Automated aliquoting system - for small & large volumes

Table of contents

ShowAutomated aliquoting systems are becoming more and more popular all over the life sciences sector, as well as in biopharmaceutical production. Here, precision is a fundamental requirement in fluid management. From aliquoting to liquid handling, achieving accuracy and efficiency is a continuous challenge. Automated systems provide a feasible solution, streamlining workflows and enhancing assays.

In this article, we will explore the impact of laboratory automation, particularly how automated liquid aliquoting solutions optimize reagent handling and throughput.

What is an automated liquid handling system?

An automated liquid handling system is a sophisticated instrument utilized not only in lab automation but also in the biopharmaceutical industry. Its primary function is to optimize the process of liquid transfer and dispensing, ensuring precision and efficiency. These systems are integral to a wide array of scientific and research applications, providing a high level of accuracy in fluid handling.

Automated liquid handling systems are indispensable for a variety of assays and tasks, where the precise and reproducible manipulation of reagents is of paramount importance. They excel at automating repetitive and time-consuming tasks, thereby reducing the potential for human error.

Equipped with solutions like liquid handlers and other labware, these systems are not confined to laboratory settings alone; they are also extensively employed in the biopharmaceutical industry. In both research laboratories and biopharmaceutical manufacturing facilities, automated liquid handling systems contribute to enhanced efficiency and consistency, ensuring the reliability and reproducibility of critical processes.

From homogenizers to automated aliquotation systems: Applications of liquid handlers

Automated aliquoting systems are dynamic solutions that find application across a multitude of fields, offering precision and efficiency in liquid handling tasks. Here is a glimpse into several fields where these systems play a pivotal role:

Vaccine production: Automated aliquoting systems are critical in the precise dispensing of liquids for vaccine manufacturing into single-use containers, ensuring consistency and adherence to Good Manufacturing Practice (GMP) standards.

Cell and gene therapy production: The smaller the volume, the more important is accuracy. Systems for CGT applications are essential for accurately handling critical components like viral vectors, cell cultures, and gene therapies in cell and gene therapy production, meeting the stringent requirements of low-volume batch sizes.

Next generation sequencing (NGS): In genomics, automated aliquoting systems enable the precise distribution of nucleic acid samples and reagents, a critical step in NGS workflows, e.g. DNA normalization,

Clinical diagnostics: Automated aliquoting systems are employed in clinical laboratories for tasks like sample preparation on microplates and well plates, assay development and labeling, ensuring reliable and accurate results, e.g. in PCR testing.

Drug discovery: In pharmaceutical research, these systems facilitate the distribution of compounds, reagents, and samples in high-throughput screening processes, expediting drug discovery.

Biobanking: Biobanks like cell banks use automated aliquoting systems to precisely aliquot and store biological samples, ensuring the integrity and traceability of specimens.

Challenges in pharmaceutical aliquoting – why automation is key

In pharmaceutical aliquoting, several challenges can impede the efficiency and precision of critical liquid handling processes. Automation has emerged as a pivotal solution to address these challenges, offering a range of benefits in pharmaceutical manufacturing and research.

Pharmaceutical production often involves diverse batch sizes, from small-scale research to large-scale manufacturing. Automated aliquoting systems provide the flexibility to handle varying batch volumes efficiently, ensuring consistent and precise liquid distribution regardless of the scale.

Compatibility with different systems, containers, and formats is equally essential in pharmaceutical operations. Automated systems are designed to seamlessly integrate with a variety of packaging options, workstations, and configurations, reducing integration complexities and enhancing adaptability.

Cross-contamination is a critical concern in life sciences and clinical applications. Automated aliquoting systems incorporate features that minimize the risk of contamination, such as automated sample preparation and validation, ensuring the integrity of samples and data.

Manual aliquoting processes can be resource-intensive and susceptible to human error. Automation and solutions like robotic arms or pipetting devices streamline the process, reducing the need for manual intervention. This not only enhances efficiency but also optimizes resource allocation and labor utilization, leading to cost-effective operations.

