Bioprocess solutions: Advancements with single-use technology

Table of contents

ShowBioprocess manufacturing has seen remarkable advancements through the utilization of single-use technology. This shift in process development brings numerous advantages for stakeholders in the pharmaceutical industry, facilitating the production of innovative diagnostic and therapeutic tools.

In this article, we'll explore the various aspects of bioprocess engineering, its benefits, stages, and how single-use technologies have led to improvements in the biopharmaceutical and biomanufacturing industry.

Bioprocess definition

Bioprocess engineering is at the heart of biotechnology, encompassing a wide array of processes that employ living cells, microorganisms, or their components to produce a diverse range of biopharmaceuticals, vaccines, enzymes, and other biotherapeutics. Bioprocessing merges principles of biochemistry, genetic engineering, and chemical engineering to harness the biological potential of microorganisms in the development of cutting-edge products for the pharmaceutical and biotech industries.

As bioprocess technology continues to evolve, improving manufacturing processes plays an increasingly pivotal role. Through rigorous process optimization, automation, and the implementation of single-use technologies, bioprocess engineering stands as a cornerstone of the biopharmaceutical and biotech industries, driving forward the frontiers of science and technology.

Read more: Bioprocessing - everything you need to know

Benefits of bioprocess manufacturing

In life sciences and medicine, bioprocessing emerges as a powerful catalyst for positive change, offering a multitude of transformative benefits. This technology-driven approach not only shapes the landscape of research and healthcare but also holds the potential to revolutionize the way we combat diseases and improve the overall quality of life.

Foremost, bioprocessing fuels innovation and research in medicine. It serves as the engine behind the development and production processes of cutting-edge pharmaceuticals, vaccines, and biotherapeutics, contributing to medical breakthroughs that have a profound impact on human health. From monoclonal antibodies (mAbs) with a high specificity for a distinct antigen to advanced genetic-engineered therapies, bioprocessing enables the creation of novel treatments that were once deemed unattainable.

Examples of bioprocessing – what it can achieve

Bioprocessing showcases its remarkable potential through a myriad of applications across diverse domains. One prominent example lies in vaccine manufacturing. Bioprocessing plays a pivotal role in cultivating the necessary microorganisms or cell cultures to produce the main raw materials of vaccines, addressing global health challenges and safeguarding populations against infectious diseases.

Additionally, in biopharmaceutical manufacturing, bioprocessing technology is the cornerstone of producing complex therapeutic proteins, such as monoclonal antibodies and recombinant enzymes. These have become state-of-the-art tools to engineer life-saving medicines.

In cell therapy, bioprocessing enables the growth and manipulation of specific cell lines, holding the promise of revolutionizing regenerative medicine and personalized healthcare. Moreover, in microbiology, bioprocessing is indispensable for understanding and harnessing microorganisms for various applications, from bioremediation to biofuel production.

However, the fields of application of bioprocessing is increasingly growing, with some major achievements listed below:

- Insulin production

- Viral vector production

- Monoclonal antibody therapeutics for cancer therapy

- CAR-T cell therapy

- Enzyme replacement therapies

- Biosimilar production

Bioprocess stages and how they benefit from single-use technologies

Within a bioprocess workflow, several key stages are transformed by the adoption of single-use technologies. These innovations provide versatility, minimize contamination risks, and enhance cost-efficiency.

From upstream processing including fermentation to downstream processing, single-use technologies streamline the biomanufacturing process, ensuring high product quality and reducing the environmental impact of traditional stainless steel systems.

Upstream bioprocessing

Upstream processing is one of the initial phases in bioprocessing, encompassing the cultivation and preparation of cells or microorganisms for further biomanufacturing. The implementation of single-use technologies in this stage can improve the entire process.

In cell culture, single-use bioreactors, bags, and containers can replace traditional stainless steel systems. This transition offers greater flexibility and cost-efficiency, permitting easier scale-up for large-scale production. The utilization of single-use bioreactors eliminates the need for extensive cleaning and sterilization, thus minimizing the risk of cross-contamination. Fed-batch processes, commonly employed in upstream processing, also benefit from single-use technologies and consumables, allowing precise control of nutrient addition.

