Microbial Fermentation Manufacturing: Advances through single-use technologies

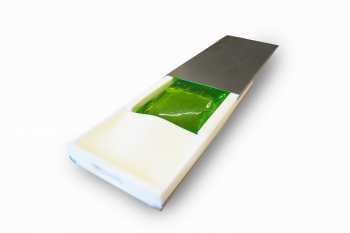

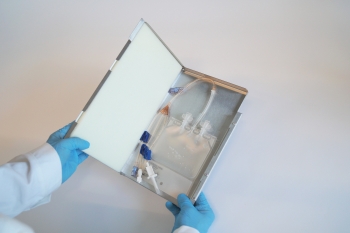

Microbial fermentation is a powerful, flexible microbiology process used to generate microbial cells or biomass such as proteins and enzymes for the production of vaccines and therapeutics. There are still some challenges to overcome. Many of these challenges in fermentation manufacturing can be solved by replacing traditional systems with single-use technologies.