Efficient strategies for manufacturing biosimilars

Table of contents

ShowBiosimilars are the fastest growing sector in biopharma and bear a lot of potential, but also challenges for manufacturers. As patents for different high-selling biologics run out within the next 10 years, the biosimilar industry will experience a new peak. To stay competitive, innovative technology is needed to deliver safe, effective, and high-quality products.

In this article, we explore efficient strategies for manufacturing biosimilars. We will cover aspects like optimizing cell line cultivation and purification processes, as well as the implementation of single-use technologies and advanced analytics to comply with regulatory requirements, while saving time and reducing costs.1 2 3

Manufacturing biosimilars – what to consider

There are several areas that require special consideration to produce a successful biosimilar product. These include the safe handling of biosimilars, designing the manufacturing process to be as efficient as possible to stay economically competitive, as well as finding effective ways to comply with regulatory requirements.

With the help of biotechnological advances, these areas can be optimized by streamlining the manufacturing process, reducing the need for manual intervention and potential contamination risks while increasing production speed. 4

Safe handling of biosimilars

Efficient safe handling of biosimilars during production is critical to ensure product quality, minimize contamination risks, and maintain a safe working environment for manufacturing personnel.

Manufacturers can ensure the safe and reliable production of biosimilars by implementing comprehensive safety measures and quality assurance practices, contributing to the delivery of high-quality and effective biologic therapies for patients. Furthermore, a reduction of manual processing minimizes the risks that come with the processing of potentially hazardous substances.

Read more: Safe handling of bulk drug substances

Process efficiency

When handling sensitive biological substances, time and cost efficiency are crucial. The costly and meticulous process profits from solutions that help to minimize product loss and maximize throughput.

For instance, the traditional procedure of cell culture involves stainless-steel or single-use bioreactors designed for large scale productions. This approach requires a lot of time until sufficient cell growth is reached. In contrast, seed train intensification allows more flexible manufacturing in large quantities.

By using technology that applies high cell density cultivation (HCDC), i.e. the cryopreservation of a master cell bank in single-use bags, production times are shortened, and it becomes easier to react to varying needs in the industry.

Compliance in biosimilar manufacturing

To reach cGMP compliance, manufacturers must establish a comprehensive quality management system that encompasses every aspect of production. This system includes protocols, standard operating procedures (SOPs), and thorough documentation to ensure adherence to regulatory requirements and industry standards.

Facilities must be designed and maintained according to cGMP guidelines, providing adequate space and infrastructure to support efficient and compliant biosimilar manufacturing. This includes regular inspections, maintenance, and validation of facility systems and equipment, as well as materials: Raw materials must meet established specifications for identity, purity, potency, and quality before use in production.5

Biosimilars: design and development

Developing biosimilars aims to equal a reference product in safety, quality, and efficacy. The first step in the development of a biosimilar is to characterize its reference product thoroughly. Once the biosimilar products are cultured and purified, tests and studies are performed to establish the product’s similarity.6

Manufacturing process of biosimilars – efficiency is key

In order to stay economically competitive and provide a high quality product, efficiency is crucial when manufacturing biosimilars. Standardized, automated process solutions and single-use equipment can help to streamline the production from cell line cultivation to the final product, while minimizing contamination risks and product loss and complying with regulatory requirements.

Cell line cultivation and upstream processing

By reducing human intervention during critical stages like cell line cultivation, it becomes easier to eliminate risks for cross contamination from the start of the production. Efficiency in cell line cultivation for biosimilars hinges on several key factors that can be optimized to enhance productivity and streamline the manufacturing process.

As traditional cell line cultivation in large bioreactors takes a significant amount of time, new technologies like HCDC in single-use bags are designed for more process efficiency. By preserving small batches of cell cultures at cryogenic temperatures, manufacturers are not forced to start the whole process from scratch but can fall back on preserved working cell banks.7

Downstream processing and fluid management of biosimilars

Enhanced purification efficiency leads to higher product yields, improved purity, and reduced manufacturing costs, ultimately contributing to the commercial success of biosimilar products.

Adopting single-use technologies for purification operations, such as disposable chromatography columns and filtration systems, offers advantages in terms of flexibility, scalability, and reduced cleaning and validation requirements.

To ensure uniform mixtures in every single-use bag, Single Use Support has designed RoSS.PADL. The homogenizing device cools cell solutions and ensures even cell density, but is applicable to other liquids with higher viscosity and where deposits can form.