This is how the integration of single-use solutions in upstream processing enhances production throughput, reduces costs, and facilitates the scalability of bioprocesses.

Fermentation

Fermentation is a central step in upstream bioprocessing, where microorganisms or cells perform the task of delivering valuable bio-based products. The integration of modern bioprocess technology has had a considerable impact on this critical phase.

Microbes, the workhorses of microbial fermentation, now thrive in controlled, single-use bioreactors. These reactors allow for precision in managing glucose, a primary substrate, and other nutrients, ensuring optimal growth and product formation, but do not require extensive cleaning.

When comparing them with the efforts that come with the use of stainless steel tanks – such as CIP (Clean in Place) and SIP (Sterilization in Place) –, single-use bioreactors not only allow manufacturers to save valuable time and human workforce, but also to reduce the environmental impact that comes with the water and energy consumption of traditional cleaning and sterilization processes.

Seed train intensification

Seed train intensification is an advancement in upstream bioprocessing, streamlining the preparation of cells for bioreactor inoculation. This approach aims to accelerate the production timeline, mitigate costs, and minimize contamination risks associated with traditional methods.

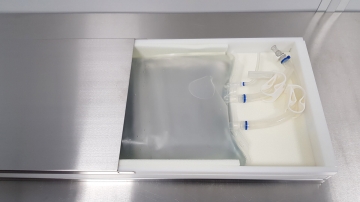

The high-density working cell bank is aliquoted into single-use bags, facilitating efficient cryopreservation. These cryopreserved aliquots serve as working cell banks for inoculating intermediate bioreactors within the seed train. This innovative strategy enables rapid scale-up of cell production while maintaining product quality.

Downstream bioprocessing

Downstream processing marks the final stage of bioprocessing, where the focus shifts from bioproduction to the purification, chromatography and formulation of the desired bioproducts. In this intricate phase, a multitude of techniques and technologies work harmoniously to extract, refine, and package the valuable compounds.

Filtration and centrifugation, integral to downstream processing, are optimized for the separation of biomass and target molecules. Chemical engineering principles guide the purification process, ensuring the isolation of the desired compounds. Not only at this stage, process control is vital to maintain product purity and quality.

Increasingly, single-use technologies find their place in downstream processing. Single-use bags and systems facilitate homogenization, filling, and dispensing of the final product, enhancing efficiency while minimizing cross-contamination risks.

Furthermore, they are an ideal basis for further processing steps, including freezing, storing, transport and thawing. Here, single-use technologies have proved to provide efficient approaches to maintain product quality and reduce the risk of product loss – be it the breakage of single-use bags in vaccine production or cross-contamination when switching between different production lines of cell therapies.

7 Advantages of bioprocess solutions using single-use technologies

In bioprocessing, the adoption of single-use technologies brings forth a set of advantages for the entire biopharma industry. One of the key benefits of single-use technologies in bioprocessing is the increased flexibility that they bring: They can be easily re-configured for different applications, indifferent to the scale or the processed product.1

But this is not the only advantage of single-use bioprocess solutions. Nevertheless, these innovative systems not only improve production, but also align with sustainability and quality assurance.

- Reduced contamination risk: Single-use systems minimize the chances of contamination, safeguarding the purity of bioproducts.

- Cost-efficiency: These systems eliminate the need for labor-intensive cleaning and sterilization, thereby reducing operational costs.

- Minimized need for human workforce: By implementing automated systems based on single-use technologies, staff requirements can be reduced.

- Enhanced flexibility: Single-use technologies grant manufacturers agility in production, enabling swift changeovers and adapting to diverse product needs.

- Scalability: Whether it's a small batch or large-scale production, single-use systems accommodate the demand, facilitating growth.

