Single Use Support

Welcome to Single Use Support

Reduce product loss with a trusted partner

We provide advanced fluid management solutions around single-use technologies for the Biopharma Industry to increase patient safety. Discover our products around primary packaging, single-use bag protection, freeze-thaw processes, single-use filling-filtration, and logistics of your substances.

Modular and customizable Solutions - for all modalities

Our customers trust in us:

Product Overview

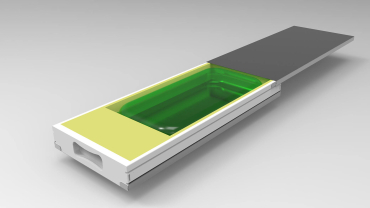

RoSS® Shell | Protecting single-use bags

The safest transport solution for all available single-use bioprocess containers. Robust. Scalable. Single-use bag independent.

RoSS.FILL CGT | Fill-Filtration | 1mL-1000mL

1mL-1000mL: Fully automated cell and gene filling machine system for aseptic filling of multiple small single use bags. Special designed for use in cell & gene therapies with batch sizes at low volumes. With its high filling accuracy, the platform provides filling from 36 up to 128+ bags with one or several racks.

IRIS Manifold | Single-Use Assemblies

As an expert in single-use solutions, we have made it our goal to deliver vendor agnostic single-use assemblies manufactured at highest quality standards in ISO 7 cleanrooms and sterilized within shortest lead times. Prevent downtime and ensure an uninterrupted supply chain in compliance with GMP and regulatory requirements with our single-use manifold assemblies using silicone tubing and connectors of your choice.

RoSS.pFTU Large-Scale | Plate Freeze & Thaw

Up to 400L: Our large scale freezing platform system is a plate-based pharmaceutical freezer and thaw unit for any scale and batch size. Well-established RoSS.pFTU large scale is compatible with single-use bags of all sizes and manufacturers. The hybrid solution offers freeze-thaw capabilities for bags and bottles up to 400L in one platform.

RoSS.FRDG | Ultra Cold Storage Freezer

RoSS.FRDG is an ultra cold storage fridge for frozen drug substances in different sizes. The ultra cold freezer keeps the desired set point temperature down to -75°C. RoSS.FRDG offers highest storage density, is fully movable and can be modularly adapted to your individual needs.

All Solutions

Find your product solutions from platform systems to consumables and after-sales services.

Tell us your needs!

Send us a message, we will answer it immediately.

WE ARE HIRING

Ready for a new Challenge?

News

Find here the most recent news articles, press releases and product news from Single Use Support.