Enhancing sustainability in the pharmaceutical industry with single-use technologies

Table of contents

ShowWith climate change having become a reality, there is an increasing need for sustainability in everything we do. Major industries like biopharma or the life sciences in general need to rethink their production processes in order to become carbon neutral, meaning that the CO2 emissions are to be set net zero: Only by utilizing renewable energy and reducing overall energy consumption as well as by introducing initiatives to decrease greenhouse gas and other emissions can they make sure to have an environmental impact.

With the improvement of production processes and the optimization of supply chains, biopharma and pharma companies can improve environmental sustainability but also enhance value. Furthermore, by providing access to affordable drugs and medical devices to developing countries with poor and underfunded healthcare systems, pharmaceutical companies are contributing to social, and not only environmental sustainability.

Negative impact of the pharmaceutical industry on our environment

If we want to change the current speed of climate change and levels of impact on our ecosystem, we all need to do our part. And while major players in the pharmaceutical industry have been implementing initiatives for decades, controlling emissions of air and water pollutants in order to minimize damage to our ecosystem is not enough:

According to data provided by analytics provider IQVIA, around 500 companies (the ones selling 80 percent of the global volume of pharmaceutical products) need to come together and drive lasting and sustainable initiatives in order to achieve lasting change and reduce the industry’s carbon footprint.

Health systems and life sciences as a whole should be front-runners in limiting the impact of climate change, as they are not only randomly concerned with the human health and well-being, but at the heart of public health.1

Solutions to advance sustainability

However, achieving sustainability in any manufacturing industry can be a challenging task due to the need to balance what is good for the environment with what is good for the business. This is why in 2005, a number of pharma stakeholders came together to develop strategies against the industry’s negative impact on our ecosystem.

Since then, they have been working on promoting environmental protection by driving the use of greener chemistry to realize their formulations as well as using renewable resources and engineering approaches in the production of pharmaceutical products and therapies.

Sustainability strategies that have or should be implemented by pharmaceutical manufacturers include, but are not limited to,

- the introduction of circular economy to reduce waste as well as greenhouse gas emissions and design greener products

- the redesign of the supply chain to introduce greater transparency and track emissions

- the implementation of standardized metrics and increase of environmental regulations

One approach to achieve one if not several of the above mentioned sustainable development goals is the utilization of single-use technology. As illogical as it may seem, single-use technology is generally more environmentally friendly than traditional solutions. Less than 0.01% of global plastic waste generated annually stem from single-use technologies used in biopharma.2

Download Case Study

Case Study: Refurbishing single-use systems

In collaboration with a US-based vaccine innovation company, Single Use Support has implemented a reusability model for single-use systems. To ensure secure cold chain transport between CMOs, 125 trolleys - each carrying 10 reusable RoSS® shells with 50L single-use bags - circulate within a closed, sterile, and controlled loop. Download our Case Study.

