Case Study: How to save storage space with single use bags

Table of contents

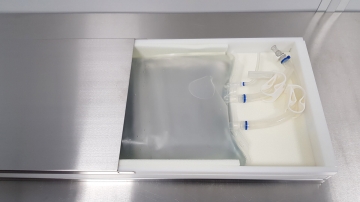

ShowStorage capacity is limited at most biopharmaceutical manufacturing plants. Single use bags with its flat shape is predestined for stacking and offer great solutions to increase storage density on-site but also for shipment.

A US-biopharma company has changed its primary packaging of drug substance to single use bags in order to achieve an improvement of storage space, among other reasons. At first, the high expectations were not met. Only the combination of single use bags and RoSS shells increased the storage density due to its rectangular geometry and its possibility to stack. This was the initial starting point to work with Single Use Support on both goals: increase storage density during international transportation with holding the temperature lower than -50°C and increasing the storage density for in-plant storage.

The following case study sheds light into the measures that have been taken with RoSS.SHIP and RoSS Accessories to reduce storage room capacities and the number of pallets for shipment which in turn saved a lot of expenses.