Automated aliquoting systems also offer a high level of reproducibility, ensuring that each aliquot matches the intended specifications. This precision is essential for maintaining consistency and data integrity, particularly in experiments like ELISA assays and other critical applications.

Automated aliquoting with Single Use Support

Single Use Support offers a comprehensive range of automated aliquoting solutions within the RoSS.FILL product line. These innovative systems are designed to address the diverse liquid handling needs in various industries. Let's take a closer look at each RoSS.FILL variant:

- RoSS.FILL Lab Scale: small volumes: 1ml to 1000ml

- RoSS.FILL CGT (Cell and Gene Therapy): small volumes: 1ml to 1000ml

- RoSS.FILL Bag: 1L to 1000L+

- RoSS.FILL Base: 1L to 1000L+

- RoSS.FILL Bottle: simultaneous filling of up to 20 bottles (up to 5L)

Automated aliquoting system for small volumes

The precise distribution of small volumes of liquids is a critical step in various fields, from scientific research to pharmaceutical production. Single Use Support offers two exceptional solutions under the RoSS.FILL product line: RoSS.FILL CGT and RoSS.FILL Lab Scale, each designed to streamline automated aliquoting of small batches with precision and efficiency.

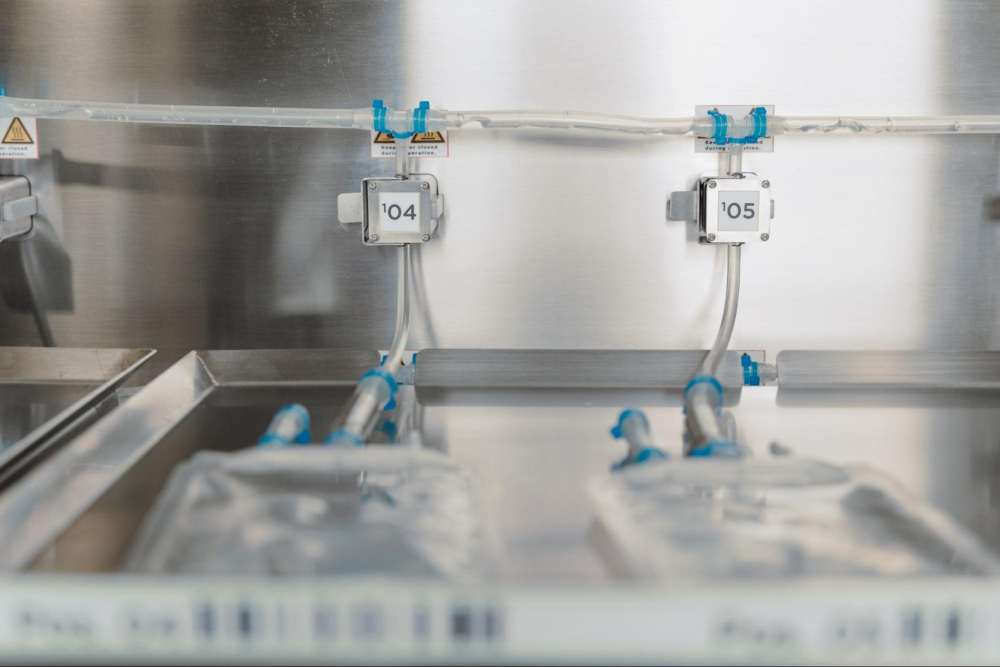

RoSS.FILL CGT is a fully automated aseptic filling system tailored for the specific requirements of cell and gene therapy production. It is particularly well-suited for applications with low-volume batch sizes. This advanced system enables the simultaneous filling of multiple small single-use bags, making it an ideal choice for handling volumes ranging from 1mL to 1000mL. RoSS.FILL CGT offers a high level of accuracy and efficiency, and it provides the option to attach more racks for enhanced throughput.

RoSS.FILL Lab Scale is a versatile automated filling platform designed for laboratory settings. With the capability to handle volumes from 1mL to 1000mL, it is adaptable to a wide range of applications in research and development. This system boasts a small footprint and state-of-the-art technology, ensuring precise and efficient liquid handling. RoSS.FILL Lab Scale is an excellent choice for labs and research facilities that require automated sample aliquoting with consistent results.

