioprocessing.

Saint-Gobain single-use bioprocess bags

Saint-Gobain, a French multinational corporation established in Paris in 1665, initially began as a mirror manufacturer. Over time, it has diversified its production to include various construction, high-performance, and other materials, serving industries such as pharmaceuticals and medical. In the medical sector, Saint-Gobain's branch is dedicated to designing, manufacturing, and distributing medical components for processing or use in the manufacture or assembly of medical devices, including finished devices made on behalf of medical device manufacturers.

Among Saint-Gobain's array of components, single-use bioprocess bags are featured. These bags, spanning from 50 mL to 3,000 L, are produced with a multilayer film optimized for bioprocessing. The film materials used are both bio- and chemically compatible.

Gore single-use solutions

Founded over 60 years ago in Delaware by a husband-and-wife team to cater to the electronic products market, Gore has a notable history. In 1969, the son of the founding couple, Bob Gore, made a groundbreaking discovery - a remarkably versatile new polymer known as polytetrafluoroethylene (PTFE). This discovery propelled the company into diverse applications across various industries, including medical, pharmaceutical, biotechnology, oil and gas, and even aerospace.

Today, Gore's portfolio encompasses a broad spectrum of products and solutions, extending to single-use bags designed for use in the biopharmaceutical industry.

GORE® STA-PURE™ single-use bags - Flexible Freeze Containers

Gore's single-use bag containers are specifically crafted for the storage and transport of frozen drug substances. These bags are made from exceptionally robust and durable materials, ensuring they can withstand extreme temperatures and mitigate the risk of becoming fragile and brittle in low-temperature environments.

The use of a high-purity, biocompatible fluoropolymer film with low extractables makes these bags well-suited for bioprocess applications. Available in sizes ranging from 50 ml to 12 L, these bags are compatible with various single-use platforms, providing flexibility and adaptability across different applications in the biopharmaceutical industry.

Single-use shell systems available on the market

In the previous chapters, we have discussed some of the most important manufacturers of single-use bags. But the rise and common acceptance of single-use bags as containers for high-quality drug substances in the biopharmaceutical industry has also brought with it the need for protective shells to keep the bags and their content safe and protected during storage and on their way to their final destination.

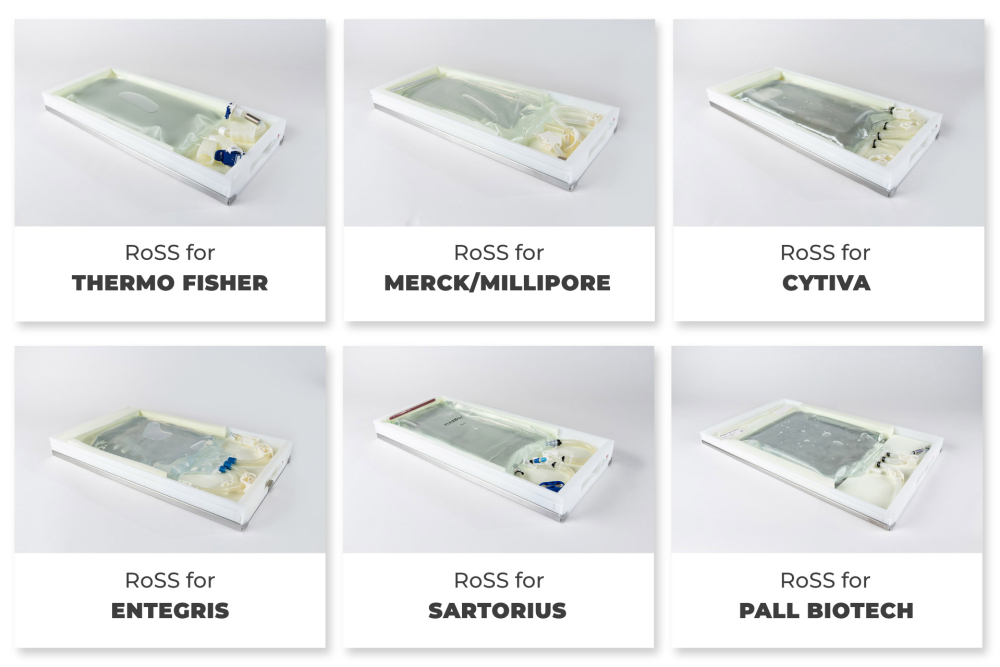

Accordingly, there are several providers of protective packagings; however, Single Use Support is the only supplier of solutions that can protect all the aforementioned bags, increasing flexibility and scalability of biopharma processes.