- Environmental sustainability: Single-use solutions reduce water and energy consumption, contributing to more eco-friendly manufacturing practices.

- Quality assurance: Precise process control and automation guarantee consistent product quality, in compliance with rigorous regulatory standards.

Source2

Bioprocess solutions by Single Use Support

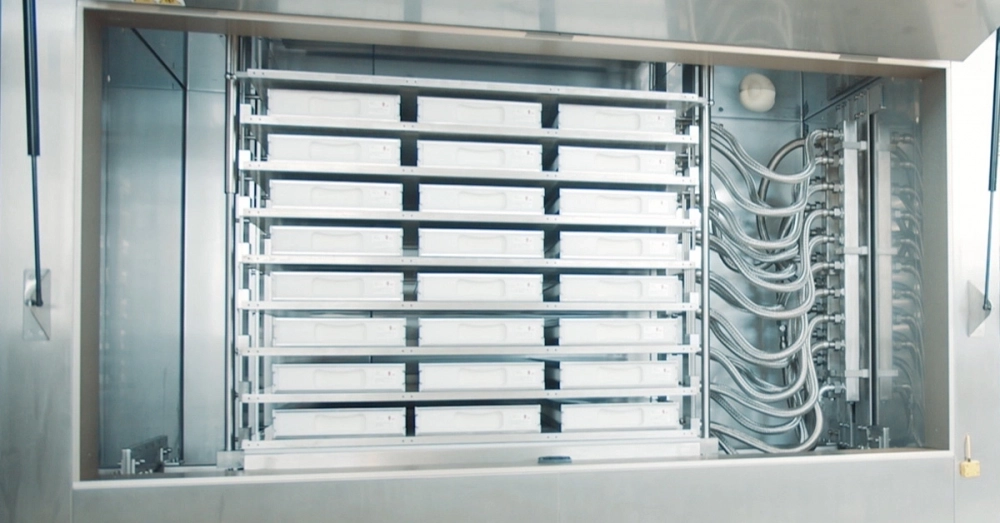

Single Use Support has developed a product line-up that covers the whole bioprocess workflow. Not only does this include single-use consumables, such as bags in different sizes and respective protective packaging for subsequent logistics, but entire automated fluid management systems. As these systems are extremely flexible, rapid changeovers between different production lines and upscaling production processes are conducted with ease.

Moreover, solutions for single-use based freezing and thawing with plate freezing technology as well as cryogenic freezers and ULT storage freezers make sure that cold chain requirements are reliably met along the supply chain of sensitive biologics.

The product portfolio of Single Use Support is completed by a wide array of assemblies and consumables, such as for aseptic sampling and vendor-agnostic bioprocess containers in different sizes. By aligning these innovative solutions into their individual production processes, manufacturers can profit from the countless benefits that come with single-use bioprocess solutions.

Recommended articles

Single Use Support has developed a product line-up that covers the whole bioprocess workflow. Not only does this include single-use consumables, such as bags in different sizes and respective protective packaging for subsequent logistics, but entire automated fluid management systems. As these systems are extremely flexible, rapid changeovers between different production lines and upscaling production processes are conducted with ease.

Moreover, solutions for single-use based freezing and thawing with plate freezing technology as well as cryogenic freezers and ULT storage freezers make sure that cold chain requirements are reliably met along the supply chain of sensitive biologics.

The product portfolio of Single Use Support is completed by a wide array of assemblies and consumables, such as for aseptic sampling and vendor-agnostic bioprocess containers in different sizes. By aligning these innovative solutions into their individual production processes, manufacturers can profit from the countless benefits that come with single-use bioprocess solutions.

- Advanced Liquid Transfer with Single-Use Systems, https://bioprocessintl.com/sponsored-content/advanced-liquid-transfer-with-single-use-systems/, Published 20.10.2022

- Biopharmaceutical processing – how disposable solutions increase safety and efficiency, https://www.susupport.com/knowledge/single-use-technology/single-use-bioprocessing-pays-switch-single-use-systems, Published 06.03.2023