Why should RoSS.SHIP be your shipping container in biopharma?

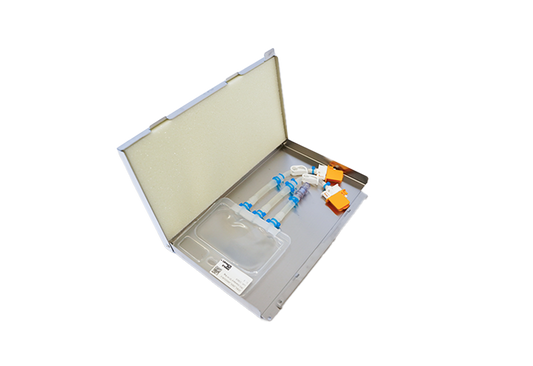

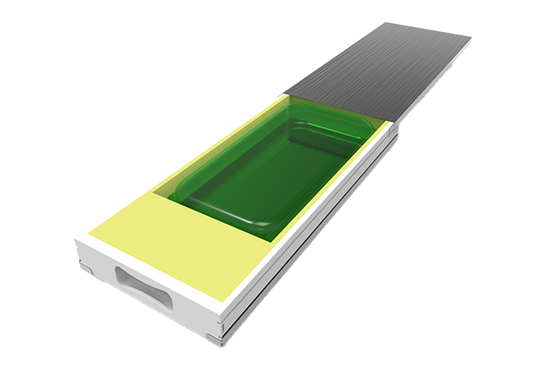

RoSS.SHIP holds up to 55 RoSS® shells – depending on its sizes – in a compact volume. Most frozen substances can be stored and shipped in a protected manner and in compliance with international standards.

The statically highly solid RoSS.SHIP stainless steel container is designed for passive cooling with cooling gel, “phase change materials” (PCM), or dry ice pellets or blocks – depending on your temperature requirements and preferences.

For our RoSS.SHIPs both options, Top Loading and Front Loading are available. With Top Loading, easy re-icying is possible if the transport takes longer than planned without temperature excursion.

Optionally, the geographical location as well as the interior temperature of the RoSS-SHIP container can be tracked and monitored 24/7 via GPS or G-Force tracking.