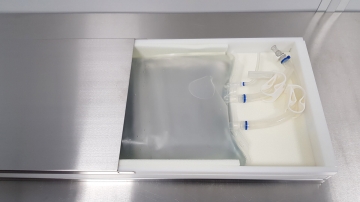

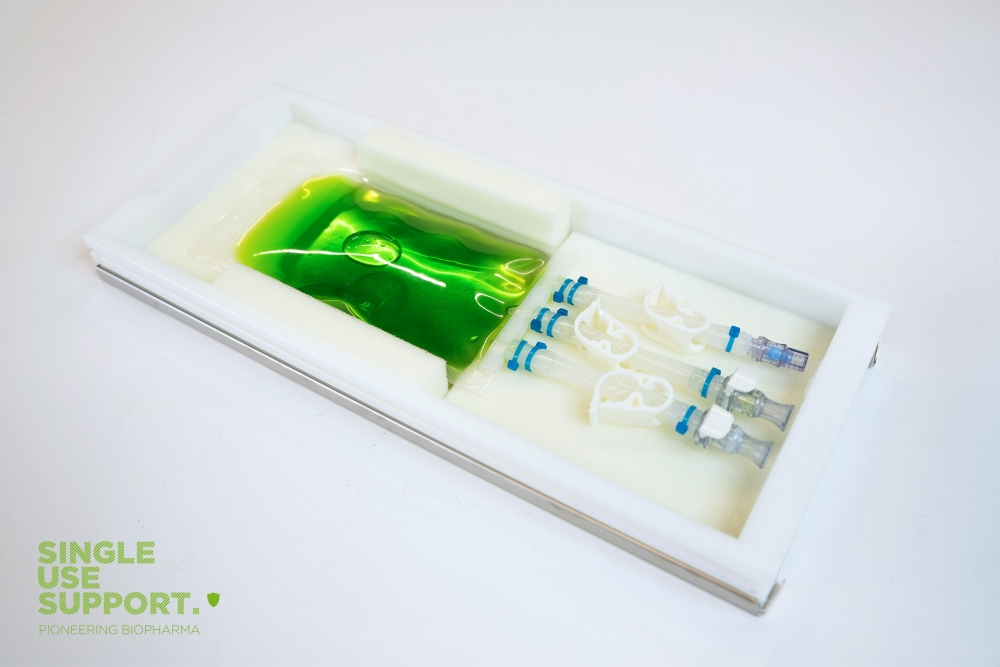

Single Use Support RoSS® storage and shipping system

The RoSS® shell developed by Single Use Support is made of stainless steel, thus allowing for a faster transfer of temperature, which in turn leads to more consistent freezing results. On the inside, those stainless-steel shells are equipped with 3D foam to add further protection against external shocks. RoSS® shells are tamper-proof and can be monitored throughout the journey. They are bag agnostic and adjustable, meaning they are compatible with single use bags of any established brand.

RoSS® shells form part of the flexible and scalable RoSS system, which can be adjusted to a range of volumes as well as different requirements. Thanks to its modular design it allows for the addition of filters, connectors and other add-ons as needed. Push your production and logistics processes to the next level and find out more about RoSS® and its compatibility with brands such as Sartorius, Entegris, MerckMillipore and many more by following this link.

- Cytiva and Pall Life Sciences complete integration to create a global innovation and solutions leader in biotechnology , https://www.prnewswire.com/news-releases/cytiva-and-pall-life-sciences-complete-integration-to-create-a-global-innovation-and-solutions-leader-in-biotechnology-301812144.html, Published 5/2023