In order to accelerate aliquoting of cells and minimize contamination during filling and filtration, Single Use Support has developed RoSS.FILL. This highly scalable platform is compatible with single-use bags and bottles and is suited for aseptic filling and draining of cell solutions with a speed up to 300 liters per hour.

Freezing, storage and transportation

While traditional freezing methods often show uncontrolled freezing performances that can lead to protein alterations, controlled cryogenic freezing and advanced plate freezing achieve consistent results in terms of safety and efficiency.

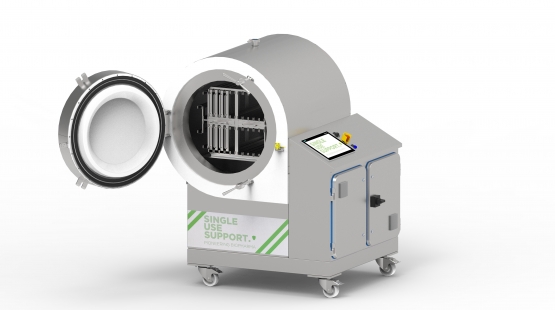

RoSS.pFTU freezes drug substances down to -80°C and enables a homogenized freezing result through plate freezing, cooling down single-use bags at controlled rates via direct contact between plate and packaging. It is compatible with single-use bags in different sizes and from any vendor.

Furthermore, Single Use Support has developed RoSS.LN2F, a cryogenic freezing system that cools drug substances down to -170°C at controlled rates. The closed platform system eliminates direct exposure of cells to liquid nitrogen and helps manufacturers reach optimal cell viability or product stability for consequent storage and transport.

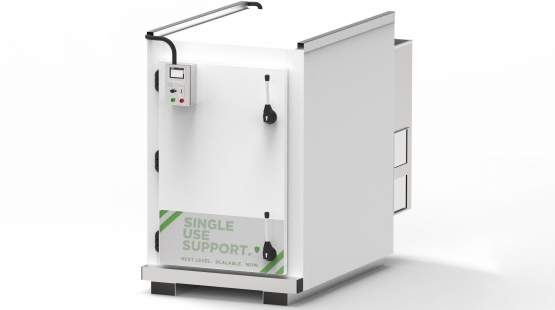

The sensitive structure of therapeutic proteins requires stable storage temperatures. Otherwise, changes in structure and product variability can be the consequence. Single Use Support’s ULT storage freezer RoSS.FRDG allows for frozen storage at temperatures as low as -75°C. It is compatible with RoSS® Shells to protect storage containers of drug substances in different sizes throughout the whole cold chain, and offers high storage density.8

Reaching goals more efficiently – with Single Use Support

The development and manufacturing process of biosimilars can be optimized by state-of-the-art single-use technologies. Safe handling profits from automated fluid management systems for biosimilars, such as RoSS.FILL, which minimize exposure and reduce contamination risks.

Single-use bags in combination with RoSS® Shell are a safe packaging option and allow for homogeneous and controlled freezing in the plate freezing platform RoSS.pFTU or RoSS.LN2F. Further, the RoSS® Shell can be used for safe storage of biologics and biosimilars in RoSS.FRDG.

The solutions designed by Single Use Support help manufacturers reach their efficiency goals more easily. Here, the scalability of single-use technologies is a driving factor and allows manufacturers to stay flexible during production.

- Biosimilars: Challenges and path forward, http://dx.doi.org/10.1007/s12257-013-0756-8, Published 2014-11-21

- Key considerations in the preclinical development of biosimilars, http://dx.doi.org/10.1016/j.drudis.2015.03.011, Published 2015-04-25

- Lynne A. Bui, Susan Hurst, Gregory L. Finch, Beverly Ingram, Ira A. Jacobs, Carol F. Kirchhoff, Chee-Keng Ng, Anne M. Ryan. “Key considerations in the preclinical development of biosimilars”. Drug Discovery Today. Volume 20, Supplement 1, https://, Published 2015

- Biosimilars: Key regulatory considerations and similarity assessment tools, http://dx.doi.org/10.1002/bit.26438, Published 2017-08-26

- Regulatory evaluation of biosimilars throughout their product life-cycle, http://dx.doi.org/10.2471/BLT.17.206284, Published 2018-03-28

- Development of biosimilars., Published 2016 Apr

- The process defines the product: what really matters in biosimilar design and production?, http://dx.doi.org/10.1093/rheumatology/kex278, Published 2017-07-03

- Use of a Design of Experiments (DoE) Approach to Optimize Large-Scale Freeze-Thaw Process of Biologics, http://dx.doi.org/10.1208/s12249-021-02034-6, Published 2021-05-12