Single-use vs. Stainless Steel: Sustainability Check

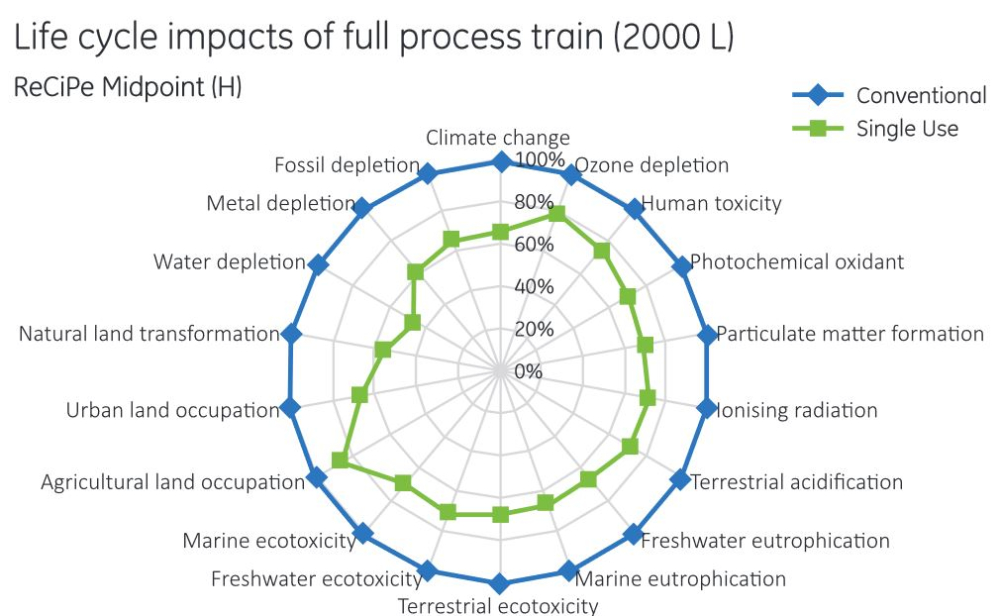

Different life cycle assessment studies have shown that by switching from stainless steel to single-use systems the biopharma and pharma industry can significantly reduce their carbon emissions as well as energy and water consumption.

This is due not least to reduced cleaning requirements - meaning less solvents, streamlined procurement resulting in a smaller carbon footprint and less capital investment, along with more flexibility, and reduced risk of cross-contamination.

Nonetheless, throughout their decision-making processes, manufacturers of single-use technologies are aware of the fact that their increasing deployment in the industry requires strategies to ensure long-term sustainability. The implementation of sustainable pharmaceutical solutions into their value chain, however, requires the contribution of all parties involved in the product life cycle: manufacturers of raw materials, components, and single-use systems as well as carriers, users and waste treatment companies.3

Environmental impact of single-use technologies

The impact of plastic waste on our environment and our planet is not disputable. However, it needs to be pointed out that this waste does not come from the biopharma industry as it is subject to strict regulatory guidelines that are governing the collection, decontamination, and disposal of materials used in drug development and production.

Furthermore, in line with sustainability strategy guidelines, manufacturers of single-use technologies are obliged to facilitate the separation of the product into its base materials after use. Therefore, most single-use products are very easy to disassemble and recycle.4

Waste management in Biopharma single-use industry

In general, there are more factors that influence sustainability than only plastic waste. It is the holistic view on all environmental aspects including the required resources of water, chemicals, material processing etc., the impact on agricultural or urban land occupation, on ozone depletion or on ecotoxicity that help to evaluate the total impact on sustainability. When comparing different solutions in biotechnology, single-use technology is more environmentally friendly than traditional multi-use stainless-steel solutions. The reason behind this observation is mainly the need to elaborately clean multi-use technologies, such as stainless-steel technologies. Process freeze tanks, for example, must be cleaned with high water pressure, chemicals and other treatments before re-use which leads to extensive environmental harm.

The comparison between the lifecycle-assessment of single-use and conventional (durable) facilities are shown in Fig.2 in detail.5

The industry is about to acknowledge that sustainability is a mutual long-term goal where many parties are involved. All contributions and initiatives to make the industry even more environmentally friendly are a good step to make both the industry and our environment sustainable whilst maintaining the quality and sterility of biopharmaceutical products.

EcoVadis Sustainability Rating

Single Use Support fullfills the rating criteria of the EcoVadis Sustainability Rating. This involves a regular monitoring of sustainable aspects in global supply chains involving innovative technology and sustainable process approaches.

- Environmental Sustainability in Pharma, https://www.iqvia.com/-/media/iqvia/pdfs/library/articles/environmental-sustainability-in-pharma-iqvia.pdf?_=1651155700295, Published

- Advancing sustainability in the pharmaceutical industry, https://cen.acs.org/acs-news/comment/Advancing-sustainability-pharmaceutical-industry/98/i17, Published May 2, 2020

- Is Sustainability Possible With Single-Use Technology?, https://www.bioprocessonline.com/doc/is-sustainability-possible-with-single-use-technology-0001, Published August 12, 2015

- What About the Environmental Impact of Single-Use Technology on Sustainability?, https://ispe.org/pharmaceutical-engineering/ispeak/what-about-environmental-impact-single-use-technology, Published 15, October 2020

- GE HealthcareLife SciencesAn environmental life cycle assessment comparison of single-use and conventional bioprocessing technology, https://docplayer.net/20413850-Ge-healthcare-life-sciences-an-environmental-life-cycle-assessment-comparison-of-single-use-and-conventional-bioprocessing-technology.html, Published