Both RoSS.FILL CGT and RoSS.FILL Lab Scale offer solutions that enhance the accuracy, efficiency, and reliability of automated small volume aliquoting, making them valuable tools in various industries, including pharmaceuticals, biotechnology, and research laboratories. With features like an automated stepper function as well as an integrated automated sealing function and labeling function, these systems contribute to the precision and consistency required for successful experiments and manufacturing processes.

Automated aliquoting system for large volumes

In liquid handling, achieving efficient, fast, and safe bulk filling processes is paramount. To do so, Single Use Support's RoSS.FILL product line includes three essential variants – RoSS.FILL Base, RoSS.FILL Bag, and RoSS.FILL Bottle –, which excel in these aspects, catering to a wide range of applications.

RoSS.FILL Bag is a versatile automated single-use aseptic bag filling machine, accommodating a wide variety of sterile connection and disconnection options. This system is capable of filling volumes up to 400L per batch with exceptional accuracy.

RoSS.FILL Base serves as a flexible platform for bulk filtration and dispensing drug substances into single-use bags. It offers limitless batch volume possibilities, with the capacity to fill several 2D single-use bags up to 500L. For even larger quantities, the system can attach a 3D single-use bag, allowing bulk filling of up to 1000L. It is the go-to choice for applications requiring high-throughput operations and exact calibration.

RoSS.FILL Bottle is a fully automated aseptic single-use bottle filling and filtration system that is designed for the precise handling of both drug and non-drug substances. Its high filling accuracy ensures consistency in every operation, making it an excellent choice for applications like drug discovery, where precision is of the essence. The system can simultaneously fill up to 20 bottles, operating as a closed system to guarantee the safety and integrity of the filling process.

These RoSS.FILL variants offer high-throughput solutions, making them suitable for applications in drug discovery, nucleic acid research, and more. They can elevate liquid handling efficiency, ensuring precise and safe bulk filling processes in a variety of fields.

Advantages of automated liquid handling with Single Use Support

Single Use Support's automated liquid handling solutions offer numerous advantages that cater to the evolving needs of various industries. One key advantage is scalability, enabling these solutions to adapt to changing production requirements seamlessly. Whether you need to process small or large volumes, these systems can efficiently accommodate your demands, making them cost-effective in the long run.

Interoperability is another strength of these solutions. They can seamlessly integrate with different systems, packaging solutions and other consumables, promoting a cohesive and efficient workflow including real-time monitoring. This level of variability is particularly valuable in industries with diverse liquid handling needs, as it ensures a high level of flexibility and operational compatibility.

Moreover, Single Use Support's use of single-use technologies adds an extra layer of flexibility and economy to these automated solutions. By incorporating single-use components, they minimize the risk of cross-contamination and reduce the need for extensive cleaning processes. This not only enhances safety but also contributes to resource efficiency.

Scalability to handle varying production volumes, interoperability with different systems, and the utilization of single-use technologies for enhanced flexibility, safety, and resource efficiency: The advantages of Single Use Support's automated liquid handling solutions make these systems indispensable in industries where adaptability, precision, and economy are paramount.

FAQs

What is automated sample analysis?

Automated sample analysis involves using specialized systems to assess and evaluate various types of samples. These systems are commonly found in laboratories, clinical settings, and quality control processes. They enable rapid and accurate analysis of chemical compounds, biological materials, and physical properties. By automating these tasks, sample analyzers ensure consistent and reliable results, even when processing large quantities of samples.

What are frequent automated liquid handling instruments?

Common automated liquid handling instruments include pipettors, tubings, primary packagings, analyzers, and dilution equipment. Pipettors provide accurate and error-free liquid dispensing, available in various configurations to suit specific needs. They often use disposable pipette tips, reducing the risk of cross-contamination. Analyzers automate sample analysis processes, supporting tasks such as clinical diagnostics and quality control. Instruments for serial dilution, like dilutors and dispensers, are frequently used in preparing samples at different concentrations.