Biopharma packaging - requirements and solutions

Table of contents

ShowPharmaceutical packaging is becoming an increasingly important topic in the pharmaceutical industry, with the rise of biopharmaceuticals being a key driver of growth in this area. As the use of biopharmaceuticals continues to increase, so does the demand for specialized packaging solutions.

The packaging and labeling of biologics and drug products presents unique challenges due to their complex and sensitive nature, requiring specialized packaging solutions for safe transport and storage in frozen state.

In this article, we will explore the benefits of customized packaging solutions from contract packaging organizations, the use of single-use systems for biopharma packaging, and the trends and challenges in the field.

We will also discuss the importance of sustainability in pharmaceutical packaging, the advantages of single-use systems in this regard, and how customized packaging solutions can meet specific requirements at all scales of biopharmaceutical processing.1

Special packaging requirements for Biologics

Biologics are complex and sensitive to their environment and require advanced packaging to protect their therapeutic benefits. Compared to small molecule drugs, biologics have more intricate packaging needs, and the use of ordinary glass is not sufficient. Glass packaging vials, syringes, closures, or inserts may interact with the chemicals on the surface of the drug, causing contamination.2

Safe transport of APIs (Active pharmaceutical ingredients) can be guaranteed at the correct freezing temperature. Packaging solutions must therefore meet the requirements for freeze-thaw conditions.

Biologics are typically produced in large quantities and are transported in bulk to the fill & finish site. The drug delivery of these bulk drug substances requires specialized packaging that can maintain the appropriate temperature range during transit and the use of cold chain packaging is essential for maintaining the required temperature range during transport.

Biopharma packaging solutions

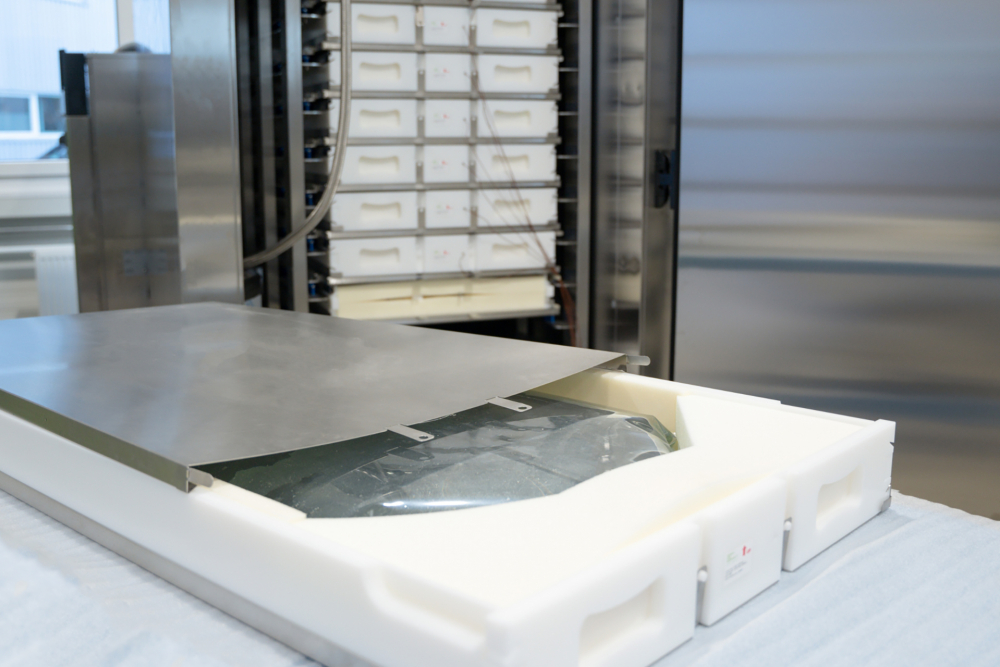

Packaging solutions for drug substances are mostly built in different layers. A distinction is made between primary and secondary packaging, but there is also tertiary packaging.

While primary and secondary packaging complement each other to ensure the protection of the liquids, tertiary packaging is mostly used to stack the products efficiently and to load them safe and efficiently into transport facilities.

Biopharma packaging based on a Single Use Support case

Up to 1000 liters of drug substance must be brought from A to B within the shortest possible time. How are the liquid substances packed appropriately?

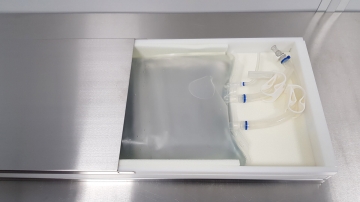

- Filling takes place automatically in the (primary packaging) single-use bags.

- The bags are protected by a (secondary packaging) shell in which the bags with the liquids can be frozen to the ideal temperatures and are thus optimally prepared for transport.

- Finally, the individual single-use shells are stowed in a (tertiary packaging) cold-chain shipping container, in which the temperature is kept constant during transport. The container can now go on its journey.

Biopharmaceutical packaging: Safety first

In the production of pharmaceutical products, adherence to strict guidelines such as current Good Manufacturing Practices, requiring certifications from FDA (Food and Drug Administration), EMA (European Medicines Agency) or ASTM d4169 is crucial for ensuring the quality and safety of drug substances and medical devices.

Similarly, the packaging of biologics must also be given strict attention by providers to ensure safe manufacturing process, storage and transport, as the risks of contamination or product loss can jeopardize its integrity and sterility. Automated process solutions can help prevent human errors in filling. Single-use bags provide optimal quality control and protection for high-value biologics and reduce the risk of contamination in comparison to reusable durable containers.3

Efficient packaging reduces operating costs

Efficient packaging solutions do not only reduce environmental impact, but they also decrease operating costs in the pharmaceutical healthcare industry and their supply chain.

Efficient packaging is done space-saving to avoid empty spaces and automated to avoid errors and slow processing. When packaging is more efficient, there is less waste and fewer damaged products, leading to fewer product losses and cost savings for companies.

Automation also plays a key role in reducing costs, as fully automated processes can help to minimize human errors and reduce the need for qualified personnel.

Additionally, packaging that is designed to be space-efficient for storage and delivery systems can help to further reduce costs by maximizing storage density and minimizing shipping costs. As technology and eco-friendly packaging continue to advance, the cost of pharmaceutical packaging is expected to decrease, benefiting both manufacturers and consumers.

If you want to learn more about drug substance shipping challenges and solutions, read the article about shipping of pharmaceutical liquids.

Sustainability in biopharma packaging

In the biopharma industry and life sciences, sustainability is becoming an increasingly important consideration in drug development, packaging design and packaging materials. One way this is being addressed is through the use of single-use bags and shells, which can be more environmentally friendly than multi-use options that require cleaning and sterilization.

Single-use bags are a widely used primary packaging option for the safe storage and transport of frozen drug substances. Nevertheless, studies suggest that single-use technologies are more environment-friendly than stainless-steel systems.4

However, there is also a growing push to develop more sustainable multi-use options for secondary packagings. Packaging companies like Single Use Support is working on innovative solutions, such as multi-use shells for single-use bags, to reduce waste in the packaging process.

With the focus on eco-friendly options increasing, the use of sustainable pharma packaging is set to become more widespread. Nevertheless, also the single-use RoSS shell contributes to sustainable secondary packagings, since its few components are easy to recycle.

Single Use Support’s tertiary packaging materials for outbound shipping are selected to fulfill sustainability criteria. The card boxes used are out of 80% recycled material and the standard pallet boxes to supply customers are highly suitable for recycling. Learn more about recycling of a single-use bag shell in our article: Mission completed – and now? How RoSS® Shell is to be recycled.4 5

Customized requirements: From lab scale to large scale

Customized packaging solutions are necessary to meet the specific requirements of pharmaceutical manufacturing at all scales, from lab to large volumes of several thousand liters. For example, in the case of CAR-T cell therapy, small, safe packaging and high-quality solutions are required, while bulk drug substances need larger volume solutions.

Single-use packaging offers an ideal solution to respond to these individual requirements. In the next paragraph, we will discuss how single-use packaging has become a state-of-the-art solution for the biopharmaceutical industry to meet customized packaging needs.

Advantages of single-use systems for packaging of biopharmaceuticals

Single-use systems have become increasingly popular for pharmaceutical companies and the packaging of biopharmaceuticals due to their numerous advantages. One major advantage is their scalability, which means that single-use systems can be used for both small-scale and large-scale productions.

In addition, single-use systems are more sustainable than traditional multi-use systems, as they generate less waste and do not require the energy-intensive cleaning and sterilization processes that multi-use systems do.2 Another significant benefit of single-use bioprocessing is the high level of safety, as disposable systems minimize the risk of product loss and contamination.

- Global Biologics Market Outlook, https://www.expertmarketresearch.com/reports/biologics-market, Published

- The glass ceiling: The advantages of polymers over glass in biologic drug delivery, https://pharmaceuticalmanufacturer.media/pharmaceutical-industry-insights/the-glass-ceiling-the-advantages-of-polymers-over-glass-in-b/, Published 2016

- Guidance for Industry: Container Closure Systems for Packaging Human Drugs and Biologics, https://www.fda.gov/media/70788/download, Published 1999

- Streamlined life cycle assessment of single use technologies in biopharmaceutical manufacture, http://dx.doi.org/10.1016/j.nbt.2022.01.002, Published 2022-01-08

- How is Sustainability Incorporated into Pharmaceutical Packaging?, https://www.news-medical.net/life-sciences/How-is-Sustainability-Incorporated-into-Pharmaceutical-Packaging.aspx, Published 2023